Concrete grouting device for building construction

A building construction and concrete technology, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of slowing down the concrete grouting speed and sand clusters stuck inside the feeding pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

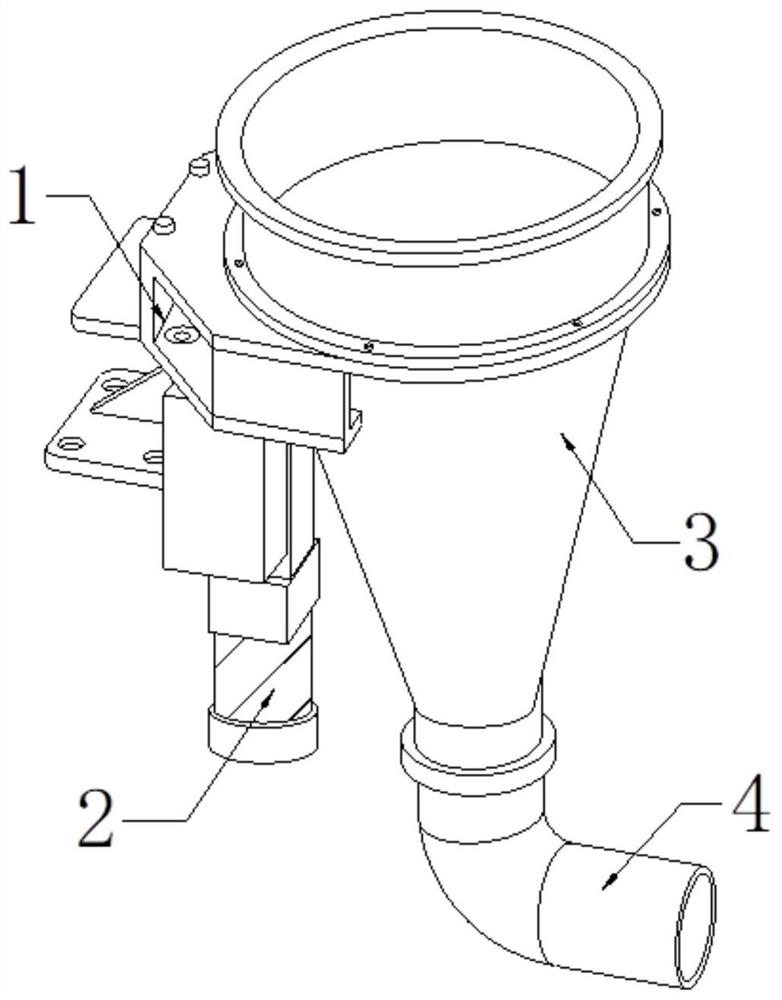

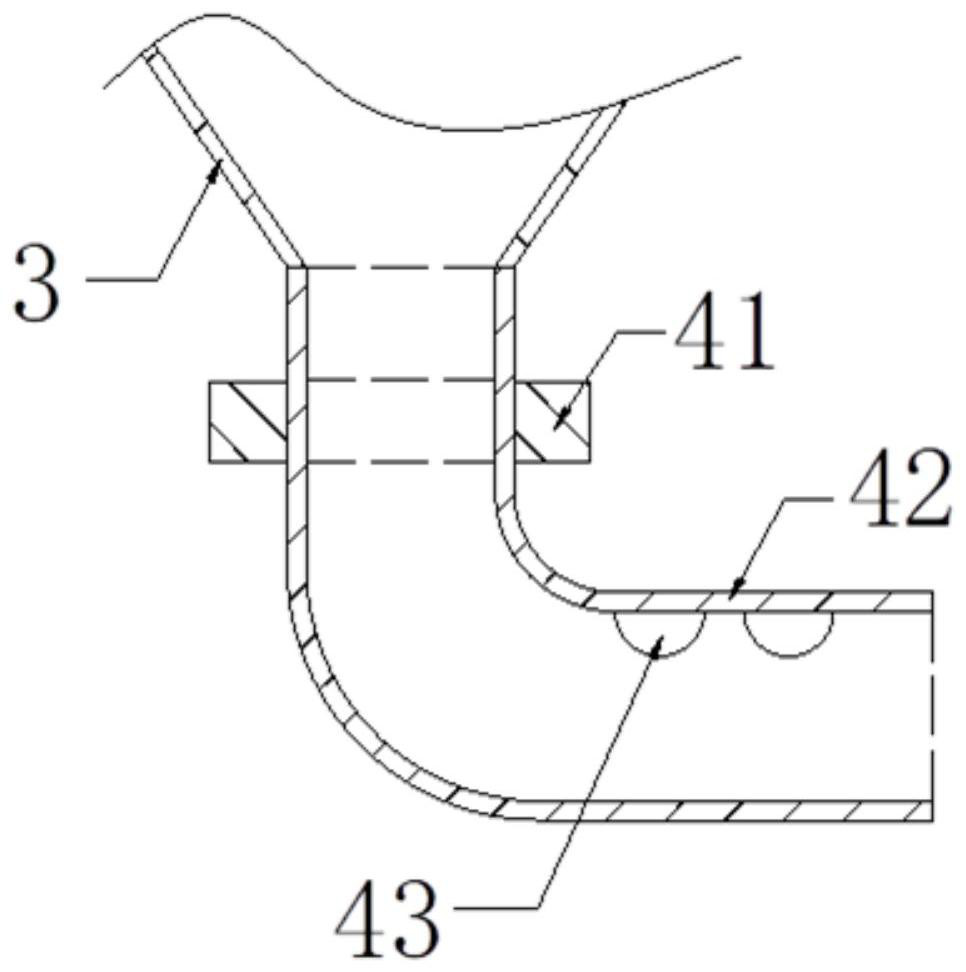

[0029] Such as Figure 1 to Figure 5 Shown: the present invention provides a kind of concrete grouting device for building construction, and its structure comprises fixed block 1, vibrator 2, hopper 3, feeding pipe 4, and described vibrator 2 top is connected with fixed block 1 bottom surface by bolt, so The left side of the hopper 3 is welded to the right end surface of the fixed block 1, and the top of the feeding pipe 4 is connected to the bottom of the hopper 3 . Such as figure 2 As shown, the feeding pipe 4 includes a connection block 41, a pipe body 42, and a dispersing mechanism 43. The pipe body 42 is nested in the middle of the connection block 41 near the top end, and the top of the dispersing mechanism 43 is installed on the pipe body 42 near the top. At the inner top position of the right end, the top of the pipe body 42 communicates with the bottom of the hopper 3 .

