Plate type heat exchanger and method of manufacturing heat exchanger

A heat exchanger, flat-plate technology, applied in the field of flat-plate heat exchangers, can solve problems such as poor brazing, damage to flat-plate adhesion, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] (Embodiment 1)

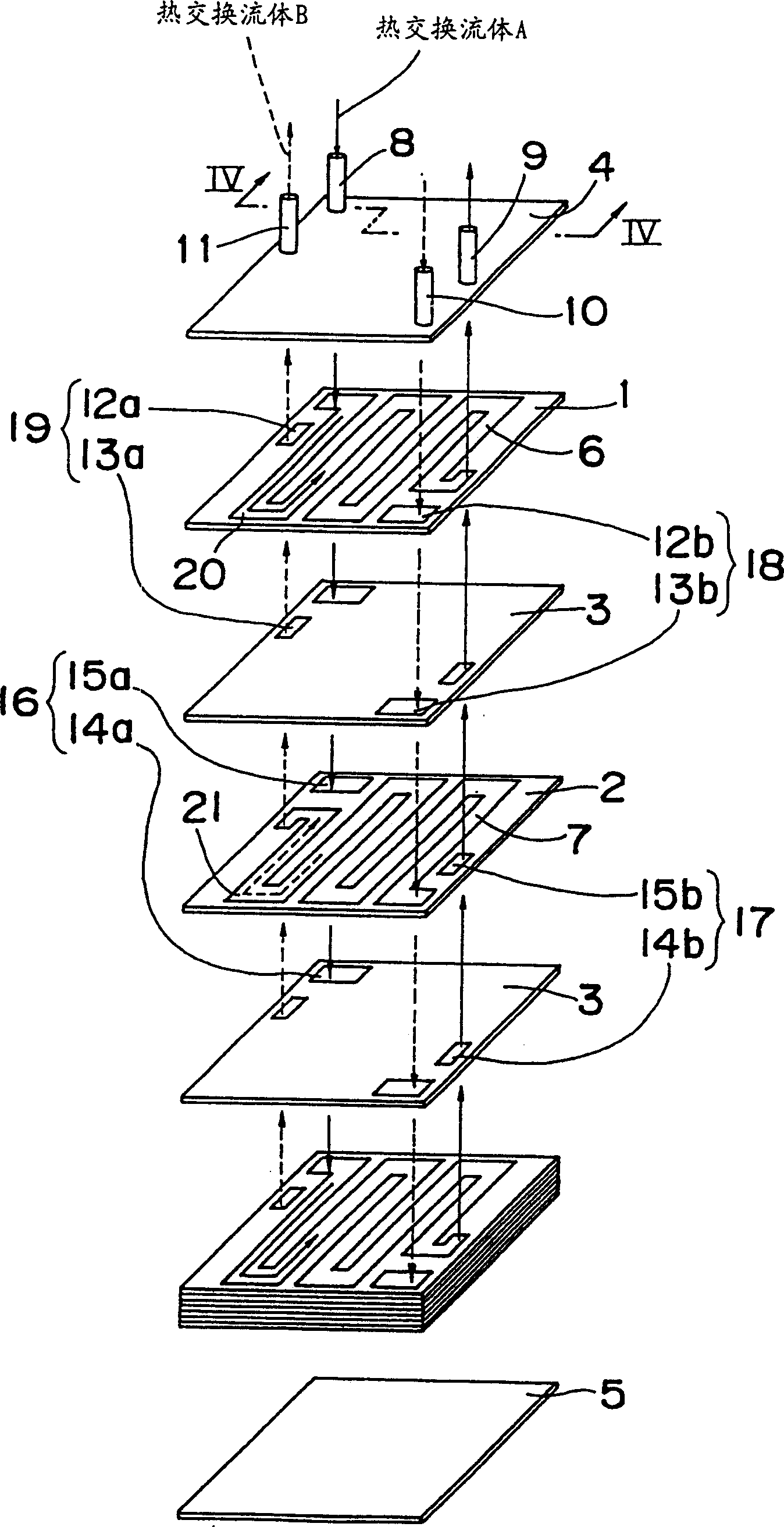

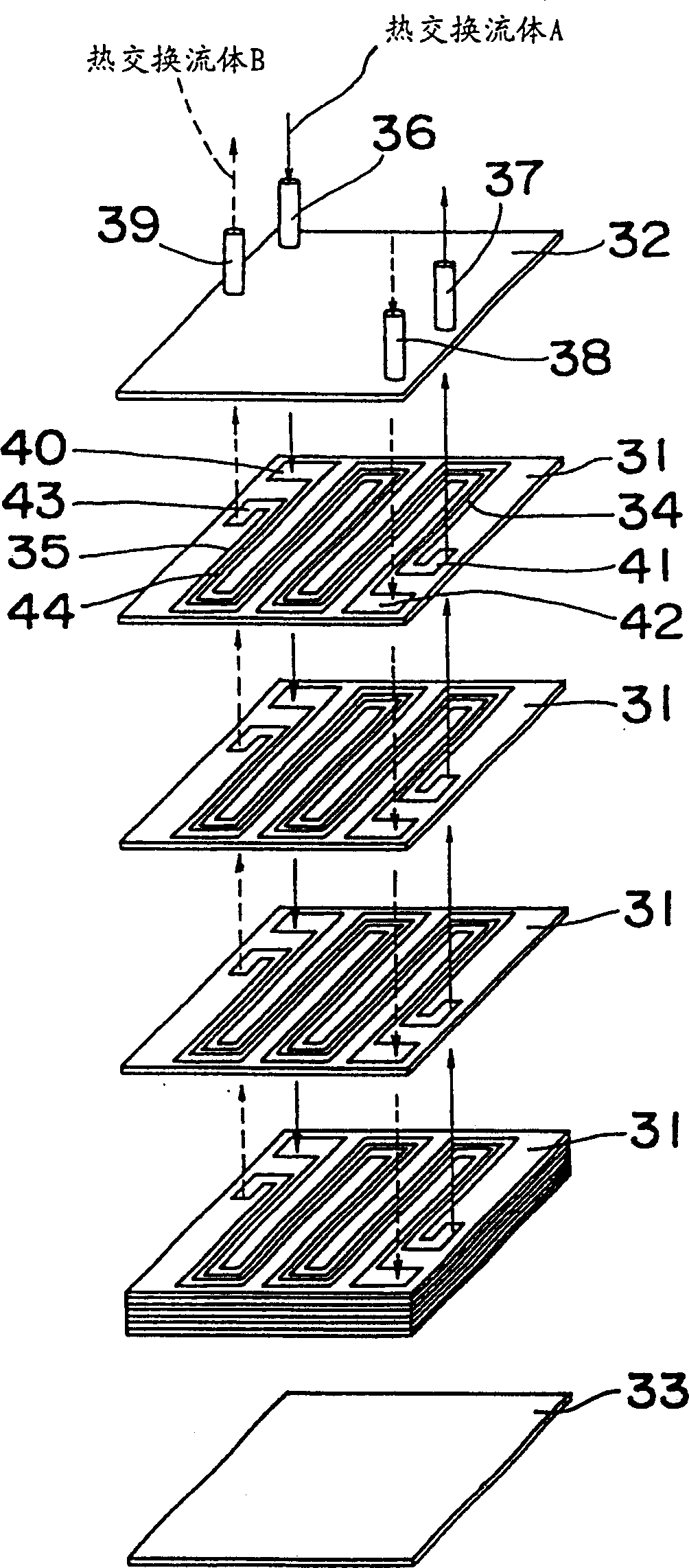

[0032] figure 1 The plate heat exchanger according to Embodiment 1 of the present invention is partially disassembled in the figure to clearly show its internal structure.

[0033] In this flat plate heat exchanger, a plurality of flat plates are arranged between a pair of end plates, on which a flow channel has been formed through the plate surface, and a plurality of flow channels that are not connected to each other are arranged in the planes of different plates among the plurality of flat plates. The fluids flowing in multiple channels at the same time flow in opposite directions.

