Vacuum melting and casting device

A vacuum melting and melting furnace technology, applied in lighting and heating equipment, furnace components, furnaces, etc., can solve the problem that the magnetic properties of sintered magnets cannot be obtained, and achieve the effect of changing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the vacuum melting casting apparatus of the present invention will be described below with reference to the drawings. Hereinafter, terms indicating directions such as up, down, left, and right are preceded by figure 1 as the benchmark.

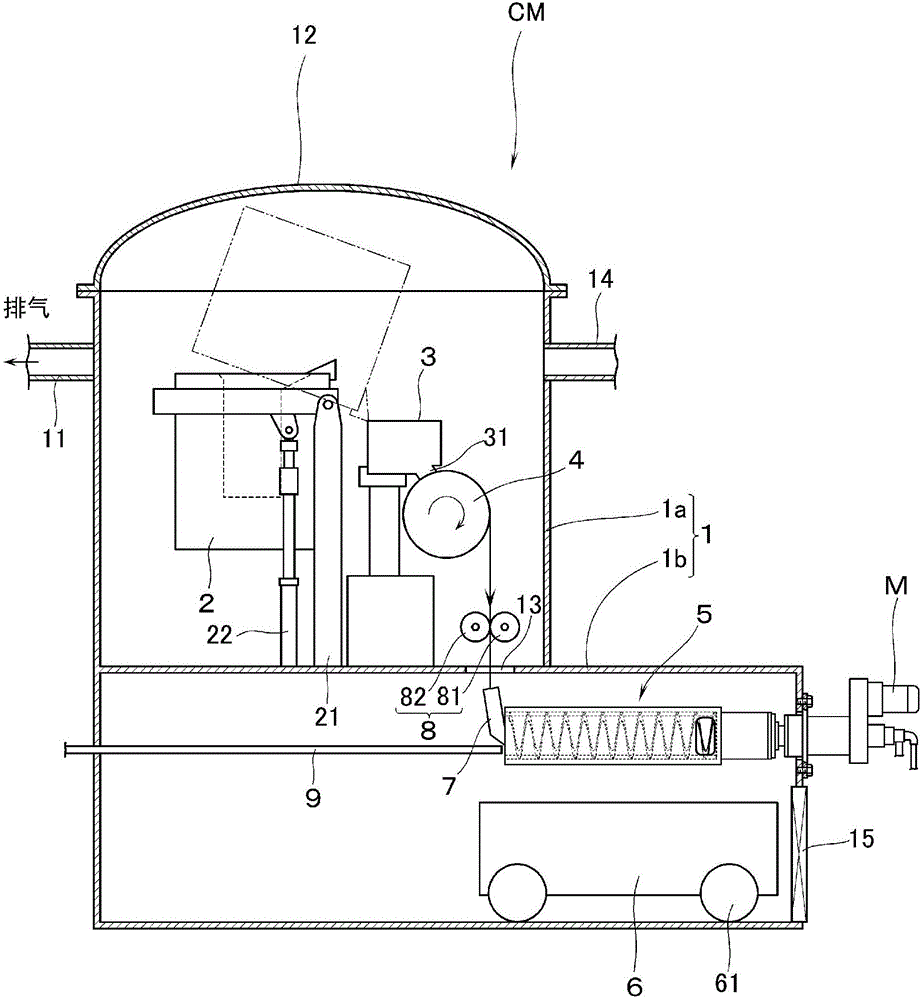

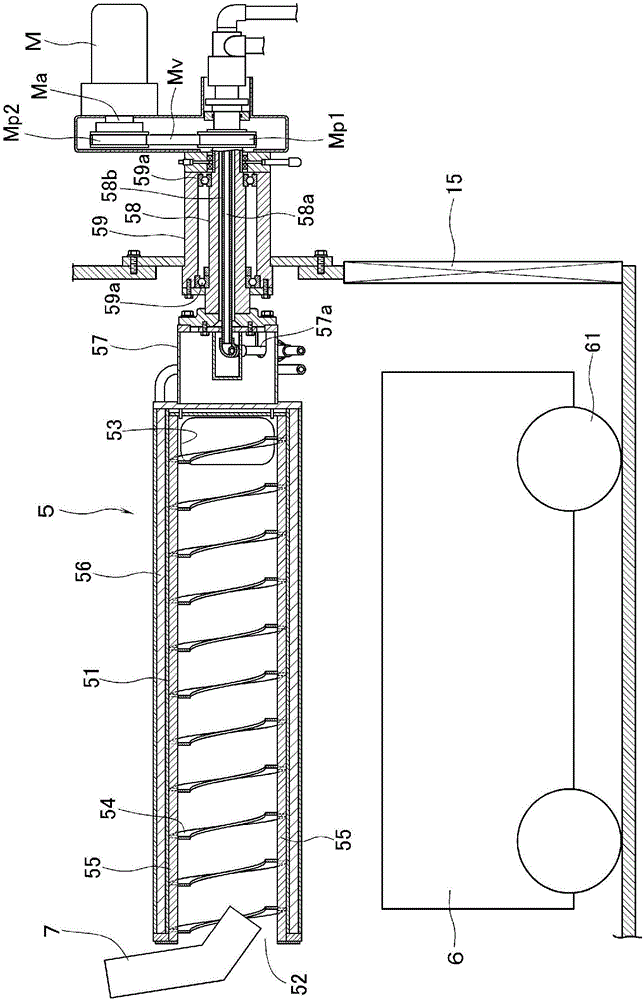

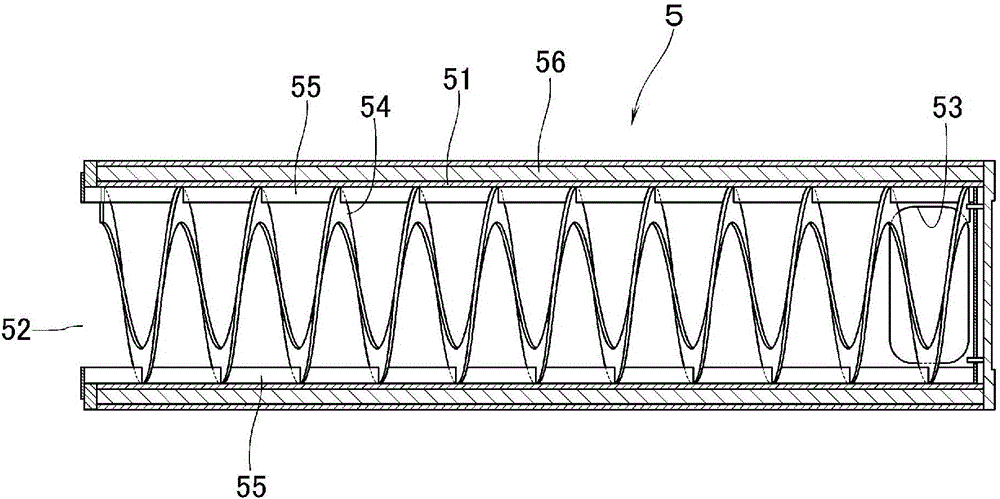

[0021] refer to figure 1 , CM is a vacuum melting casting device according to an embodiment of the present invention, and the vacuum melting casting device CM includes a closed container (vacuum chamber) 1 connected with a vacuum exhaust pipe 11 from a vacuum pump outside the figure. The airtight container 1 is composed of a vertical cylindrical main container part 1a and a horizontal cylindrical sub-tank part 1b connected to the lower part of the main container part 1a. An openable and closable lid 12 is provided on the upper end of the main container portion 1a. In addition, the melting furnace 2, the tundish 3, and the cooling roll 4 are accommodated in the main container part 1a, and the cooling drum 5 and the reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com