Water jet vacuum pump

A water jet vacuum and drain pipe technology, which is applied to jet pumps, pumps, non-displacement pumps, etc., can solve the problem that the extrusion force of the water flow is reduced, the horizontal card is difficult to discharge outward, and the small stones follow the water flow into the vacuum chamber, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

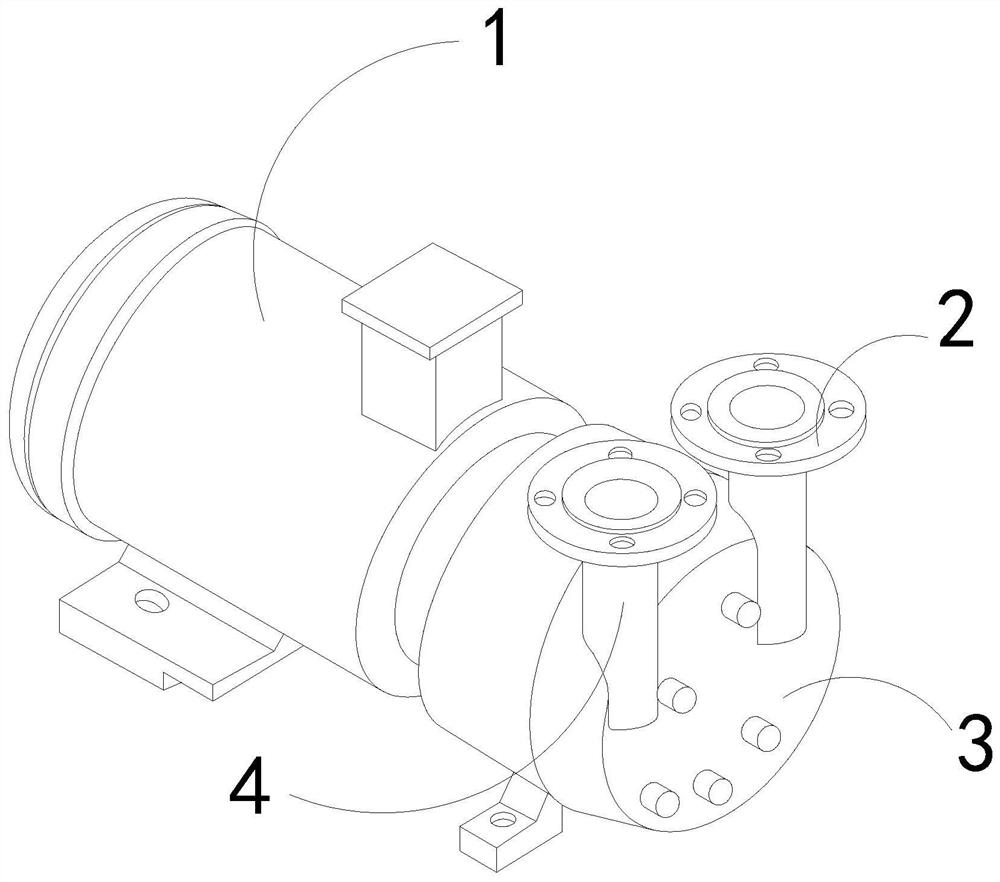

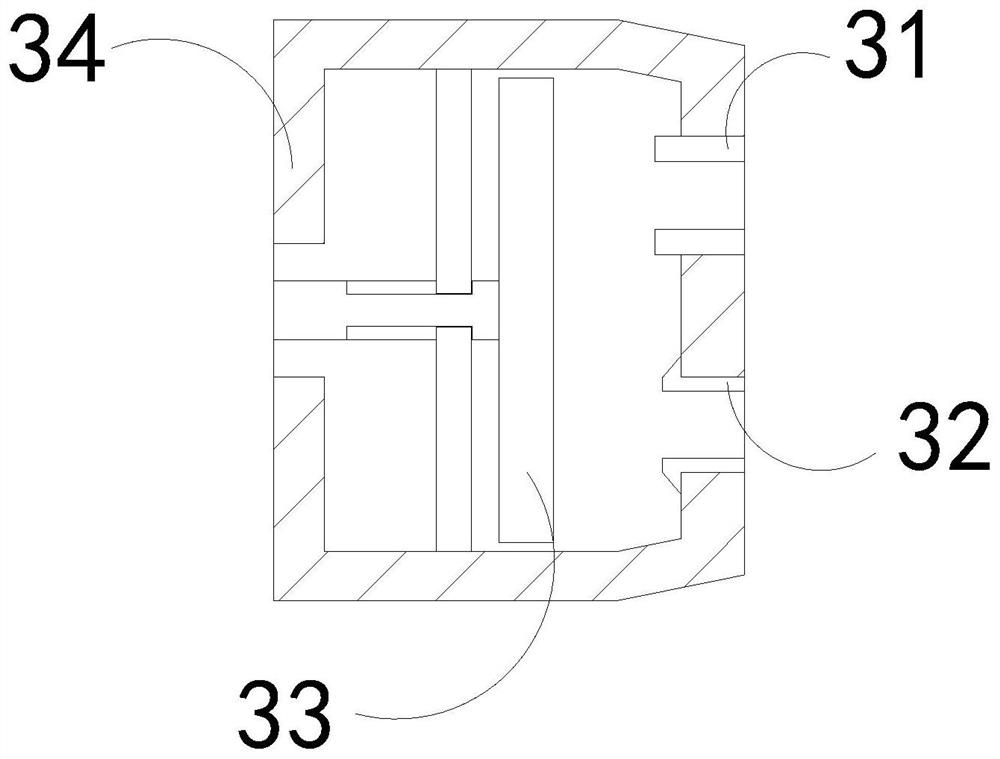

[0027] The invention provides a water jet vacuum pump, the structure of which includes a driving end 1, a drain pipe 2, a booster chamber 3, and a water inlet pipe 4. The drain pipe 2 is embedded in the booster chamber 3, and the water inlet pipe 4 is connected to The pressure chamber 3 is connected, and the pressure chamber 3 is integrated with the driving end 1; the pressure chamber 3 includes a water outlet 31, a water inlet 32, a booster frame 33, and an outer frame 34. The water outlet 31 Through the inner position of the outer frame 34 , the water inlet 32 is embedded in the inner position of the outer frame 34 , and the booster frame 33 is movably engaged with the outer frame 34 .

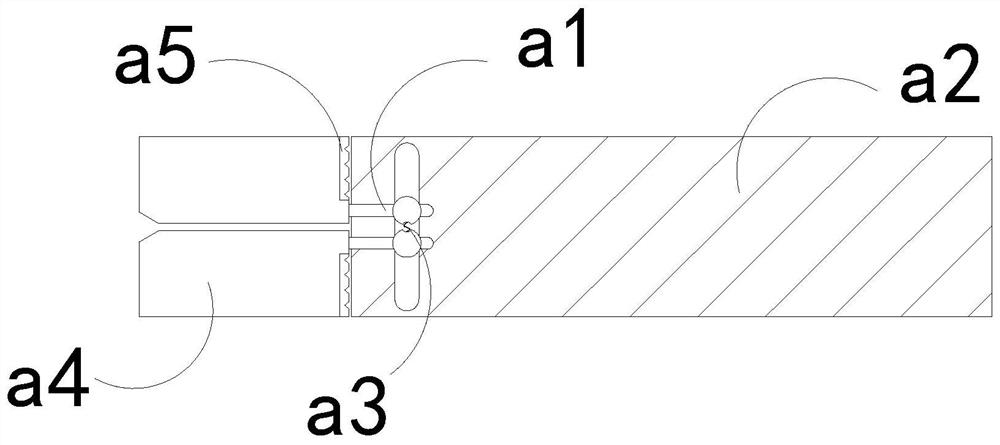

[0028] Wherein, the water outlet 31 includes a linkage rod a1, a plate surface a2, a pull-back strip a3, a clamping plate a4, and a wear-increasing surface a5. The linkage rod a1 is movably engaged with the plate surface a2, and the...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the breaker bar b3 includes a fixed plate b31, an adsorption block b32, and a swing block b33. The adsorption block b32 is embedded in the inner position of the fixed plate b31, and the swing block b33 is hingedly connected with the fixed plate b31. The swing block There are two b33, and they are evenly distributed symmetrically at the left and right ends of the fixed plate b31. Through the vibration generated by the inward contraction of the mechanism, the swing block b33 can swing down along the fixed plate b31, and the adsorption block b32 adopts permanent magnets Material can generate attraction to the swing block b33 made of metal.

[0036] Wherein, the swing block b33 includes an engaging plate c1, a transition block c2, and an extrapolating block c3, the transition block c2 is movably engaged with the engaging plate c1, and the extrapolating block c3 is installed at the front end of the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com