Continuous casting method for steel

A slab and cooling zone technology, applied in the field of continuous casting of steel, can solve problems such as surface cracking, and achieve the effects of suppressing slab surface cracking, surface cracking, and water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

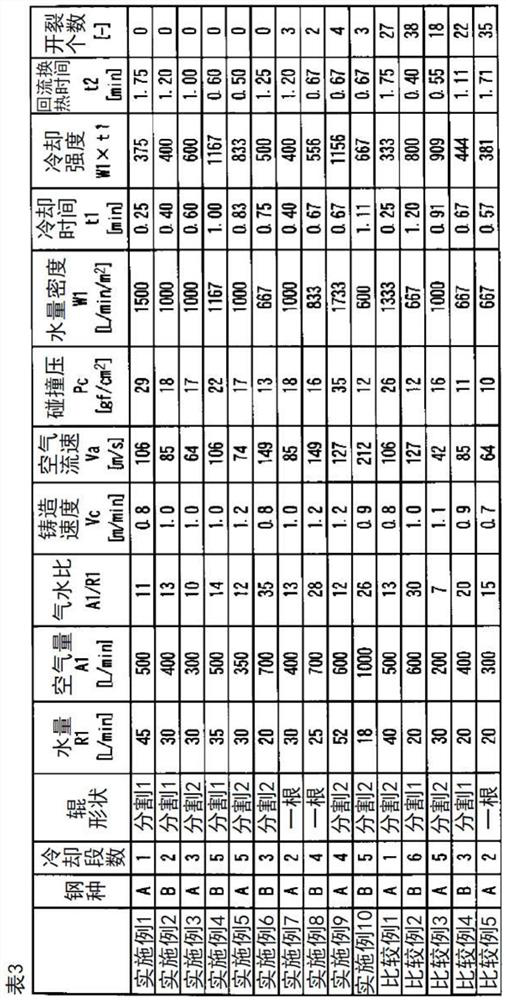

[0064] Hereinafter, examples are shown, and the continuous casting method of steel according to the present invention will be described in more detail.

[0065] 1. Experimental conditions

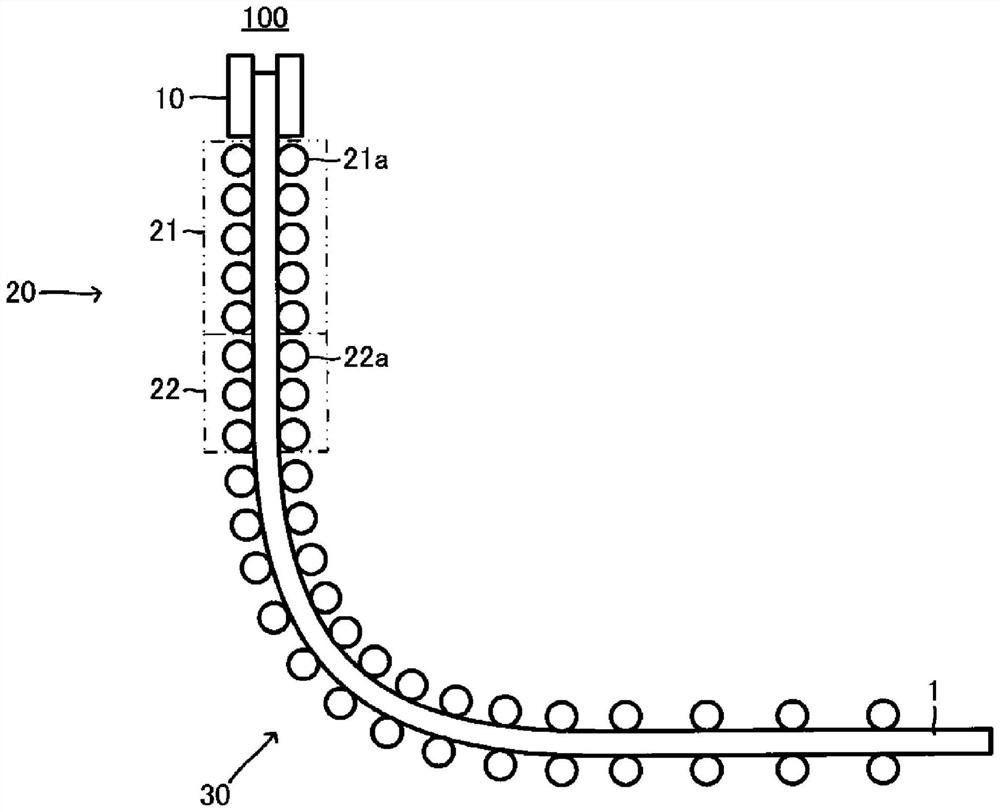

[0066] A slab with a width of 2200 mm and a thickness of 300 mm was produced using a vertical bending type continuous casting apparatus. The steel type was set to be a low-alloy steel having a composition (mass %) shown in Table 1 and having a high cracking sensitivity.

[0067] It should be noted that the Ac of steel types A and B 3 The point temperatures were 898°C and 872°C, respectively.

[0068] Table 1

[0069] C Si mn P S Cu Ni Cr Al Nb Ti N A 0.06 0.5 1.6 0.01 0.004 0.25 0.35 0.02 0.02 0.015 0.001 0.004 B 0.12 0.2 1.2 0.008 0.003 0.30 0.08 0.3 0.03 0.015 0.015 0.004

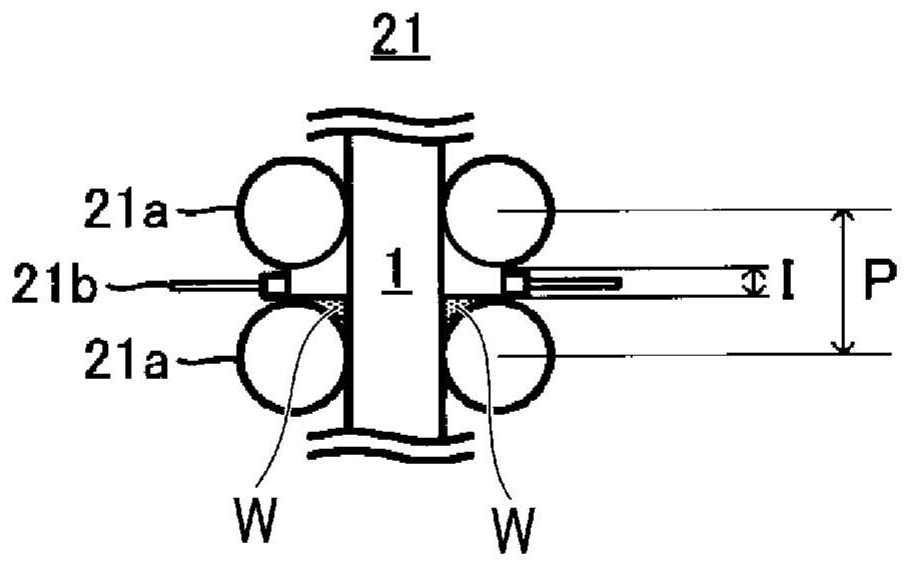

[0070] In the secondary cooling zone of the continuous casting device, 15 spray nozzles are installed at intervals of 150 mm in the width direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com