A compact multi-stage small rod continuous casting crystallizer system

A continuous casting crystallizer and crystallizer technology, applied in the field of continuous casting of small cast rods, can solve problems such as uneven cooling, aggravated grain size of the cast rod structure, insufficient cooling intensity, etc., to reduce breakage or liquid leakage accidents, Enhance the effect of uniform secondary cooling and avoid burning defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

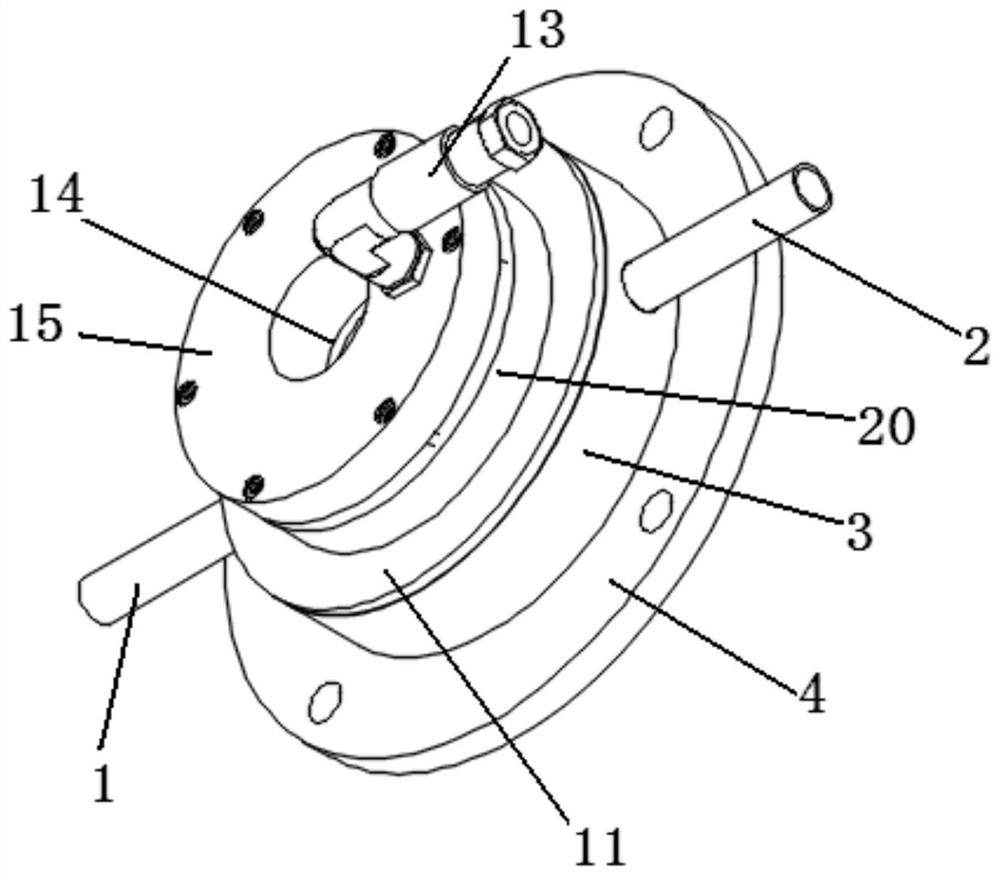

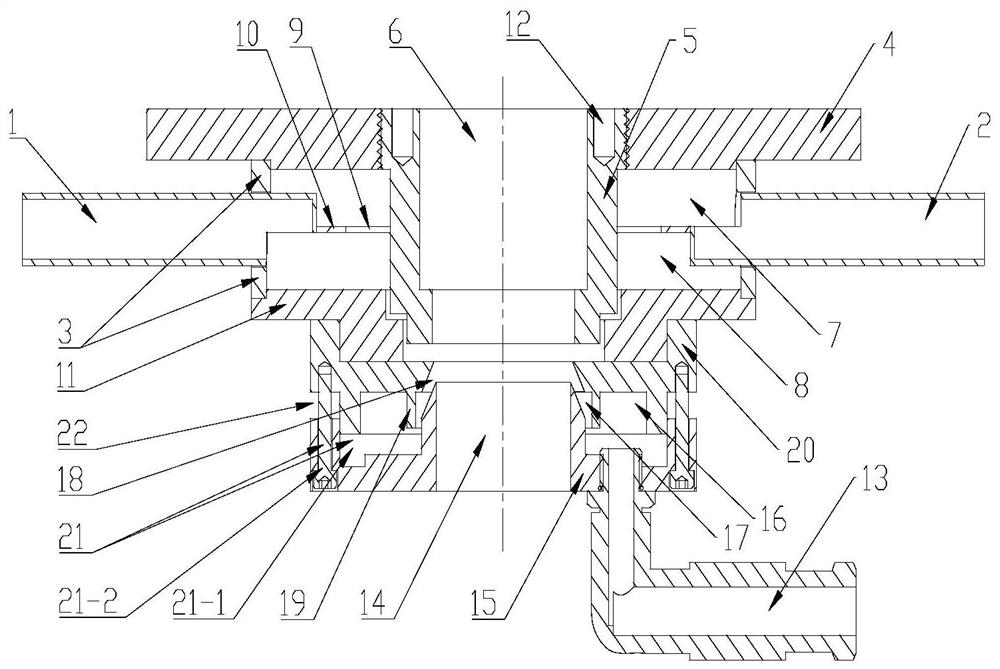

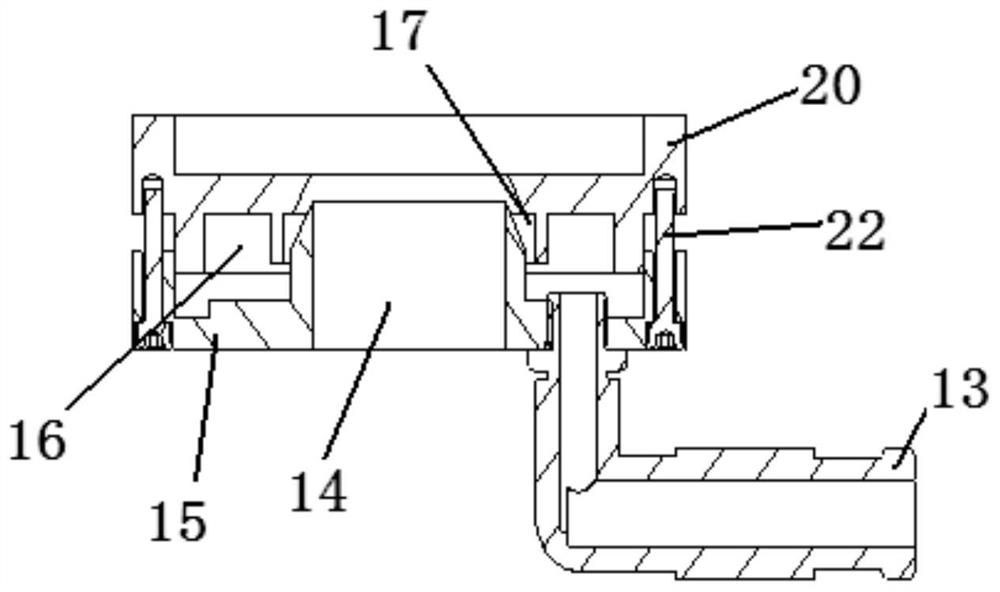

[0057] like figure 1 As shown, a compact multi-stage small rod continuous casting crystallizer system, figure 2 for figure 1 The cross-sectional schematic diagram of the multi-stage small casting rod continuous casting crystallizer system includes an annular flange plate 4, an annular bottom plate 11, an annular first shell 3, an annular first inner sleeve 5, a graphite mold 6, and an annular partition Plate 10, first water inlet 1, first water outlet 2, bolts 12 and other components. The annular flange plate 4 is welded to the upper end of the annular first shell 3 to keep the central axis coincident; the annular flange plate 4 fixes the continuous casting crystallizer system to the lower end of the induction heating furnace through bolt connection; the graphite mold 6 The lower part is installed in the annular first inner sleeve 5, the upper half of the graphite casting mold 6 is installed at the lower end of the induction heating furnace, and the annular first inner slee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com