A full gan integrated gate drive circuit with dead time control

A dead-time control and drive circuit technology, applied in electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., to achieve the effect of reducing static leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

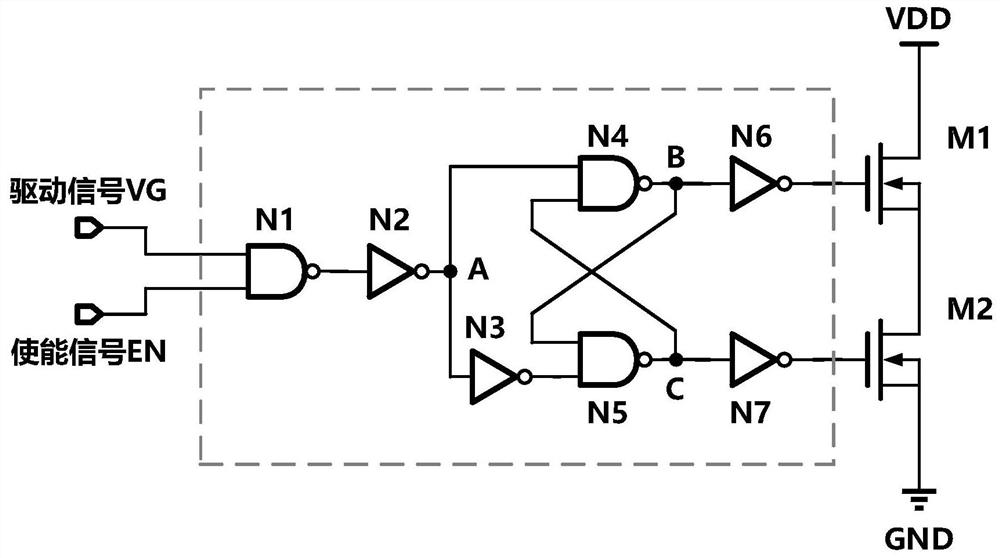

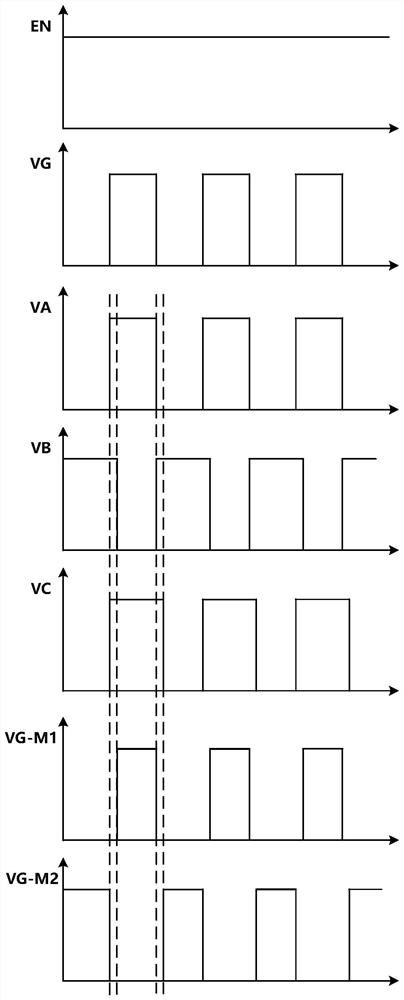

[0020] The present invention proposes a full GaN integrated gate drive circuit with dead time control, such as Figure 1 Shown, comprising 3 and non-gate circuits N1, N4 and N5, 4 non-gate circuits N2, N3, N6 and N7.

[0021] The specific circuit structure has been elaborated in the content portion of the invention, which will not be repeated here.

[0022] The following embodiment of the present invention in conjunction with the accompanying drawings to provide a half-bridge circuit pass-through protection circuit working principle and process in detail:

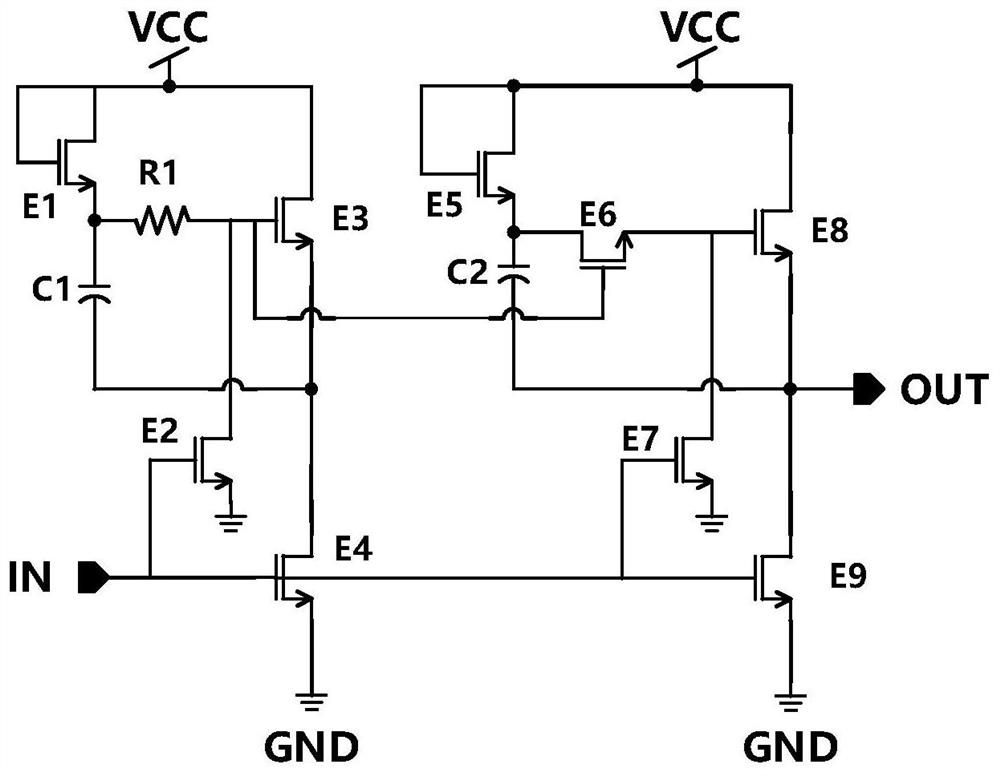

[0023] as Figure 3As shown, the non-gate circuit contains nine transistors E1, E2, E3, E4, E5, E6, E7, E8, and E9, two capacitors C1 and C2, and one resistor R1. Among them, E1, E2, E3, E4, C1 and R1 constitute the secondary side of the non-gate circuit, and E5, E6, E7, E8, E9 and C2 constitute the main side of the non-gate circuit. Transistor E7 in the main stage side plays the role of pull-down the gate potential of transistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com