Riveting mechanism and automatic lead assembling equipment

A technology of assembly equipment and riveting, which is applied in the direction of electromechanical devices, electric components, and manufacturing of motor generators, etc., which can solve the problems of increasing labor costs, affecting processing effects, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

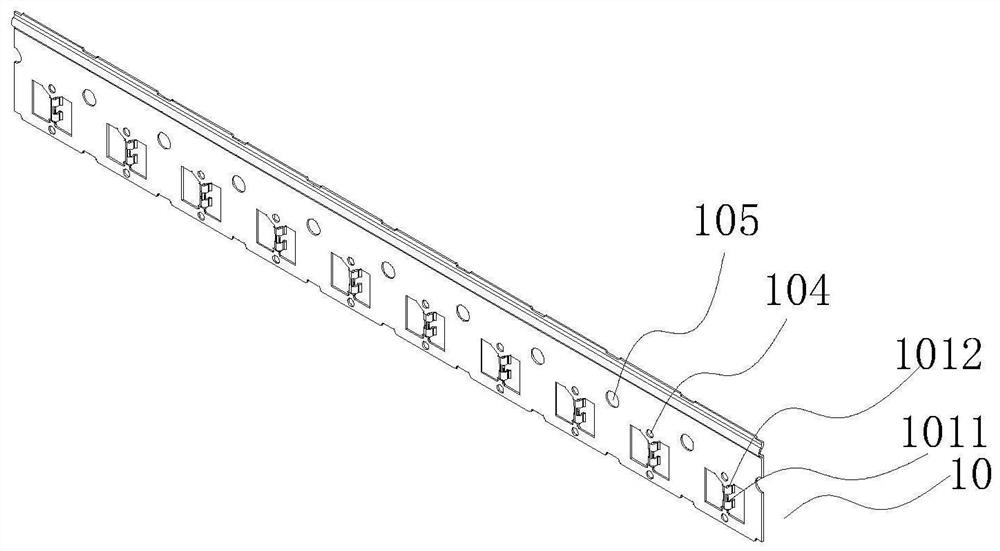

[0061] Refer to attached Figure 1-7 As shown, an automated lead wire assembly equipment includes a fixed base 11 for fixing a lead frame 10, a riveting block 12, a first fixing member 14 for clamping a lead wire 13, a riveting power source 15, a rotating driving source 16, a second A power source 17 and a wire straightening mechanism 18 .

[0062] The lead frame 10 is provided with several lead grooves 101 adapted to the lead wires 13. The number of lead grooves 101 here can be set according to actual needs. The lead frame 10 in this embodiment is provided with ten lead grooves 101. Ten wire slots 101 are arranged in a single row at equal intervals, and each wire slot 101 has the same structure.

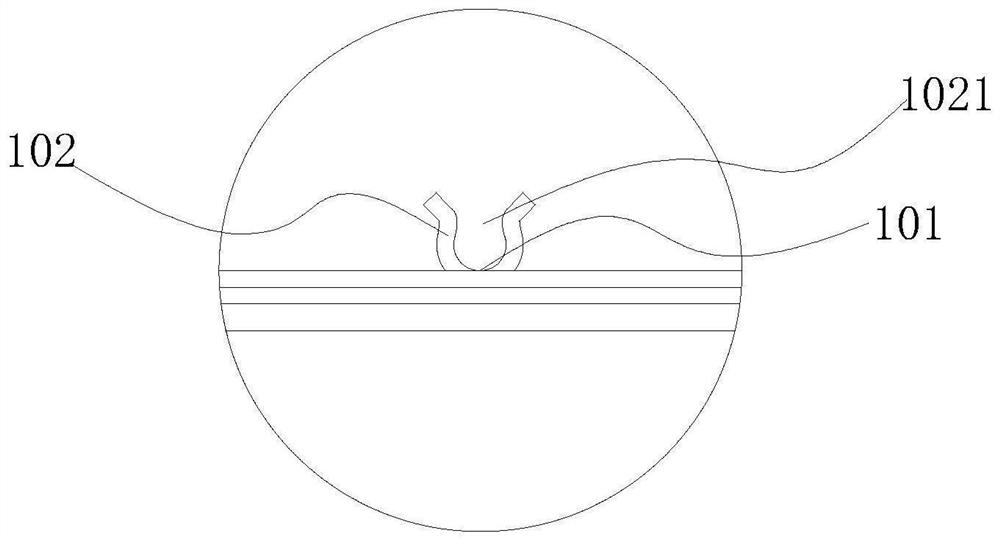

[0063] The lead slot 101 is provided with a first through slot 1011 and a second through slot 1012 , the first through slot 1011 and the second through slot 1012 are arranged front and rear, and the two through slots are arranged concentrically. Both sides of the first through-slo...

Embodiment 2

[0075] Refer to attached Figure 8-16 As shown, an automatic lead wire assembly equipment, a riveting mechanism 21, a running mechanism 22, a cutting mechanism 23, a tinning mechanism 24, a flux circulation mechanism 25, a first feeding mechanism 26, a second feeding mechanism 27, and a feeding mechanism 28 , the first receiving mechanism 29, the second receiving mechanism 30 and an alarm mechanism.

[0076] The specific structure of the riveting mechanism 21 has been described in detail in Embodiment 1, so it will not be further described here.

[0077] The running mechanism 22 includes a turntable 221 and a second driving source 222 , the first fixing members 14 are distributed in a circular array on the turntable 221 , and the second driving source 222 drives the turntable 221 to rotate. Here, the number of first fixing parts 14 can be selected according to actual needs, and the second driving source 222 is located below the turntable 221 to drive the turntable 221 to rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com