An automatic mechanical fixture for workpiece flipping that is convenient for quickly locating the position of the workpiece

A technology of workpiece position and workpiece, applied in the field of automatic mechanical fixtures for workpiece flipping and automatic mechanical fixtures, can solve the problems of affecting processing accuracy, labor intensity of workers, surface damage of workpieces, etc., to reduce the instability of clamping force and practicability. Better, high-precision machining results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

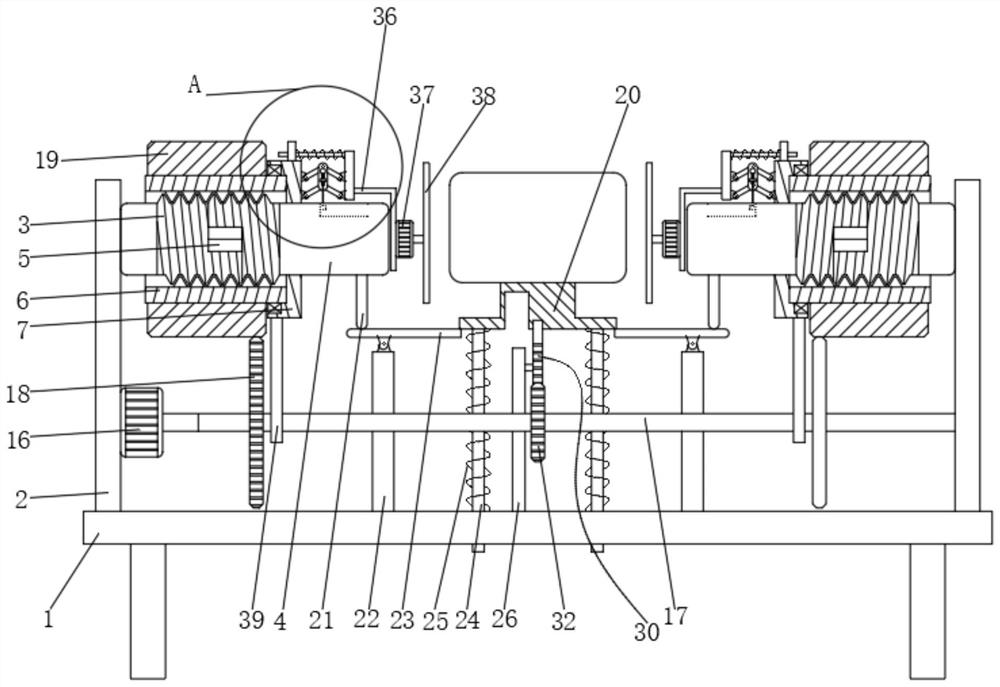

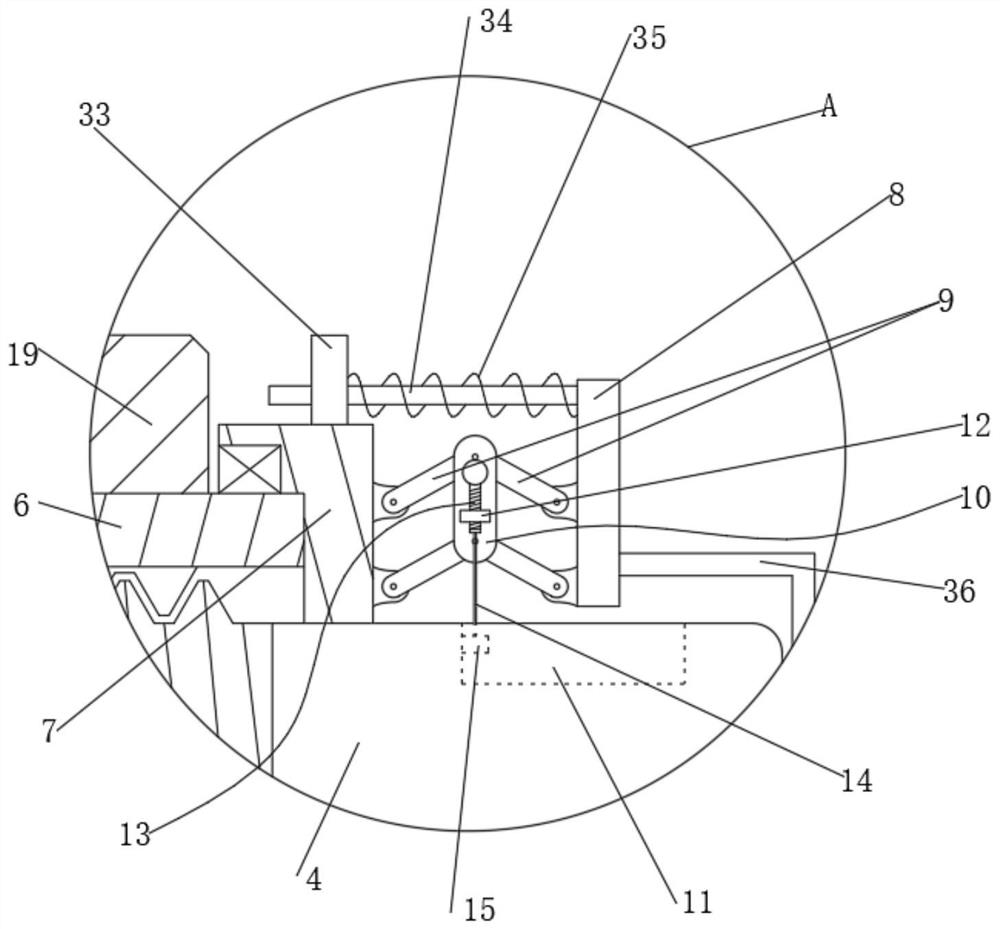

[0026] The present invention will be further described below in conjunction with the accompanying drawings (the left and right front and rear directions in the following description and the figure 1 The left and right front and rear directions are the same, just to describe the present invention).

