Full-automatic smoke discharging and fire extinguishing system

A fire extinguishing system and automatic fire extinguishing technology, which is applied in the field of fire extinguishing systems, can solve the problems that dense smoke cannot be discharged from buildings in time, and the fire extinguishing effect is insufficient, so as to achieve the effect of improving dust suppression and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-9 The application is described in further detail.

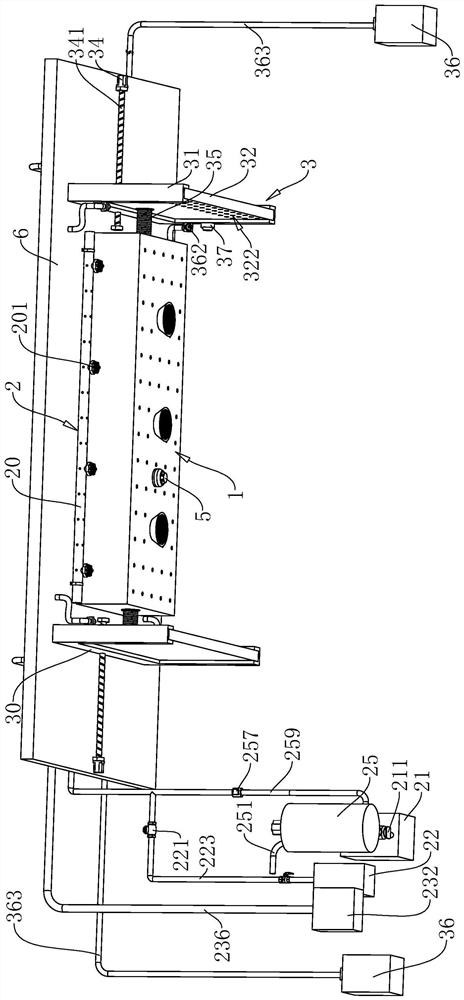

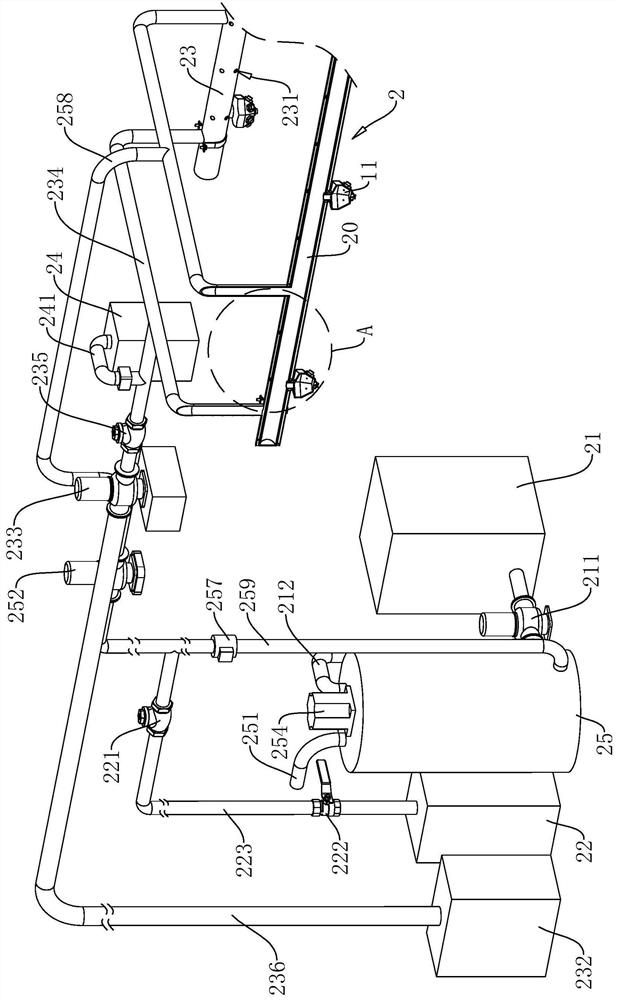

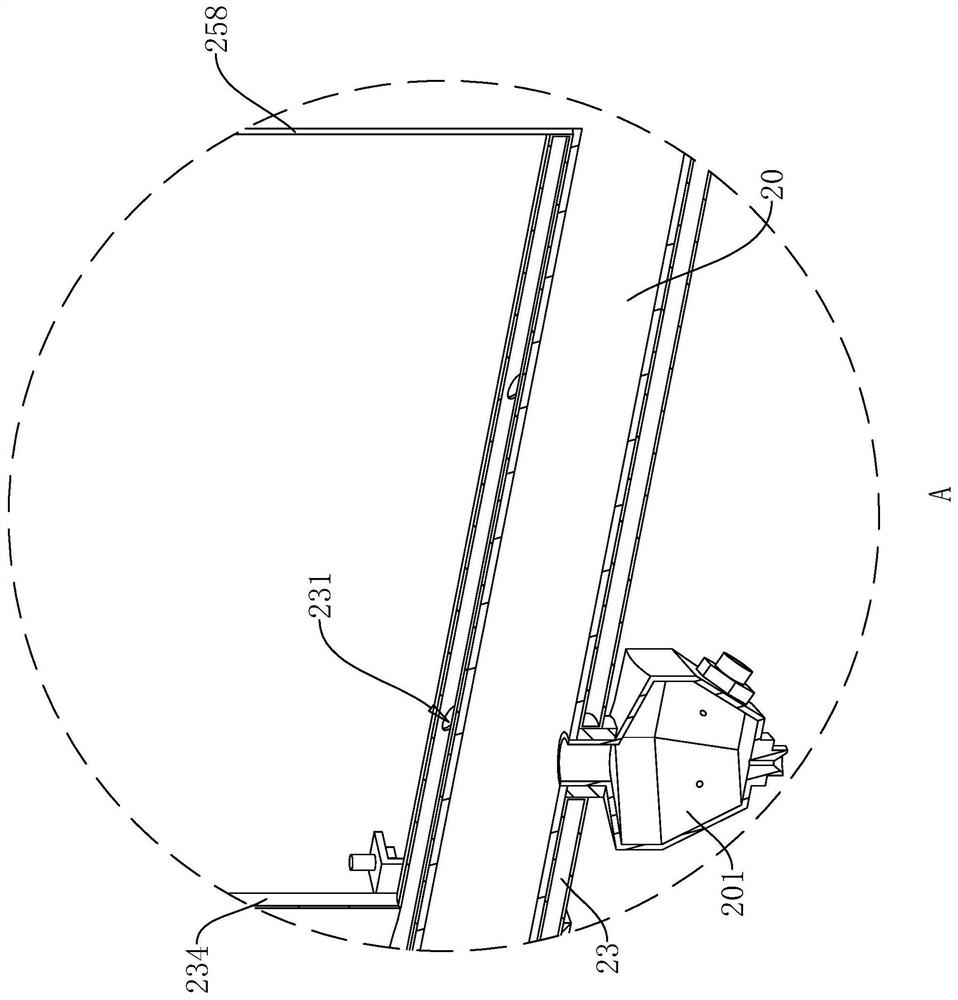

[0044] The embodiment of the present application discloses a fully automatic smoke exhaust and fire extinguishing system. refer to figure 1 , a fully automatic smoke exhaust and fire extinguishing system, comprising an automatic smoke exhaust module 1, an automatic water mist fire extinguishing module 2 and a smoke range control module 3 installed on the bottom surface of a roof 6 of a building. Among them, the automatic smoke exhaust module 1 extends along the length direction of the bottom surface of the roof 6 of the building, and the outer wall of the automatic smoke exhaust module 1 is provided with a fire prevention and cooling mechanism; the fine water mist automatic fire extinguishing module 2 is arranged parallel to the extension direction of the automatic smoke exhaust module 1; the smoke range The control module 3 includes smoke-shielding vertical walls respectively arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com