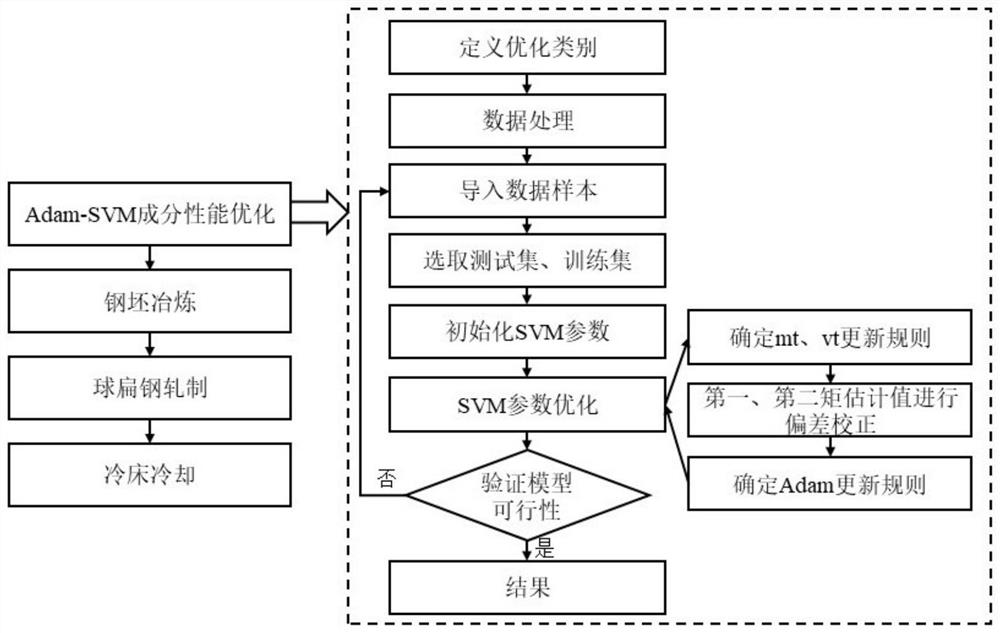

A preparation method of ah36 hot rolled flat bulb steel based on adam-svm model

An AH36, bulb flat steel technology, applied in nuclear method, metal rolling, metal rolling, etc., can solve the problems of cumbersome composition design process, high R&D cost, long R&D cycle, etc., to avoid dimensional disaster and improve accuracy degree, to achieve the effect of organic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: After using the Adam-SVM model to optimize the element composition of AH36 hot-rolled flat bulb steel, smelting and casting according to the above composition range to obtain a billet with a cross-section of 280mm × 165mm, and then detect the composition of the billet, as shown in the table 1.

[0055] Table 1 Composition of steel billets (wt.%)

[0056]

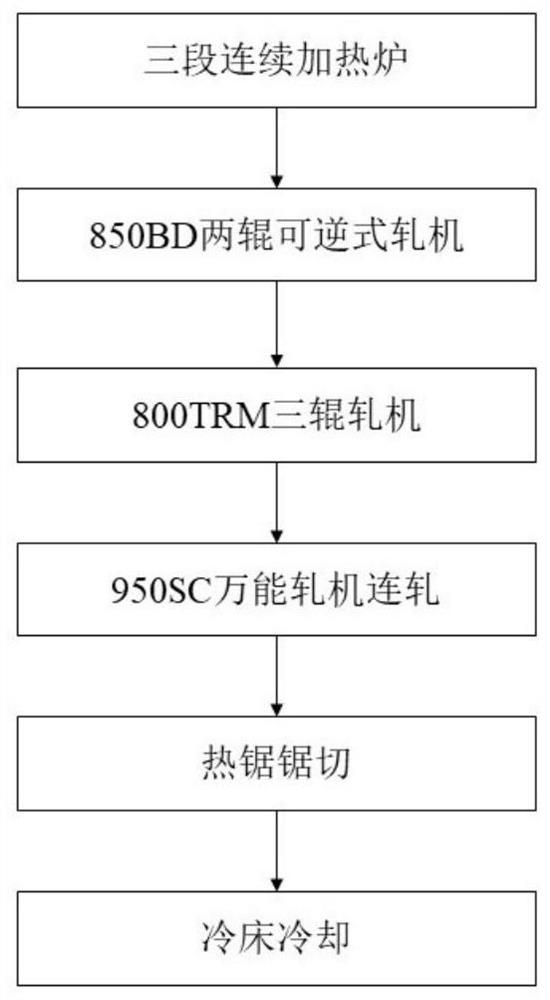

[0057] Rolling was carried out according to the order of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mill, and the rolling passes were 5 / 3 / 1 / 1 respectively. After rolling, HP370×13 specification bulb flat steel was obtained.

[0058] Table 2 Mechanical properties

[0059]

Embodiment 2

[0060] Example 2: After using the Adam-SVM model to optimize the element composition of AH36 hot-rolled flat bulb steel, smelting and casting according to the above composition range to obtain a billet with a cross-section of 280mm × 165mm, and then detect the composition of the billet, as shown in the table 3.

[0061] Table 3 Composition of steel billets (wt.%)

[0062]

[0063] Rolling was carried out in the order of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mills, and the rolling passes were 5 / 3 / 1 / 1 respectively. After rolling, HP370×13 specification bulb flat steel was obtained.

[0064] Table 4 Mechanical properties

[0065]

Embodiment 3

[0066] Example 3: After using the Adam-SVM model to optimize the element composition of AH36 hot-rolled flat bulb steel, smelting and casting according to the above composition range to obtain a billet with a cross-section of 280mm × 165mm, and then detect the composition of the billet, as shown in the table 5.

[0067] Table 5. Composition of steel billets (wt.%)

[0068]

[0069] Rolling was carried out in the order of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mill, and the rolling passes were 5 / 3 / 1 / 1 respectively. After rolling, HP370×13 specification bulb flat steel was obtained.

[0070] Table 6 Mechanical properties

[0071]

[0072] In order to further highlight the effect of the present invention, the following two groups of comparisons are provided. When the Adam-SVM algorithm is not used to classify and optimize the composition properties, and the process optimization is not performed (the rolling temperature is above 1200°C), the composition properties are as shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com