[0027] like figure 1 As shown in the figure, an automatic mechanical fixture for workpiece flipping, which is convenient for quickly positioning the workpiece position, includes a workbench 1, and support plates 2 are fixedly arranged on both ends of the upper surface of the workbench 1, and the opposite sides of the two support plates 2 are provided with There are self-positioning clamping parts;

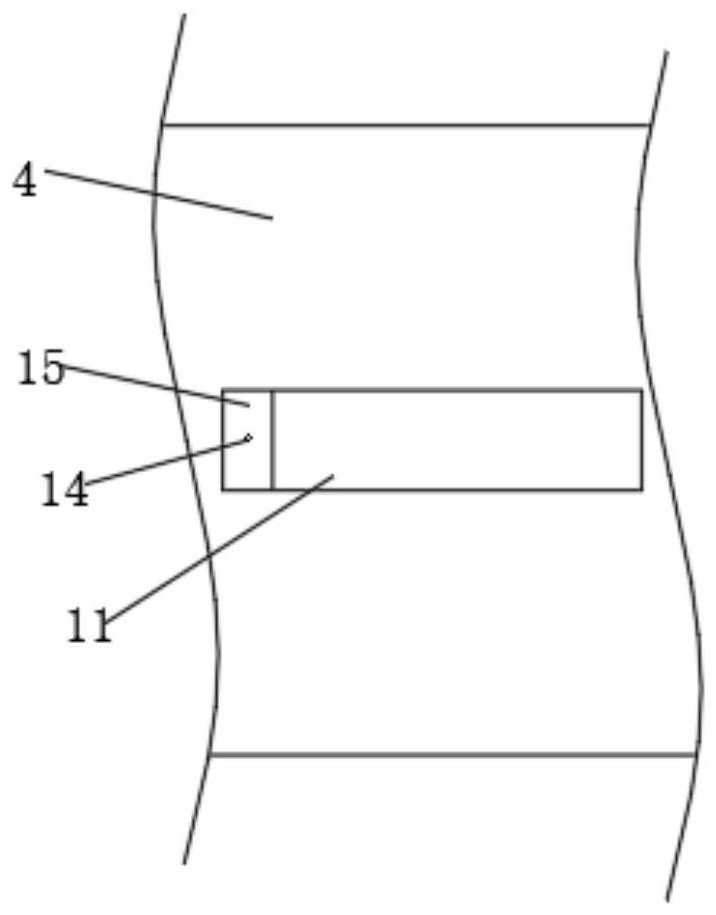

[0028] The self-positioning clamping component includes a first threaded rod 3 fixedly connected to the side of the support plate 2, and also includes a second threaded rod 4. When the first threaded rod 3 and the second threaded rod 4 are spliced into a complete screw, A gap 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com