Chip surface defect classification device and method based on deep learning

A defect classification and deep learning technology, applied in the field of chip surface defect classification devices based on deep learning, can solve problems such as difficulty in meeting the training data demand of deep convolutional neural networks, affecting model accuracy, and limited number of defect pictures, etc. The effect of improving classification accuracy, improving training accuracy, and improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

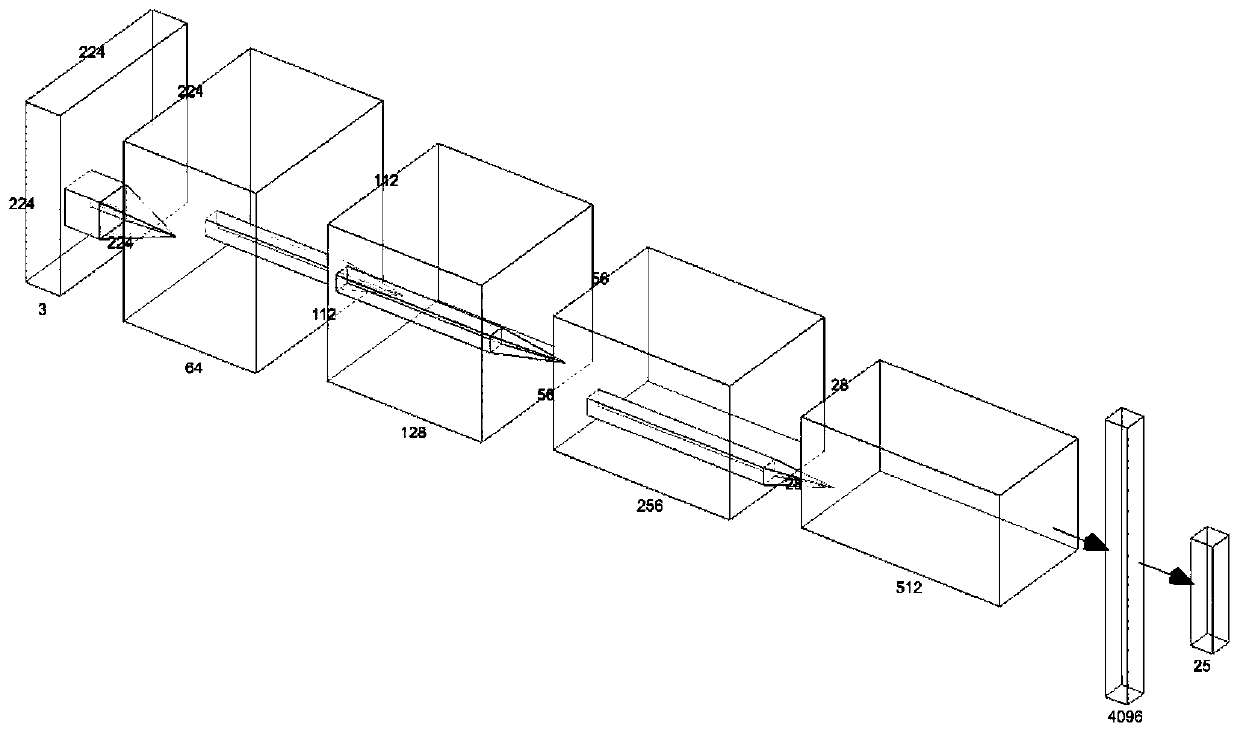

[0056] In the present invention, the identification model can be a deep convolutional neural network model, and its specific training steps are:

[0057] Step 1: Set the training image size in the training image set to 3 channels 224×224; in this embodiment, it can also be set to 1 channel image, and the channel size can be any value between 0-256;

[0058] Step 2: Input the training image to the input layer of the deep convolutional neural network model, and the size of the input layer of the deep convolutional neural network model is 224×224×3;

[0059] Step 3: The training image output from the input layer of the deep convolutional neural network model is input to the first convolutional layer C1 of the deep convolutional neural network model; the size of the first convolutional layer C1 of the deep convolutional neural network model is 224×224 ×64, using ReLU as the activation function; in this embodiment, the size of the sliding matrix can also be other values such as 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com