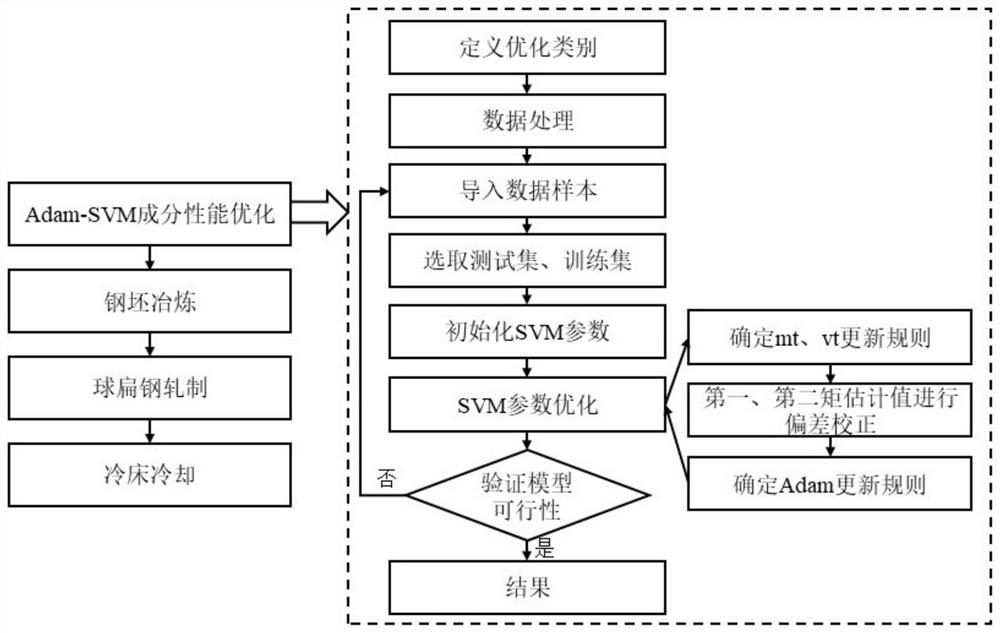

AH36-grade hot-rolled flat-bulb steel preparation method based on Adam-SVM model

An AH36, bulb flat steel technology, applied in nuclear method, metal rolling, metal rolling, etc., can solve the problems of cumbersome composition design process, high R&D cost, long R&D cycle, etc., to avoid dimensional disaster and improve accuracy degree, to achieve the effect of organic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: After using the Adam-SVM model to optimize the elemental composition of AH36 grade hot-rolled bulbous flat steel, smelting and casting were carried out according to the above-mentioned composition range to obtain a billet with a cross-section of 280mm×165mm, and then the composition of the billet was detected, as shown in the table 1.

[0055] Composition (wt.%) of billet of table 1

[0056]

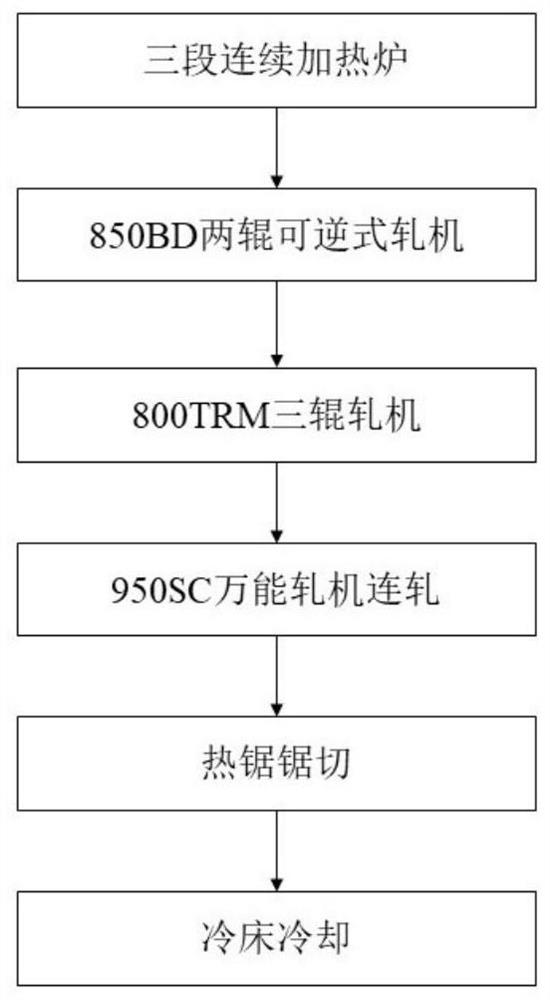

[0057] Rolling is carried out in accordance with the sequence of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mills, and the rolling passes are 5 / 3 / 1 / 1 respectively. After rolling, the spherical flat steel of HP370×13 specification is obtained, and its mechanical properties are shown in Table 2.

[0058] Table 2 Mechanical Properties

[0059]

Embodiment 2

[0060] Example 2: After using the Adam-SVM model to optimize the elemental composition of AH36 hot-rolled bulbous flat steel, smelting and casting according to the above-mentioned composition range to obtain a billet with a cross-section of 280mm×165mm, and then detecting the composition of the billet, see Table 3.

[0061] Composition (wt.%) of billet of table 3

[0062]

[0063] Rolling is carried out in accordance with the sequence of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mills, and the rolling passes are 5 / 3 / 1 / 1 respectively. After rolling, the spherical flat steel of HP370×13 specification is obtained, and its mechanical properties are shown in Table 4.

[0064] Table 4 mechanical properties

[0065]

Embodiment 3

[0066] Example 3: After using the Adam-SVM model to optimize the elemental composition of AH36 grade hot-rolled bulbous flat steel, smelting and casting according to the above-mentioned composition range to obtain a billet with a section of 280mm×165mm, and then detecting the composition of the billet, see Table 5.

[0067] Composition (wt.%) of billet of table 5

[0068]

[0069] Rolling was carried out in accordance with the sequence of 850BD / 800TRM / 950SCI / 950SCⅡ rolling mill, and the rolling passes were 5 / 3 / 1 / 1 respectively. After rolling, the spherical flat steel of HP370×13 specification was obtained, and its mechanical properties are shown in Table 6.

[0070] Table 6 mechanical properties

[0071]

[0072] In order to further highlight the effect of the present invention, the following two groups of comparisons are provided. When the Adam-SVM algorithm is not used to classify and optimize the design of the composition performance, and when the process optimizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com