A fuel injector for high pressure common rail fuel injection system

A fuel injection system and high-pressure fuel injection technology, applied in fuel injection devices, charging systems, machines/engines, etc., can solve problems such as increasing manufacturing difficulty, process cost, and difficulty in ensuring the reliability of ball valves, reducing leakage risks, The effect of reducing static leakage and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

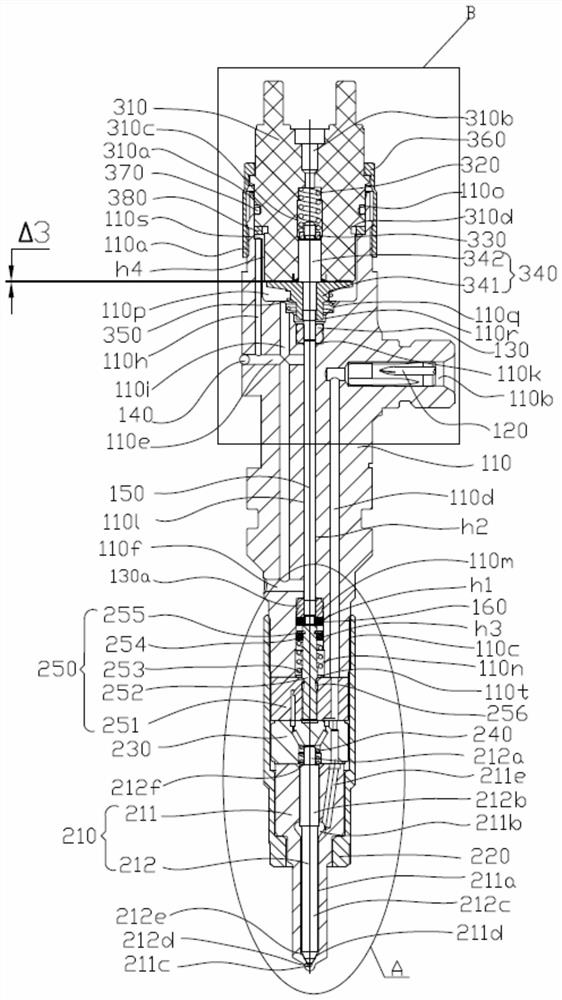

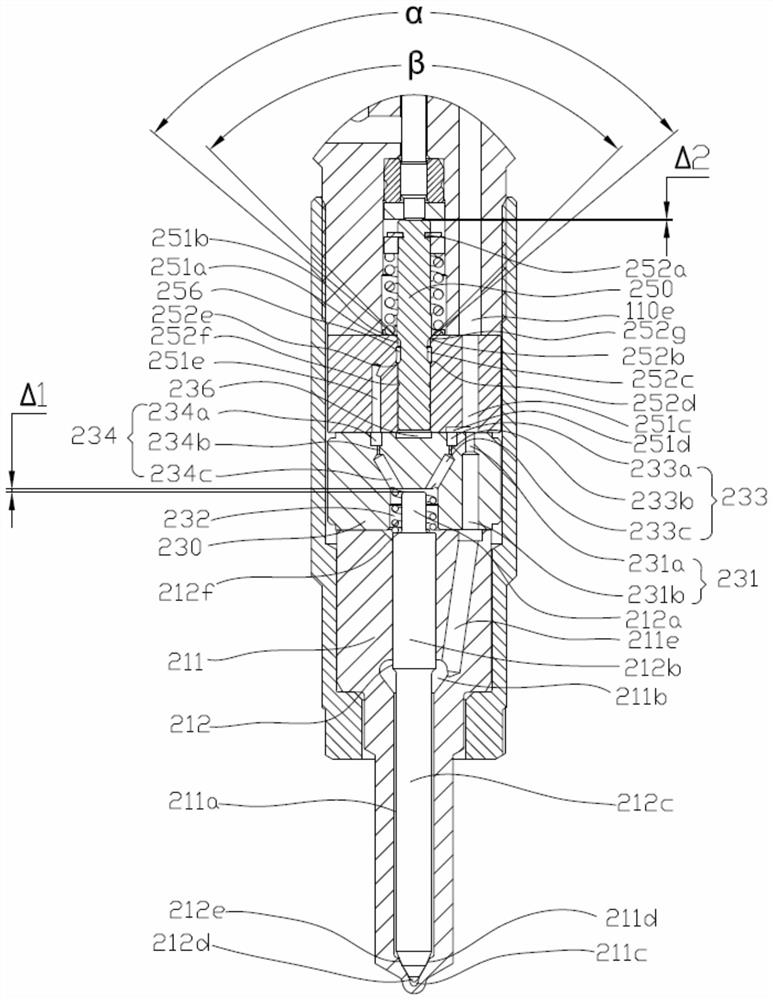

[0046] see figure 1 , figure 2 and Figure 4 , a high-pressure fuel injector used in a high-pressure common rail fuel injection system shown in the figure is assembled from injector body parts, fuel injection nozzle parts, and electromagnet parts. The specific structure is as follows:

[0047] The fuel injector body component 100 includes a fuel injector body 110 , a slit filter element 120 , an upper insert 130 , a steel ball 140 , a push rod 150 , an adjustment pad 160 , and a lower insert 130 a.

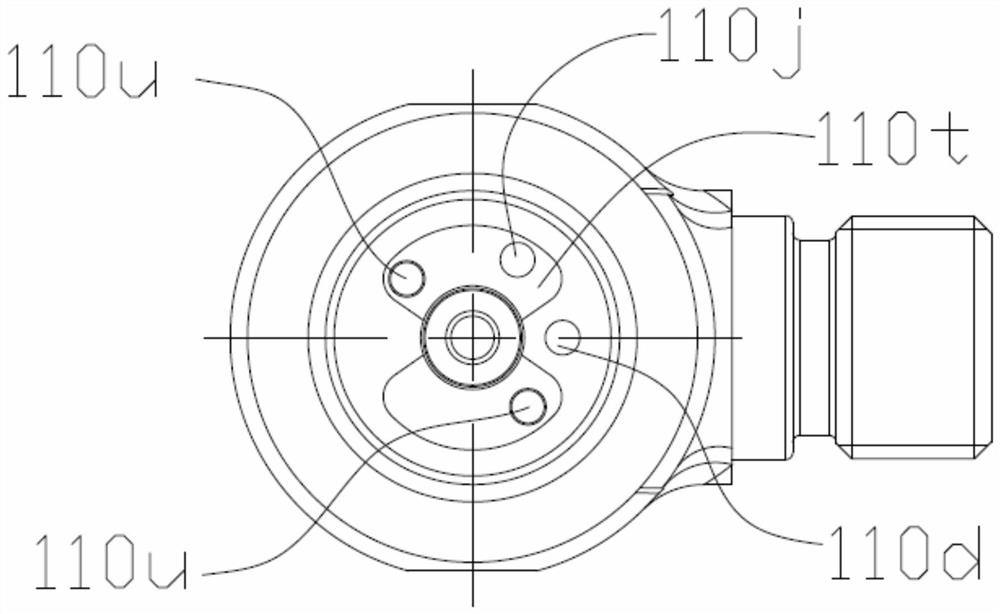

[0048] The injector body 110 is provided with an upper external thread 110a, an oil inlet hole 110b, and a lower external thread 110c. The oil hole 110b is disposed in the middle of the injector body 110 .

[0049] In the injector body 110, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com