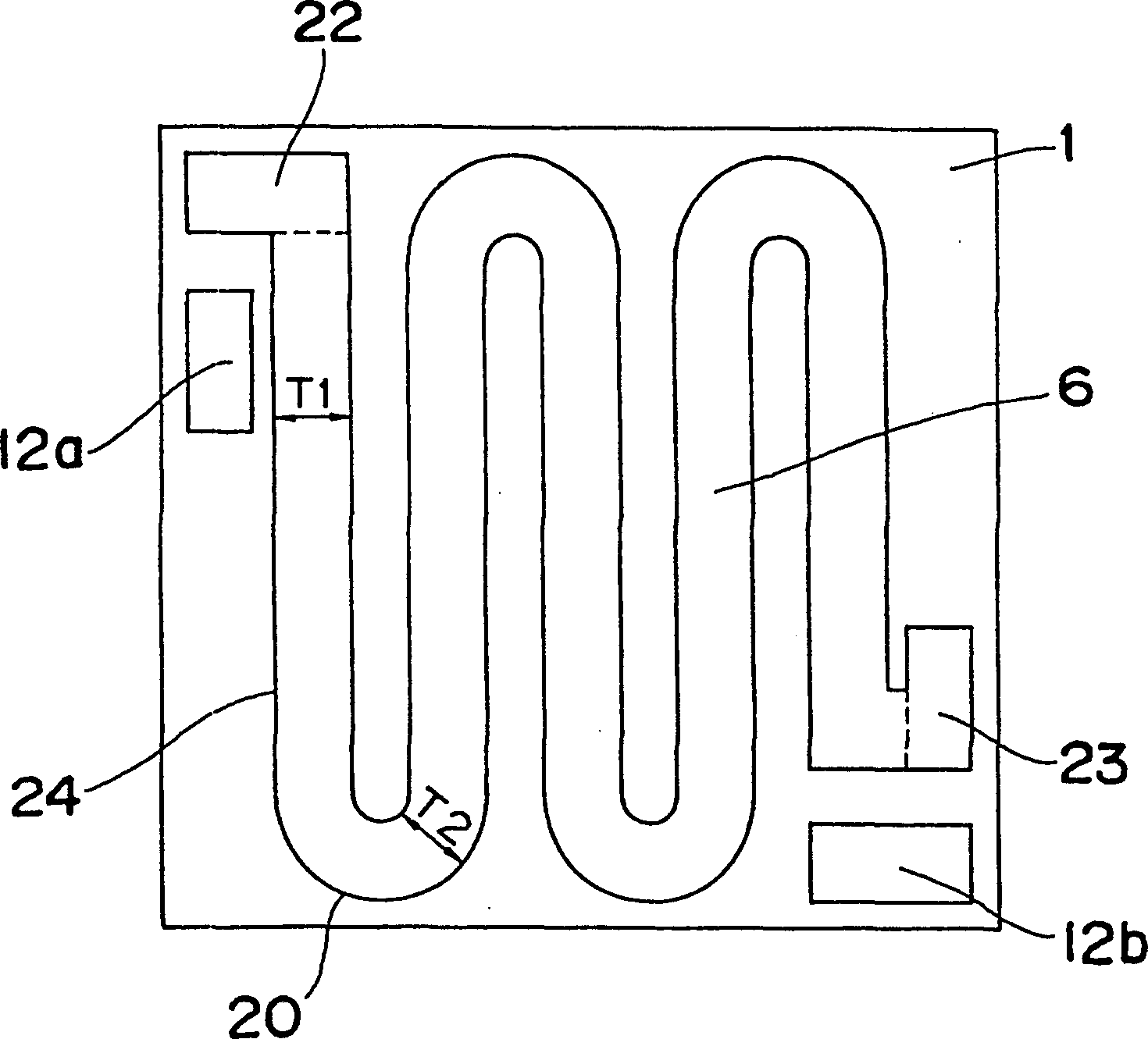

[0034] Specifically, as figure 1 As shown, a plurality of flow channel plates 1 and 2 are alternately stacked between a pair of end plates 4 and 5 with a partition plate 3 interposed therebetween. The heat exchanger fluid passing through the plate surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com