Pipe expander

A technology of a tube expander and a machine body, which is applied in the field of tube expansion and can solve the problems of low efficiency of switching of expansion rods and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

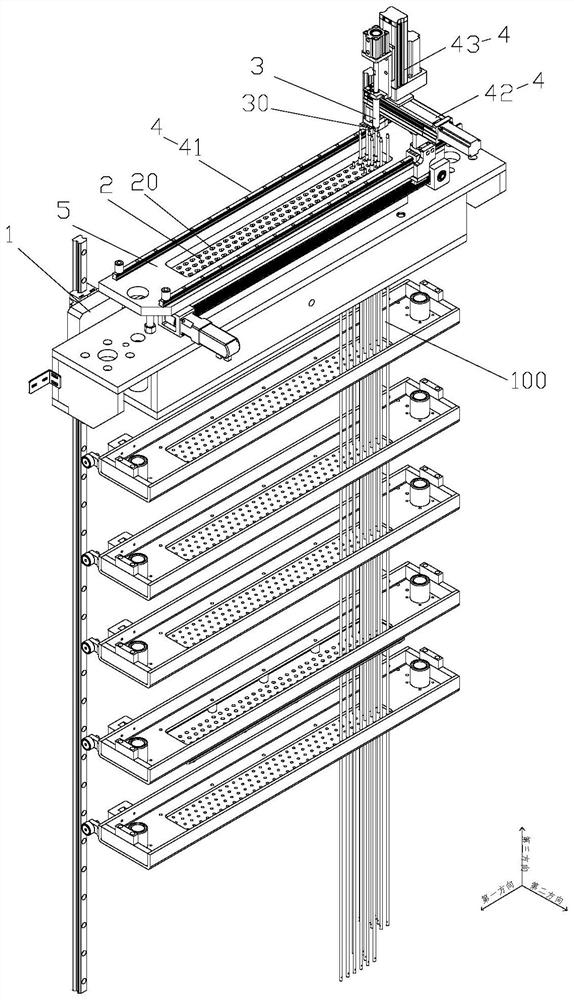

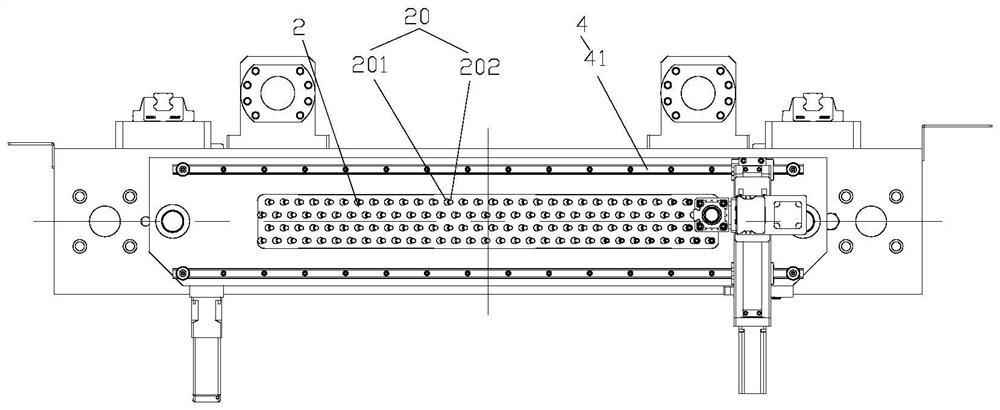

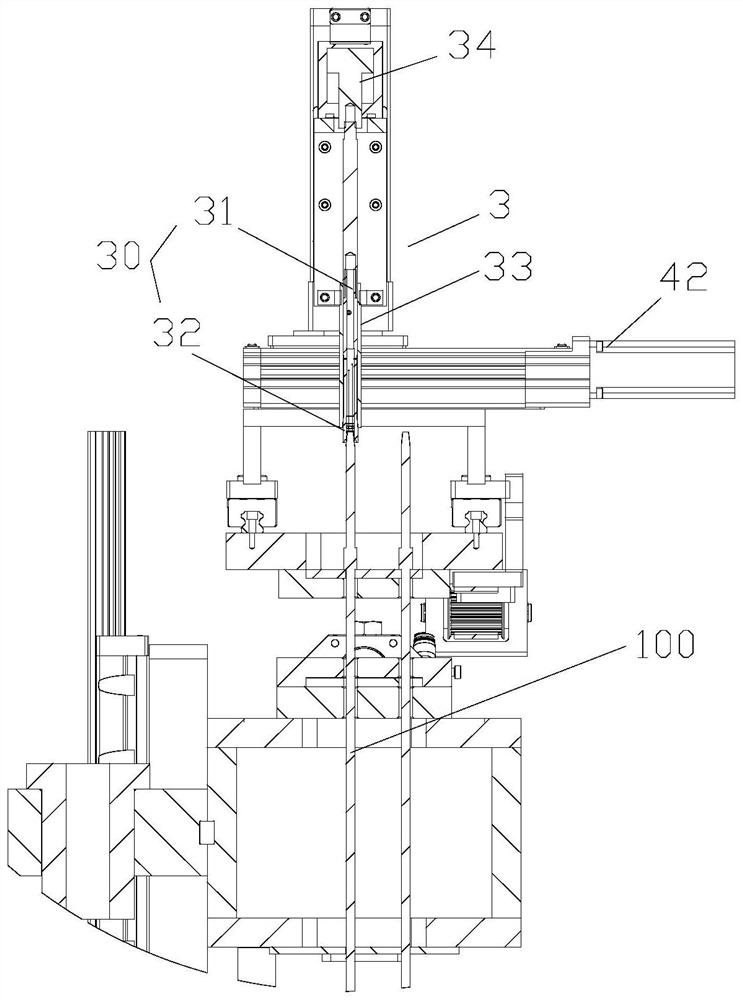

[0025] A kind of tube expander of the present invention, please refer to Figure 1 to Figure 4 , the tube expander includes: a body 1, an installation template 2 and a jaw assembly 3, the installation template 2 is installed on the body 1, the installation template 2 is movably arranged along a predetermined direction, the installation template 2 is provided with a mounting hole 20, and the workpiece passes through Set in the installation hole 20, the installation hole 20 includes a first hole 201 and a second hole 202 that communicate with each other, the aperture of the first hole 201 is larger than the aperture of the second hole 202; the jaw assembly 3 is arranged on the body 1 Above, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap