Wafer visual detection method, wafer visual detection system and wafer damage detection method

A visual inspection and wafer technology, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult screening, mixing, wafer inspection, etc., to ensure stability and safety performance, ensure continuous operation, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

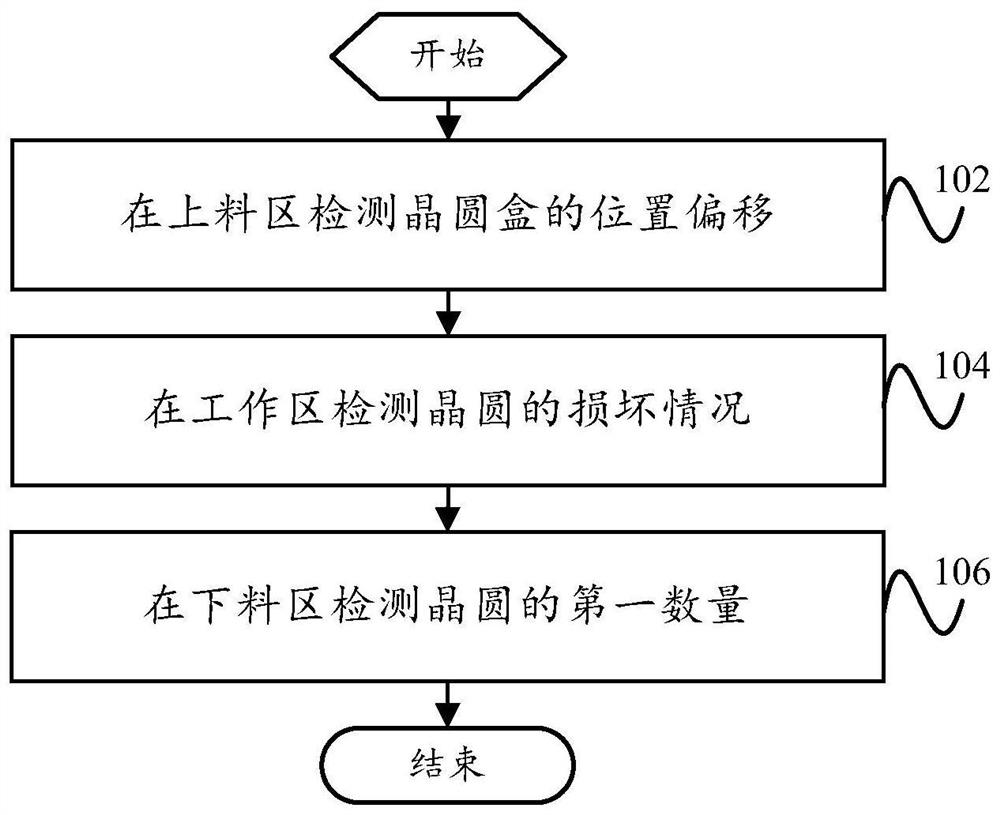

[0039] like figure 1As shown in one embodiment of the present invention, a wafer visual detection method is proposed, including:

[0040] Step 102, in the upper region detecting the positional offset of the wafer cassette;

[0041] Step 104: The damage of the wafer is detected in the work area;

[0042] Step 106: The first number of wafers is detected in the lower material region.

[0043] In this embodiment, the wafer cassette is placed on the transport line at the station by manual or other conveying assembly, and whether the position of the wafer cassette occurs at the stage, that is, the first detecting the deposition of the wafer cassette. A position of the positional offset information of the target placement area of the pre-set upper zone, so that the corresponding position adjustment is made by position offset information such that the first position of the wafer box is placed in the wafer in the wafer. The location is the same. On the one hand, the wafer cassette can be...

