Reed cutting device

A cutting device and a technology for reeds, which are applied in the mechanical processing of plant materials, solid separation, classification, etc., can solve problems such as troublesome, inability to ensure that the reeds are placed in the same direction, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

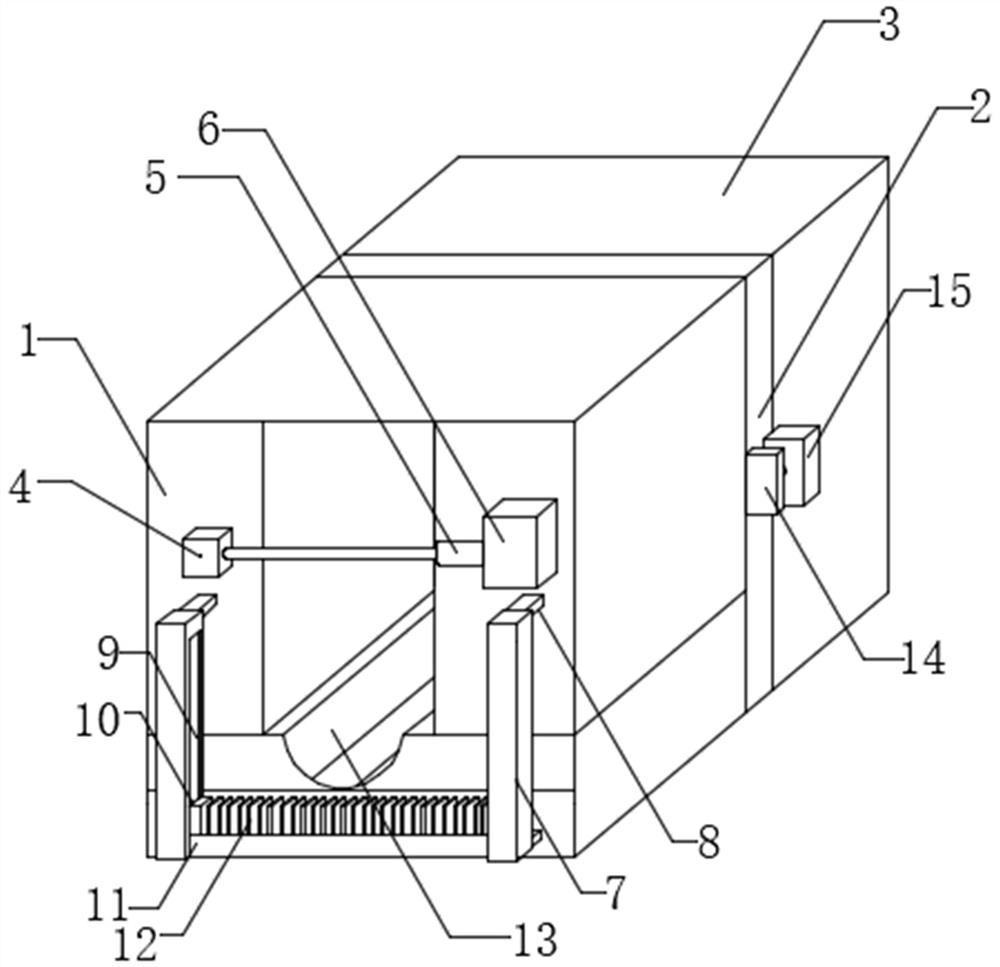

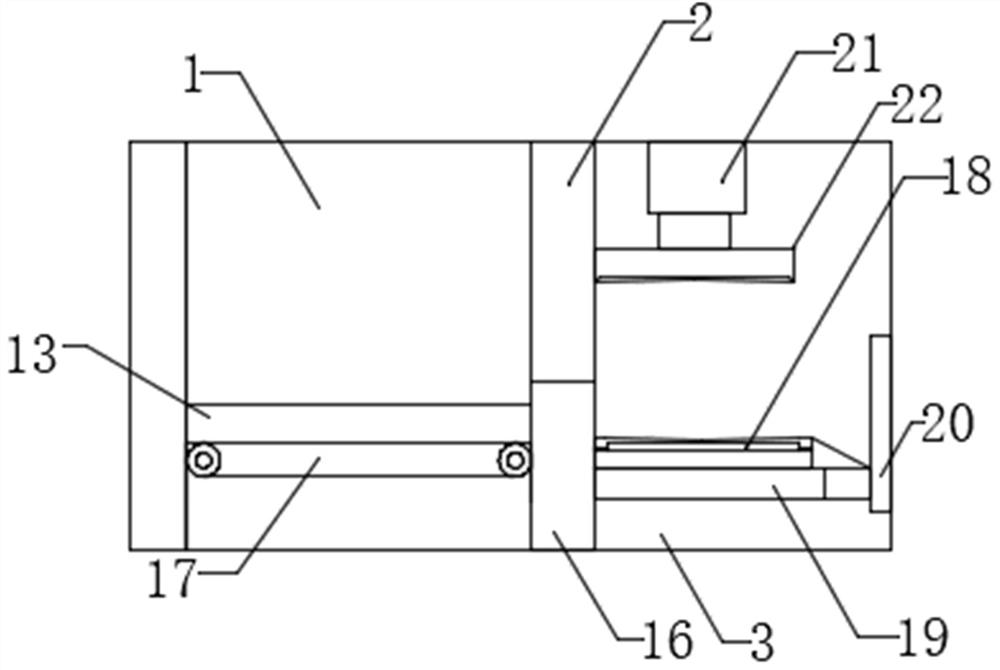

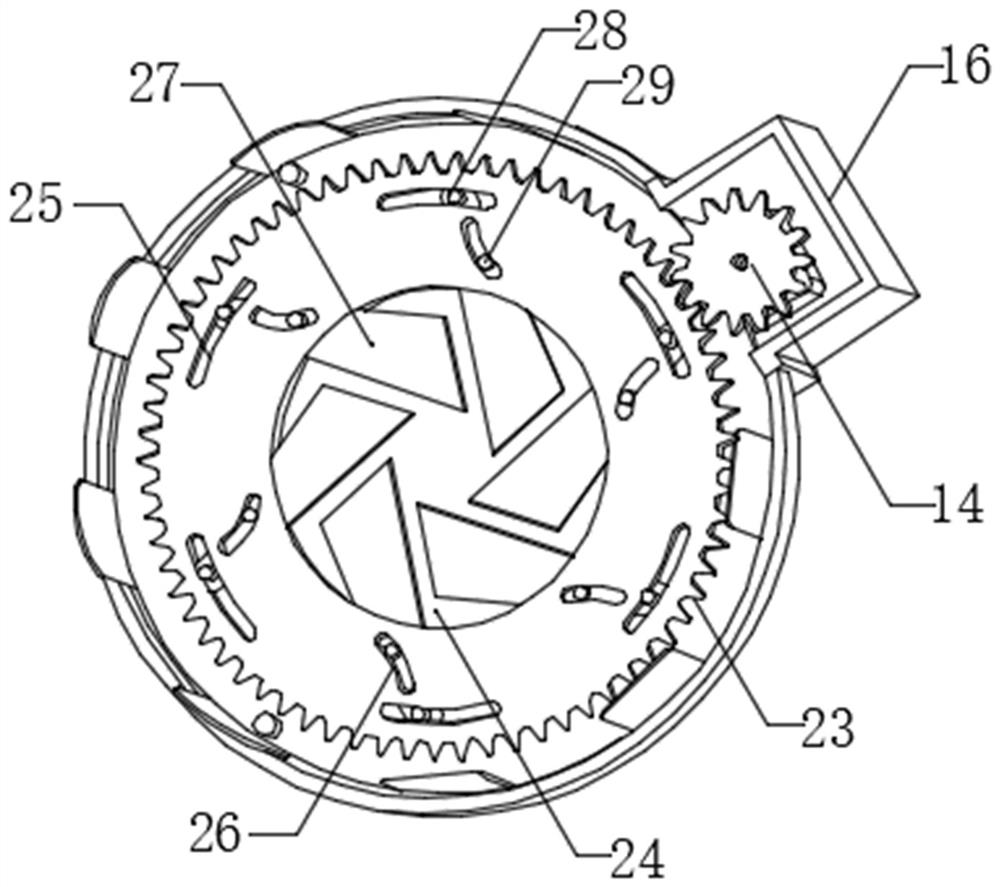

[0025] like Figure 1-5 As shown, a reed cutting device includes a sorting box (1) and a cutting plate (2), the bottom of the cutting plate (2) is equipped with a cutting piece (16), and one side of the cutting plate (2) A rotating motor (15) is installed, and one side of the cutting blade (16) is provided with a transfer gear (14), and the middle part of the transferring gear (14) is connected with the transmission rod of the rotating motor (15), and the surface of the cutting blade (16) is installed There is an outer ring gear (23), the inner layer of the outer ring gear (23) is hollow, the outer ring gear (23) and the intermediate gear (14) are meshed with each other, and the surface of the outer ring gear (23) is provided with several first arc-shaped limiters. Position groove (25), the surface of the outer ring gear (23) is also provided with a number of second arc-shaped limiting grooves (26) with the same number as the second arc-shaped limiting groove (26), the outer r...

Embodiment 2

[0032] like Figure 1-5 As shown, a reed cutting device includes a sorting box (1) and a cutting plate (2), the bottom of the cutting plate (2) is equipped with a cutting piece (16), and one side of the cutting plate (2) A rotating motor (15) is installed, and one side of the cutting blade (16) is provided with a transfer gear (14), and the middle part of the transferring gear (14) is connected with the transmission rod of the rotating motor (15), and the surface of the cutting blade (16) is installed There is an outer ring gear (23), the inner layer of the outer ring gear (23) is hollow, the outer ring gear (23) and the intermediate gear (14) are meshed with each other, and the surface of the outer ring gear (23) is provided with several first arc-shaped limiters. Position groove (25), the surface of the outer ring gear (23) is also provided with a number of second arc-shaped limiting grooves (26) with the same number as the second arc-shaped limiting groove (26), the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com