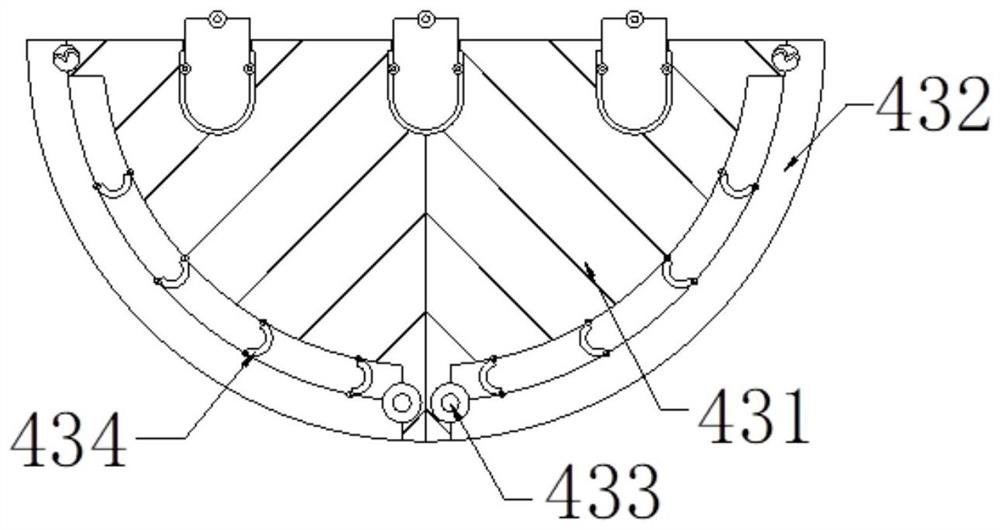

[0030] Such as image 3 As shown, the dispersing mechanism 43 includes a support block 431, t...

Embodiment 2

[0036] Such as Image 6 As shown, the support block 431 includes an engaging block 31a, three engaging grooves 31b, three engaging rods 31c, an inner groove 31d, and a sliding ball 31e, each engaging groove 31b is recessed on the top surface of the engaging block 31a from top to bottom, each The bottom end of the connecting rod 31c is enclosed within a draw-in groove 31b, and an inner groove 31d is arranged at the inner bottom of the connecting block 31a. The sliding ball 31e is located inside the inner groove 31d and can slide. On the tube body 42. The support block 431 is suspended on the inner bottom of the pipe body 42 through the connecting rod 31c, which is beneficial for the supporting block 431 to swing left and right under the thrust of the material flow, which can push the material and accelerate the discharge speed of the material. There are three connecting rods 31c, It is beneficial to increase the support force received by the support block 431, reduce the pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com