Embodiment 2

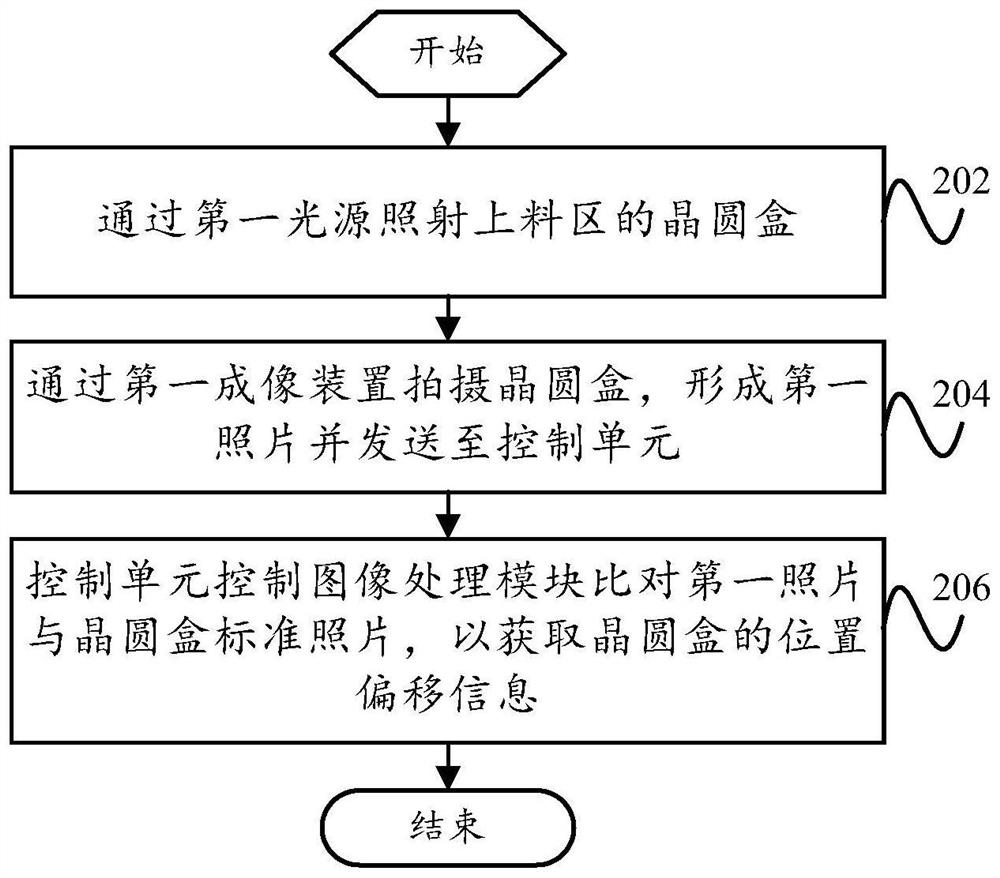

[0049] like figure 2 As shown in one embodiment of the invention, step 102, the positional offset of the wafer cassette in the charge area, including:

[0050] Step 202, through the first light source, the wafer box of the upper material is irradiated;

[0051] Step 204, pass the wafer box by the first imaging device, forming a first photo and transmitted to the control unit;

[0052] Step 206: The control unit controls the image processing module aligned with the first photo and the wafer box standard photos to acquire the positional offset information of the wafer cassette.

[0053] Wherein, the positional offset information of the wafer box includes an offset of the wafer cassette in the plaving angle of the upper region.

[0054] In this embodiment, the wafer cassette of the upper material is irradiated with the wafer visual detection system, to meet the requirements of the shooting light, sharpness of the first imaging device. The wafer cassette is photographed by the first i...

Embodiment 3

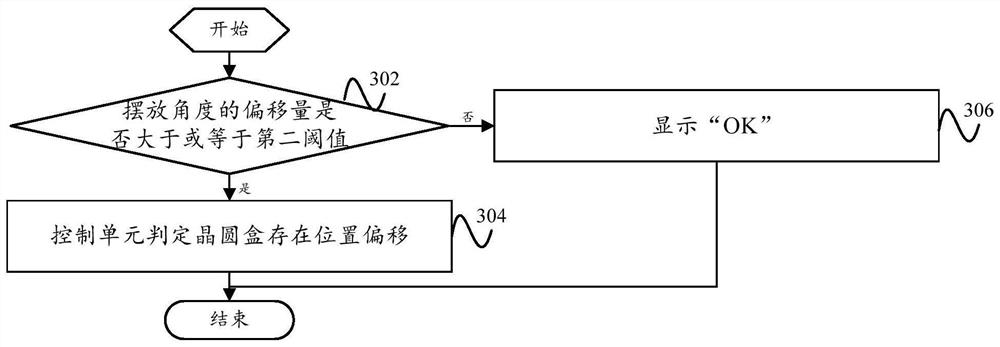

[0060] like image 3 As shown, according to an embodiment of the present invention, the positional offset information of the wafer cassette includes an offset of the wafer cassette in the plaving angle; the wafer visual detection method also includes:

[0061] Step 302, whether the offset of the placed angle is greater than or equal to the second threshold, if yes, enter step 304, if, proceed to step 306;

[0062] Step 304, the control unit determines that the wafer cassette is in position offset;

[0063] Step 306 show "OK".

[0064] In this embodiment, the extension of the wafer cassette in the wafer cassette is obtained by the first photo of the wafer cassette compared to the wafer cassette. The size relationship between the offset of the placement angle and the second threshold is compared. When the offset of the placed angle is greater than or equal to the second threshold, the crystal circular cassette is obvious, and the partial wafer is exceeded at this time. The detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com