A vibration damping pad noise test system

A test system and vibration damping pad technology, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as the same adjustment position, low data reliability, and the inability to meet the performance improvement requirements of vibration damping pads, etc., to achieve The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

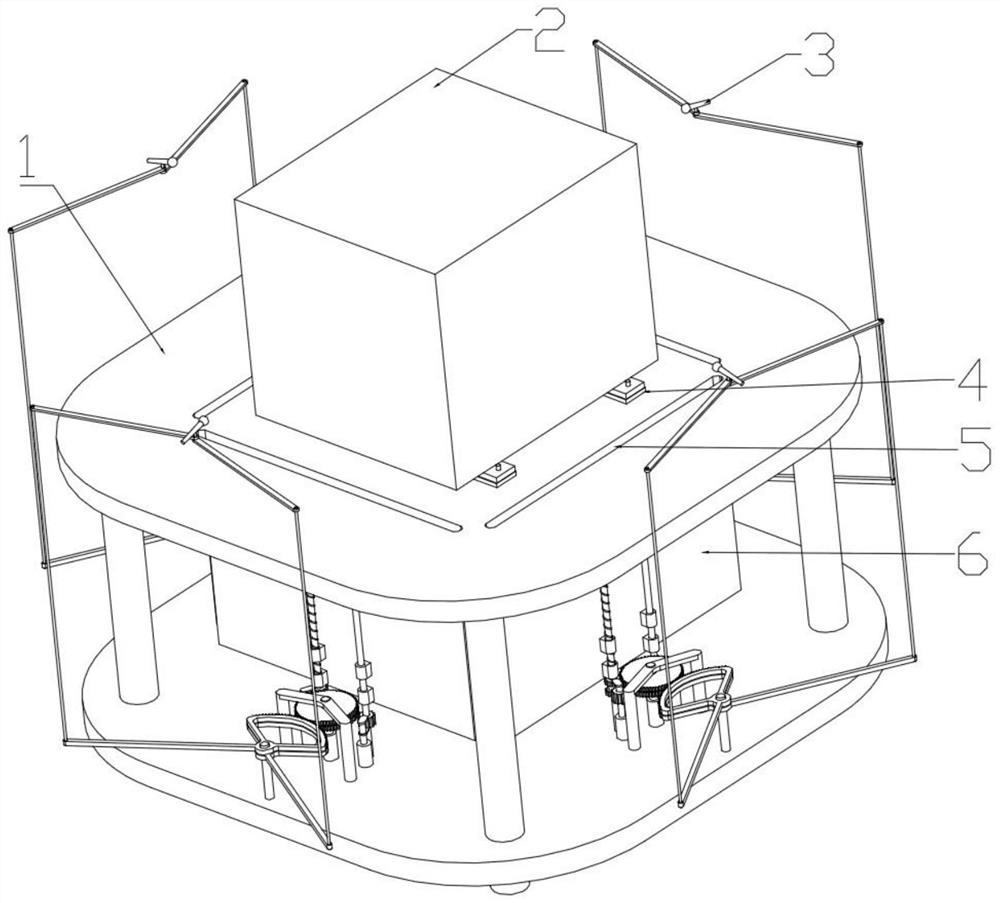

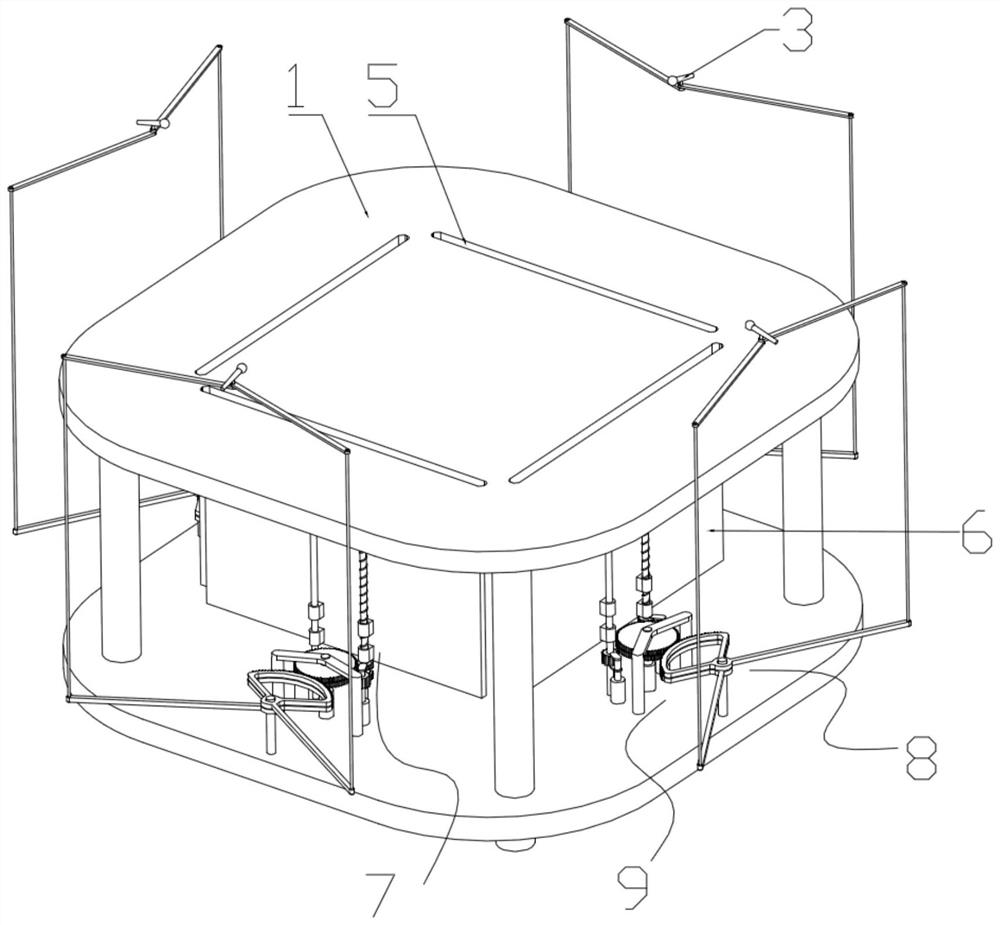

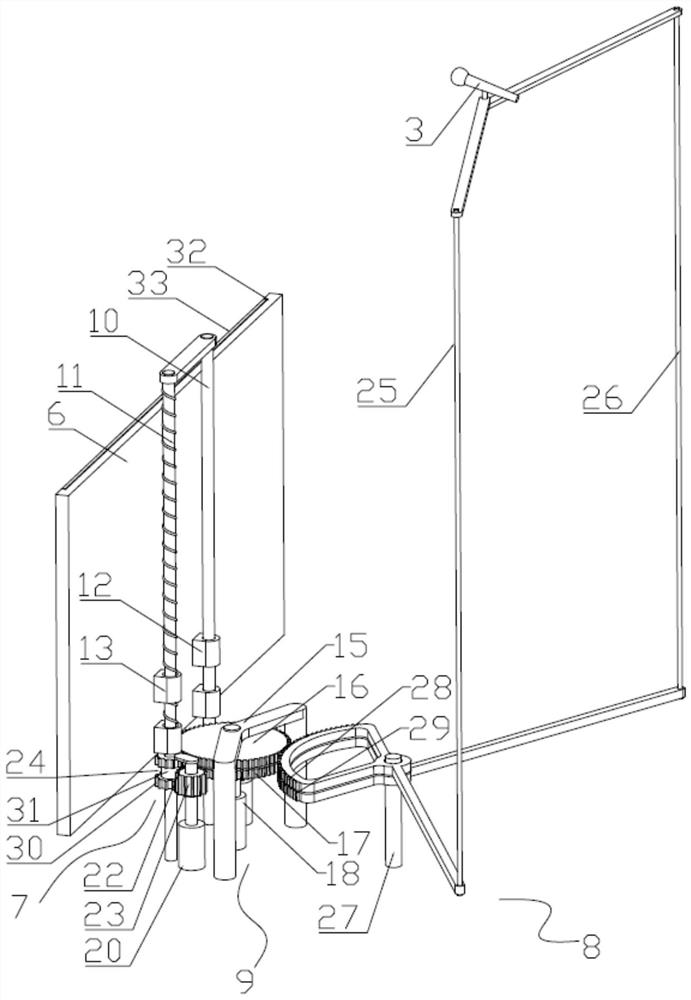

[0024] like Figure 1 to Figure 4 As shown, a vibration damping pad noise testing system includes a frame 1 placed in a semi-anechoic chamber, an air conditioner external unit 2 is placed on the frame 1, and microphones 3 are arranged around the air conditioner external unit 2, and the air conditioner The lower end of the leg of the external machine 2 is bolted to the damping pad 4, and the microphone 3 is electrically connected to the noise and vibration test and analysis system and provides the collected noise source for the noise and vibration test and analysis system, which is used for comparative analysis The data difference of the noise source of the air conditioner outdoor unit 2 in different environmental operation modes and before and after using the vibration damping pad 4 .

[0025] In this embodiment, the frame 1 is provided with four relief slots 5 with symmetrical structures arranged around the air conditioner external unit 2. A retractable baffle 6 is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com