Method for solving environmental protection problem in wood transportation process

A transportation process and environmental protection technology, applied in transportation and packaging, devices to prevent multi-way movement of goods, dryers for static materials, etc., can solve the problems of large space occupation, environmental protection, long time, etc., to reduce resource consumption and carbon emissions, saving resources, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

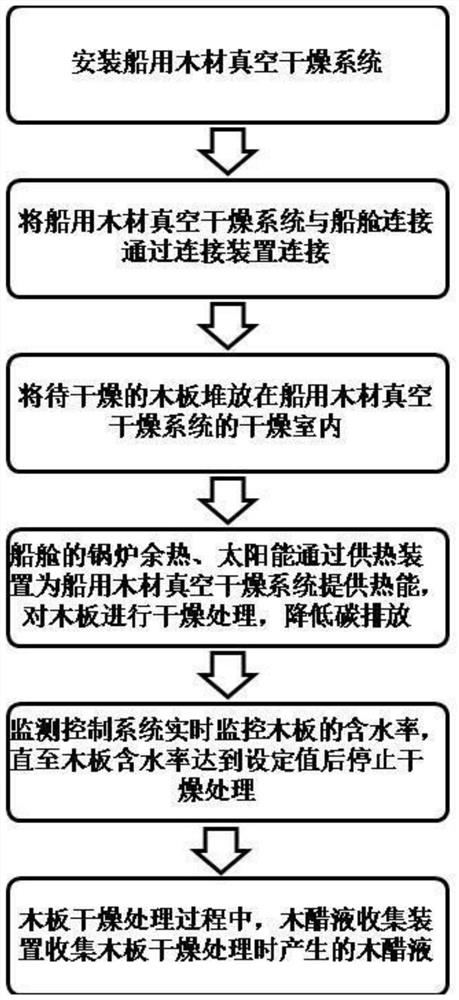

[0039] Such as figure 1 As shown, the present embodiment is a solution to the environmental protection problem in the timber transportation process, which specifically includes the following steps:

[0040] S1, installation of marine wood vacuum drying system;

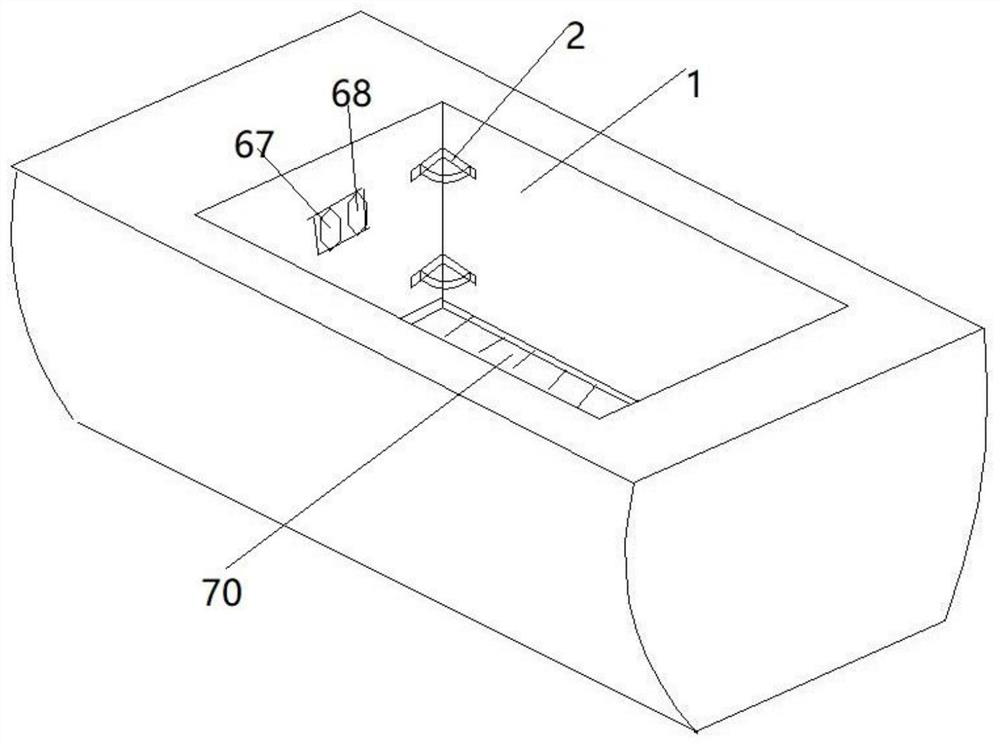

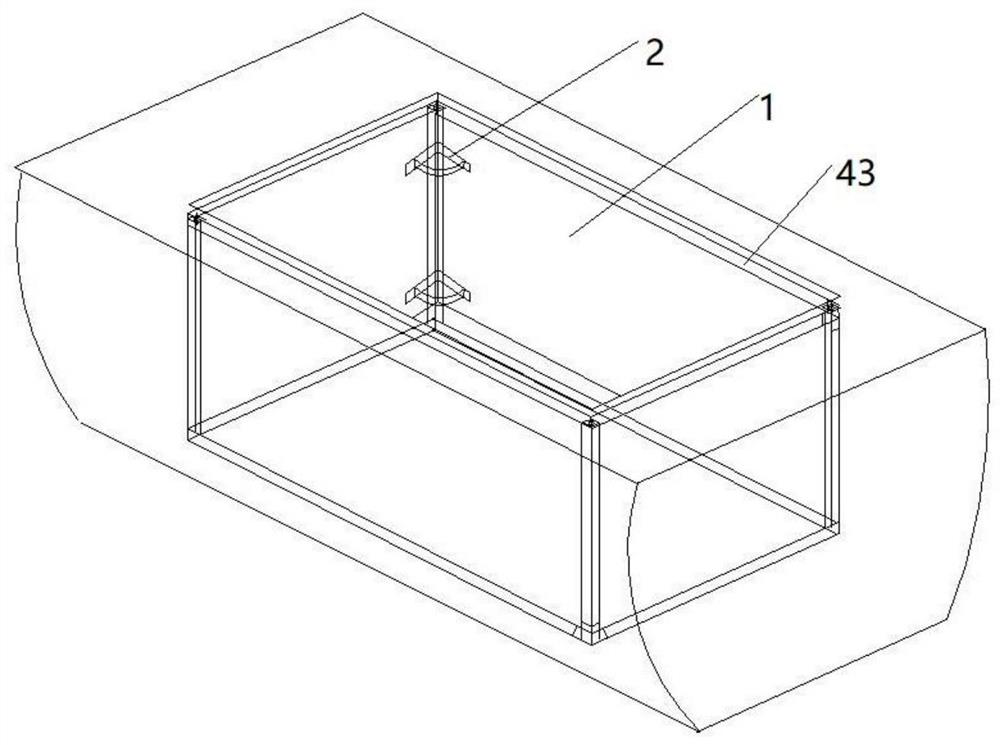

[0041] S2, connecting the marine wood vacuum drying system to the cabin through the connecting device 2;

[0042] S3, stacking the planks to be dried in the drying chamber 3 of the marine wood vacuum drying system;

[0043] S4, boiler waste heat and solar energy in the cabin 1 provide thermal energy for the marine wood vacuum drying system through the heating device 4, and dry the wood boards to reduce carbon emissions;

[0044] S5, the monitoring and control system monitors the moisture content of the plank in real time, and stops the drying process until the moisture content of the plank reaches the set value;

[0045] S6, during the wood board drying process, the wood vinegar collecting device 5 collects wood vin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap