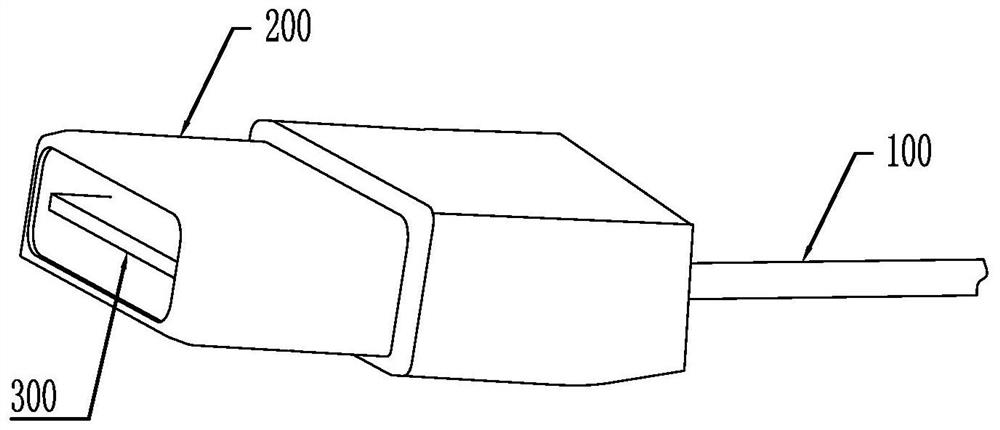

AOC high-speed connector plug and connector assembly

A technology of high-speed connectors and plugs, applied in medical/surgical connectors, parts and connections of connecting devices, etc., can solve problems such as long transmission distance, weak anti-interference ability, and easily affected transmission signals, and achieve anti-interference Strong capability, miniaturized size, and the effect of improving the quality of transmission signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

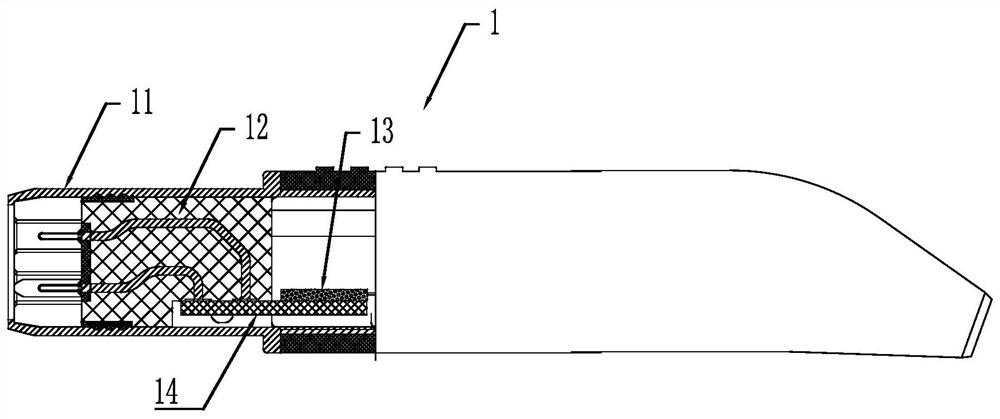

Examples

Embodiment 2

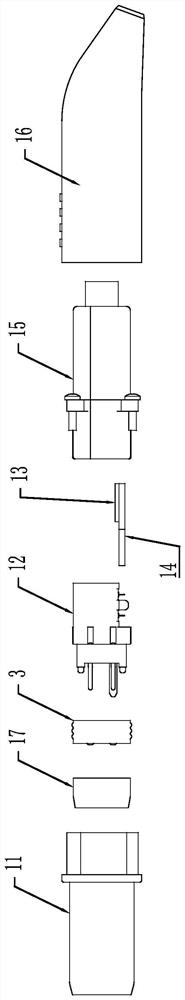

[0056] Such as Figure 19 , the difference between this embodiment and the first embodiment of the connector assembly is only the connector plug, the difference between this embodiment and the connector plug of the first embodiment is that the existing straight circular pins can be used for the plug contacts Therefore, it is not necessary to bend the plug contacts, but to "bend" the plug printed board 14, that is, to also make the electrical contact parts have "bending parts", which can also reduce the size of the connector plug. At this time, the plug printed board adopts a rigid-flexible board, which includes a first rigid printed board 141, a second rigid printed board 142, and a flexible board 143 connecting the two rigid printed boards. The first rigid printed board If it is set vertically and the second rigid printed board is set horizontally, then the first rigid printed board and the second rigid printed board are perpendicular to each other, realizing the 90° bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com