Fine adjustment winder assembly of lifting screen

A wire reel and screen technology, applied in the direction of screens, furniture parts, tables, etc., can solve problems such as difficult to achieve, different lengths, and changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

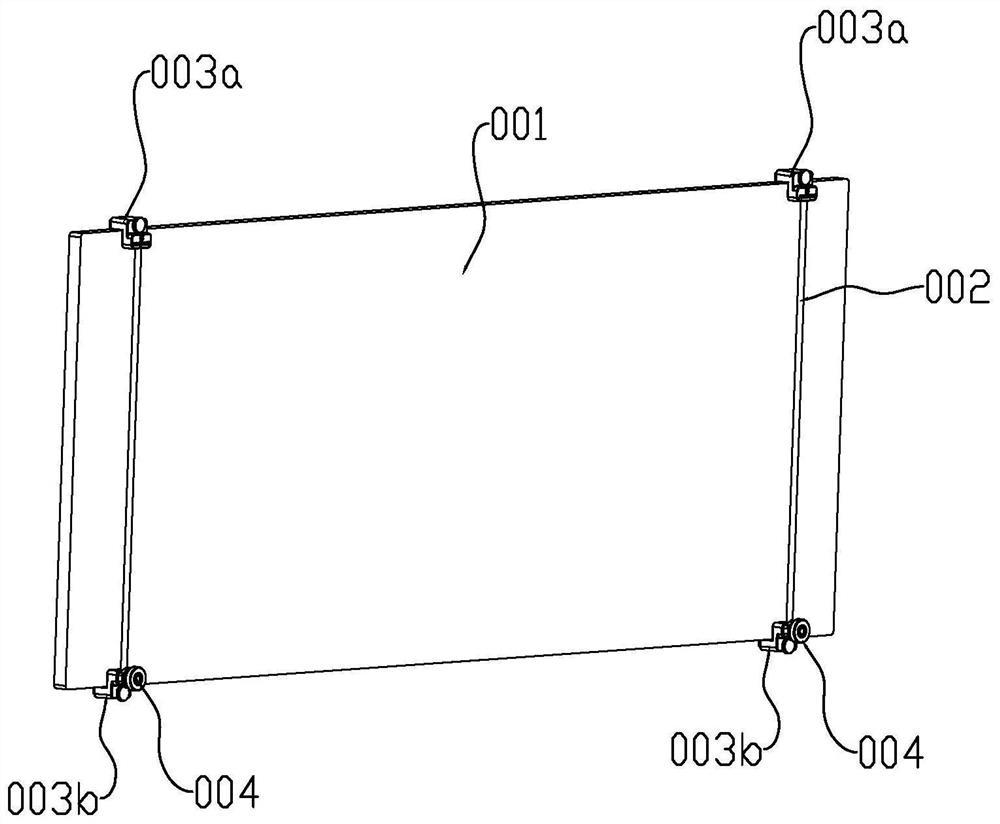

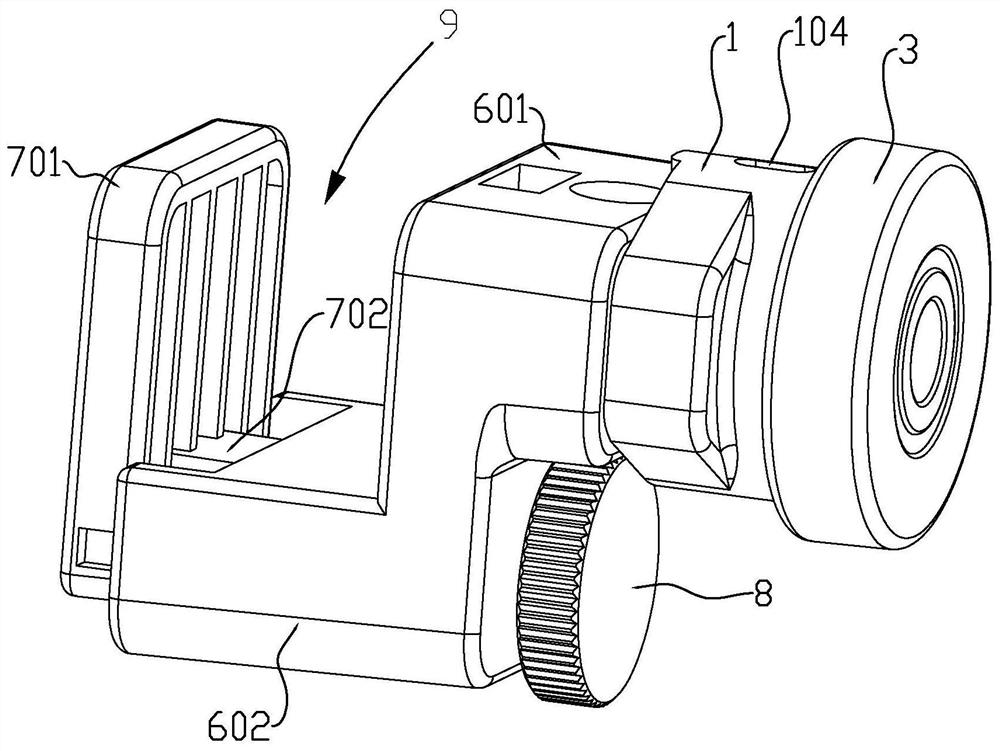

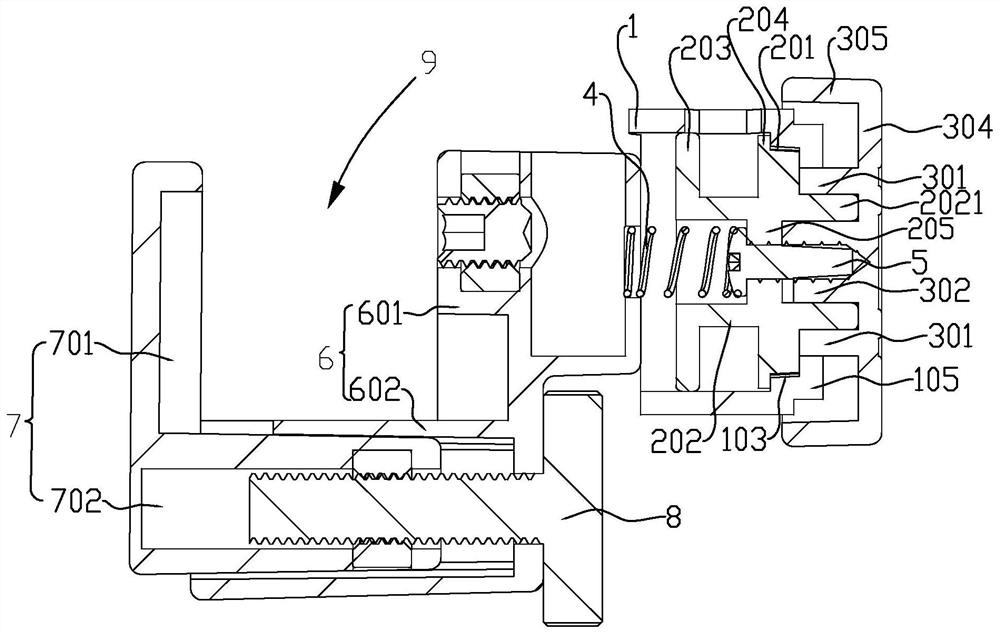

[0034] Such as Figure 1 to Figure 8 As shown, the lifting screen 001 fine-tunes the wire reel assembly, including the screen fixing seat and the self-locking wire reel 004, and the self-locking wire reel 004 includes the wire reel base 1, the wire reel 2 and the driving part, and the screen is fixed The seat is installed on the lifting screen 001, the wire reel base 1 is fixed on the screen fixing seat, the wire reel 2 is fixedly connected with the driving part, and the driving part drives the wire reel 2 to move axially relative to the wire reel base 1 and / or Or rotate, there is a self-locking mechanism between the cord reel base 1 and the cord reel 2, the cord reel 2 moves axially relative to the cord reel base 1 to self-lock or unlock, and the screen fixing seat is provided with a width adjustable Adjusted slot 9, the lower edge of the lifting screen 001 is inserted in the slot 9.

[0035]The self-locking wire reel 004 in this embodiment is installed on both sides of the ...

Embodiment 2

[0059] The difference between this embodiment and the first embodiment is that the self-locking mechanism is closer to the lifting screen 001 than the driving part, and in the winding mode, the driving part pulls the winding wheel 2 to move outward and unlock.

[0060] At this time, the compression spring or shrapnel used as the elastic reset member 4 should be arranged between the cord reel 2 and the cord reel base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com