Outer hoop locking type anti-warping brake disc

A brake disc, tight type technology, applied in the direction of brake disc, brake type, brake parts, etc., can solve the problem of increasing the difficulty and workload of brake disc installation, the inconvenient disassembly and assembly of bolt connection structure, and the reduction of effective area. Small problems, to achieve the effect of increasing heat dissipation, improving connection stability, and supporting a large contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

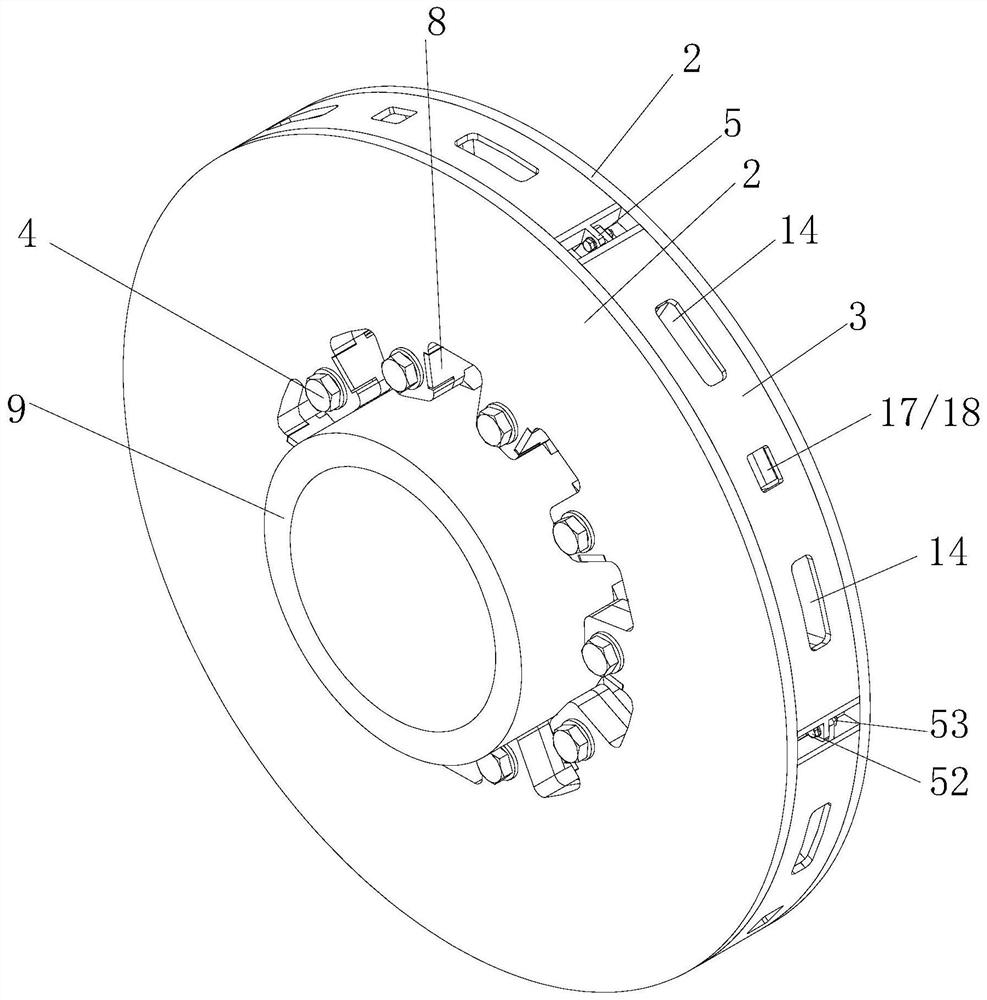

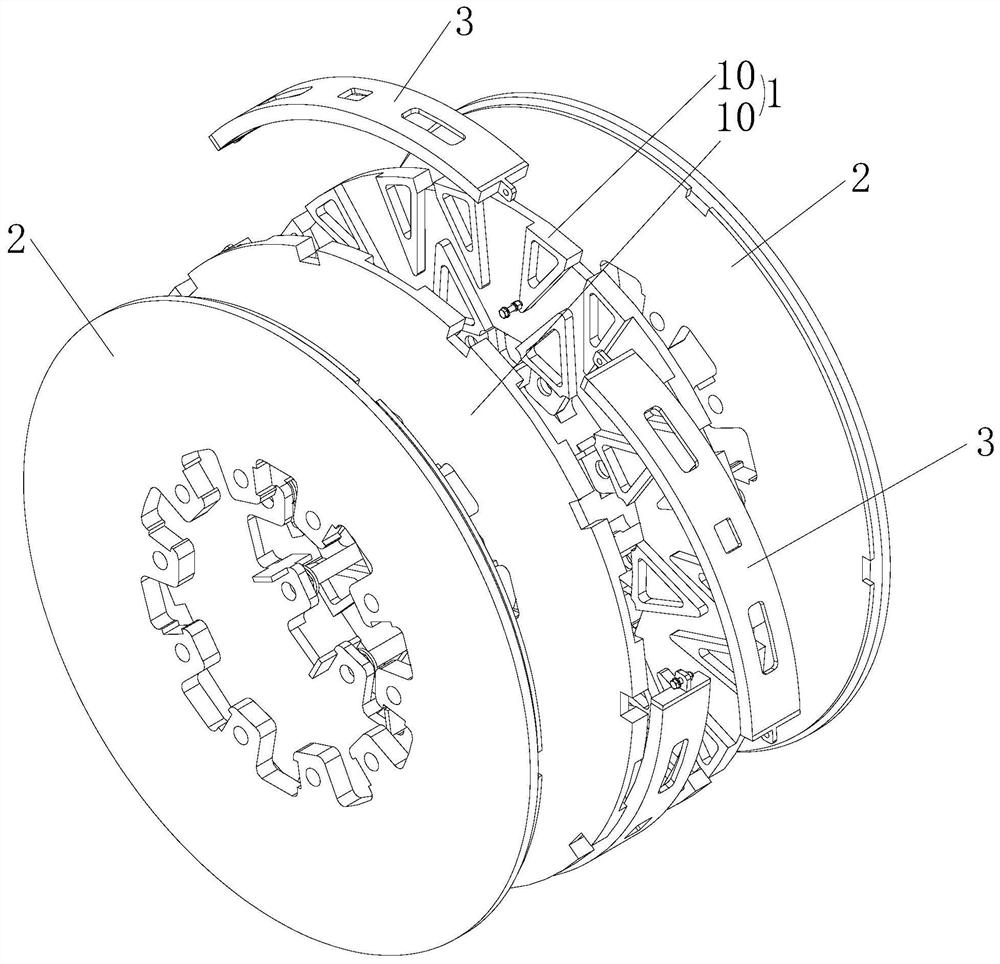

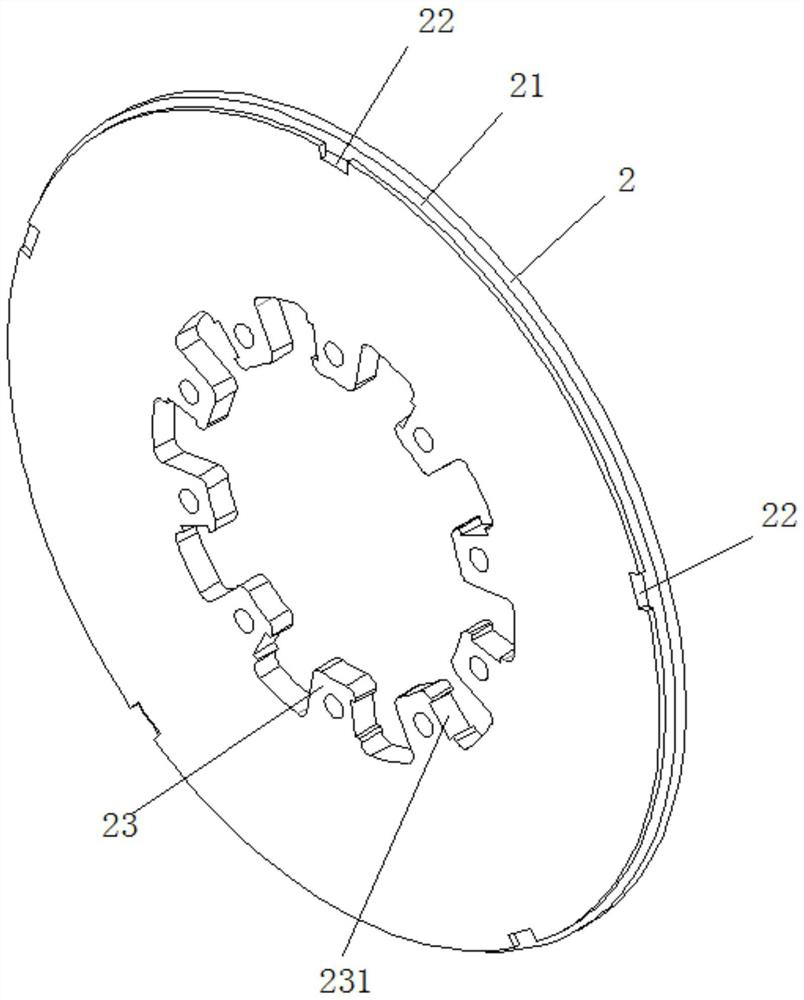

[0034] Such as Figure 1 to Figure 9 As shown, the outer hoop locking type anti-warping brake disc of this embodiment includes a support disc 1, an anti-warping outer hoop 3 and two friction discs 2, and the two friction discs 2 are attached to both sides of the support disc 1 respectively. , and the three are clamped and locked by fastening components. Both the support plate 1 and the friction plate 2 are provided with a central through hole, and the anti-warping outer hoop 3 is set on the outer periphery of the support plate 1. The anti-warping outer hoop 3 includes at least two arc outer hoop segments 31, and each arc outer hoop is divided into two parts. The pieces 31 are connected end to end, and the two sides of the arc outer hoop segment 31 are provided with anti-warping baffles 311, and the circumferential surface of the friction disc 2 is provided with anti-warping grooves 21, and the anti-warping baffles on both sides of the arc outer hoop segment 31 The plates 311 ...

Embodiment 2

[0052] Such as Figure 10 As shown, the outer hoop locking type anti-warping brake disc of this embodiment differs from Embodiment 1 only in that:

[0053] In this embodiment, the structure of the arc outer hoop segment 31 is different. Specifically, the two ends of the arc outer hoop segment 31 do not need to be provided with an installation end plate 314, the outer hoop boss 51 is arranged in an L shape, and the outer hoop boss 51 is directly fixed on the end of the arc outer hoop segment 31, In this way, the two outer hoop bosses 51 in the locking structure 5 overlap in the radial direction, the axis of the locking hole 511 is perpendicular to the axis of the brake disc, and a threaded hole or welding is made on the inner outer hoop boss 51 in the radial direction. The nut, the locking hole 511 on the radially outer outer hoop boss 51 is a through hole, which can be locked by the locking bolt 52 . This structure can be directly engaged in the anti-warping groove 21 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com