Label film and production method thereof

A production method and label technology, applied in the field of packaging labels, can solve the problems of low recyclability of raw materials, difficult recycling of labels, huge demand, etc., and achieve better overall aesthetics, high gloss, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

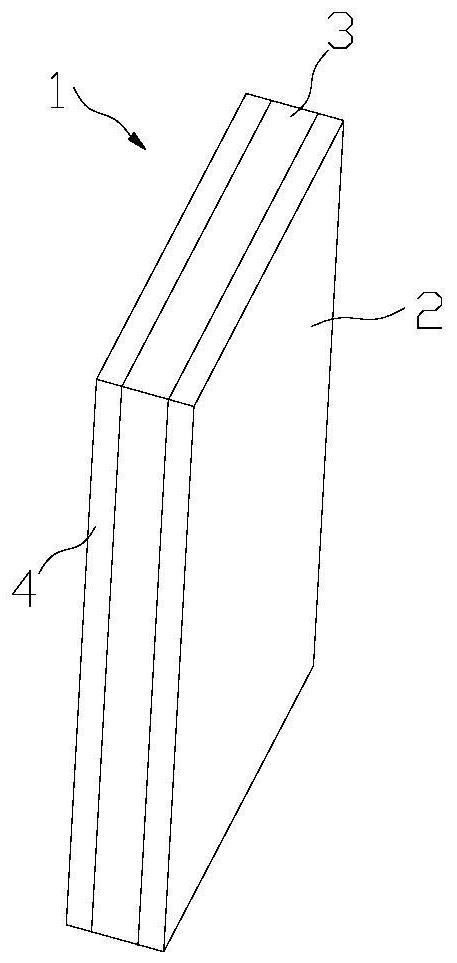

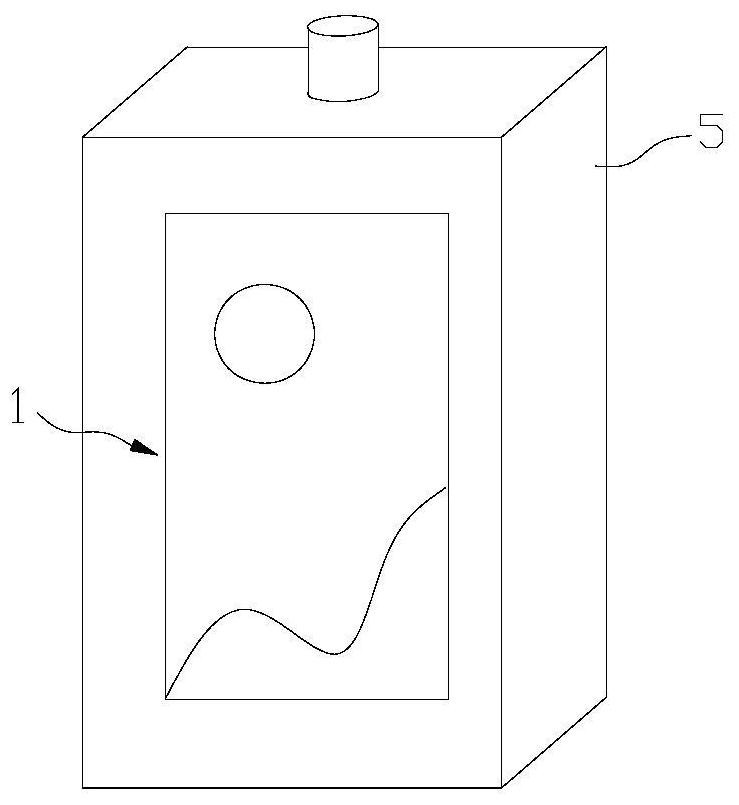

[0041] see Figure 1 to Figure 3 , a label film 1 of the present embodiment, comprising a superimposed outer layer 2, a middle layer 3 and an inner layer 4, the outside of the outer layer 2 can be used for printing ink, and the inner layer 4 can be used with a release paper package The outer surface of 5 is bonded; the outer layer 2, the middle layer 3 and the inner layer 4 respectively include at least two materials among HDPE, MDPE, LDPE and mPE; the thickness of the label film 1 is 10-100 μm.

[0042] The thickness ratio of the outer layer 2, the middle layer 3 and the inner layer 4 is: 1-5:2-10:1-5.

[0043] The components of the outer layer 2 include at least HDPE and LDPE, the weight percentage of HDPE is 10-20%, and the weight percentage of LDPE is 10-80%; the components of the middle layer 3 include at least HDPE and LDPE, HDPE The weight percentage of LDPE is 10-50%, and the weight percentage of LDPE is 10-50%; The components of the inner layer 4 include at least HDP...

Embodiment 2

[0059] Another object of the present invention is to provide a method for using the label film of the first embodiment, comprising the following steps:

[0060] (1) Retrieval: roll up part of the label film;

[0061] (2) Printing: graphic printing on the outer surface of the label film;

[0062] (3) Cutting: use a mold to die-cut the label film to obtain a roll label containing several labels;

[0063] (4) Labeling: Put the roll label into the labeling machine, cut off a single label on the roll label and coat the inner layer with adhesive to adhere to the outer surface of the package.

[0064] Compared with the prior art, in the method of using a label film of the present invention, the label adopted is easy to print and cut, and has a soft texture, and the label film has good compatibility with adhesives and PE packaging materials. A small amount of adhesive can be closely attached to PE packaging materials, saving the use of adhesives, thereby increasing the labeling spee...

Embodiment 3

[0066] Another object of the present invention is to provide the production method of the label film of the first embodiment above.

[0067] The production method is applied to co-extrusion equipment. The co-extrusion equipment is provided with a feeding mechanism, an extrusion mechanism and a die head. There are three extrusion mechanisms. A filtering device is arranged in the extrusion port of the extrusion mechanism. The extrusion Both the mechanism and the die are equipped with 7 heating zones.

[0068] The three extrusion mechanisms are extrusion mechanism A, extrusion mechanism B and extrusion mechanism C, wherein extrusion mechanism A is used to output the molten inner layer material, and extrusion mechanism B is used to output the molten middle layer material. Mechanism C is used to output the molten outer layer material.

[0069] Described production method comprises the following steps:

[0070] (1) Outer layer materials, middle layer materials and inner layer mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap