Optical imaging system, image capturing module, electronic equipment and automobile

A technology of optical imaging system and optical axis, applied in optics, optical components, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

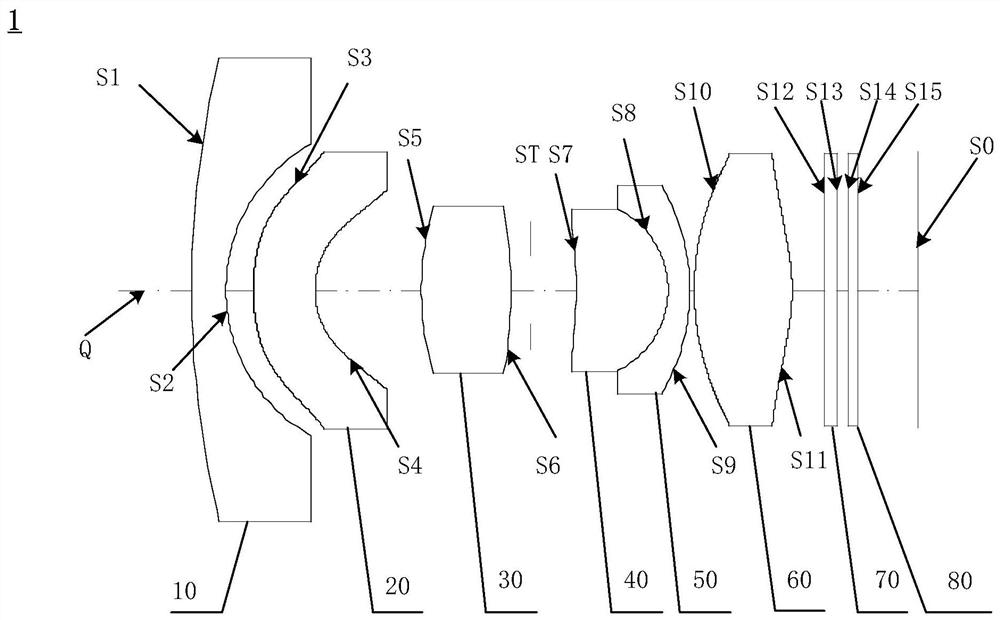

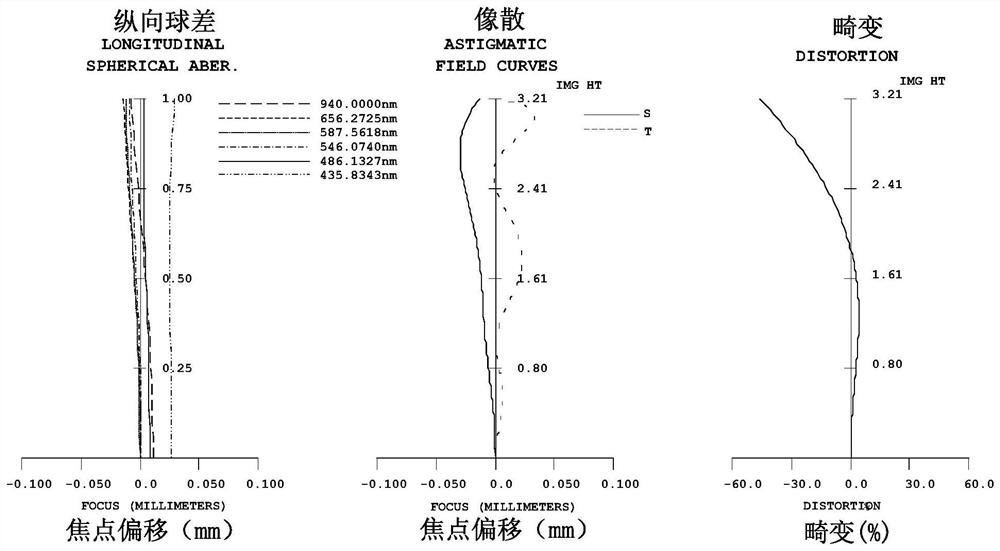

[0132] Refer figure 1 and figure 2 The optical imaging system 1 in the first embodiment includes a first lens 10 having a negative flexible force in the image side, a second lens 20 having a negative flexible force, a third lens 30 having a divergetic force. The fourth lens 40 having a divergetic force, a fifth lens 50 having a negative flexible force, a sixth lens 60, a filter 70, and a protective glass 80 having a positive flexible force.

[0133] Wherein, the side surface S1 of the first lens 10 is a convex surface at a proximal optical axis Q, and the image side surface S2 of the first lens 10 is concave in the near-optical axis Q; the side surface S3 of the second lens 20 is at the near-optical axis Q For the convex surface, the image side surface S4 of the second lens 20 is a concave surface at the near-optical axis q; the side surface S5 of the third lens 30 and the image side surface S6 are all convex surfaces; the fourth lens 40 side surface S7 The near-optical axis Q is ...

no. 2 example

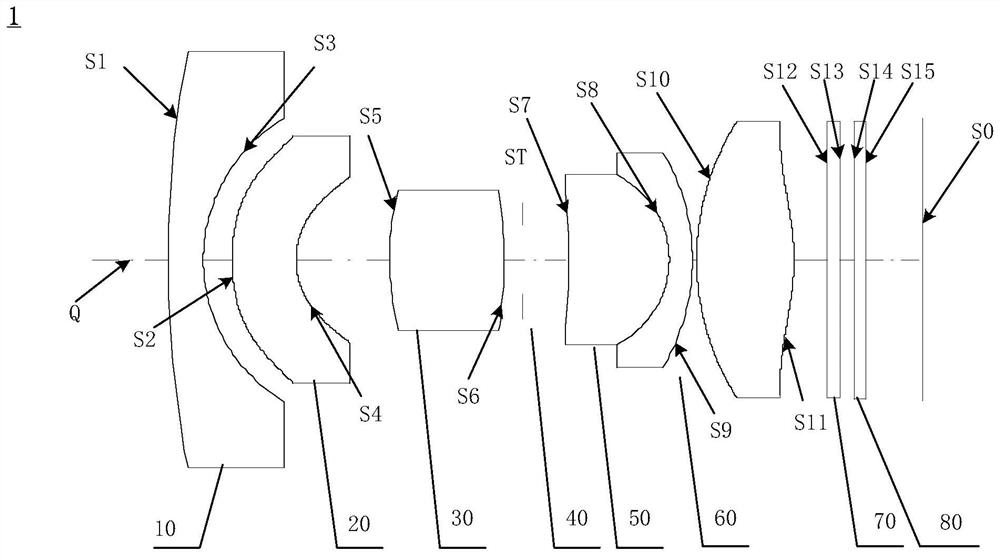

[0143] Refer image 3 and Figure 4 The optical imaging system 1 in the second embodiment sequentially includes a first lens 10 having a negative and flexible force, a second lens 20 having a ductility, and a third lens 30 having a positive flexible force. The fourth lens 40 having a divergetic force, a fifth lens 50 having a negative flexible force, a sixth lens 60, a filter 70, and a protective glass 80 having a positive flexible force.

[0144] Wherein, the side surface S1 of the first lens 10 is a convex surface at a proximal optical axis Q, and the image side surface S2 of the first lens 10 is concave in the near-optical axis Q; the side surface S3 of the second lens 20 is at the near-optical axis Q For the convex surface, the image side surface S4 of the second lens 20 is a concave surface at the near-optical axis q; the side surface S5 of the third lens 30 and the image side surface S6 are all convex surfaces; the fourth lens 40 side surface S7 The near-optical axis Q is a co...

no. 3 example

[0154] Refer Figure 5 and Image 6 , The optical imaging system 1 in the third embodiment includes a first lens 10 having a negative flexible force in the image side, a second lens 20 having a negative flexible force, a third lens 30 having a divergetic force. The fourth lens 40 having a divergetic force, a fifth lens 50 having a negative flexible force, a sixth lens 60, a filter 70, and a protective glass 80 having a positive flexible force.

[0155] Wherein, the side surface S1 of the first lens 10 is a convex surface at a proximal optical axis Q, and the image side surface S2 of the first lens 10 is concave in the near-optical axis Q; the side surface S3 of the second lens 20 is at the near-optical axis Q For the convex surface, the image side surface S4 of the second lens 20 is a concave surface at the near-optical axis q; the side surface S5 of the third lens 30 and the image side surface S6 are all convex surfaces; the fourth lens 40 side surface S7 The near-optical axis Q is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum viewing angle | aaaaa | aaaaa |

| Maximum viewing angle | aaaaa | aaaaa |

| Maximum viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com