High-speed lifting-rotating piece replenishing device

A patch and high-speed technology, which is applied in the field of high-speed lifting-rotating patch devices, can solve the problems of film production speed reduction, achieve the effect of changing efficiency loss and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

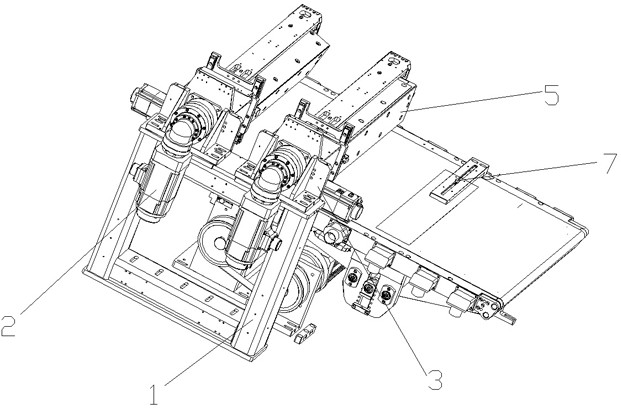

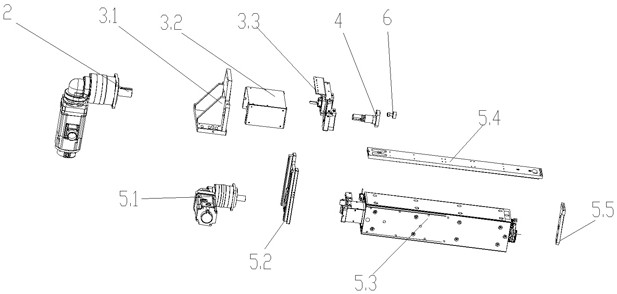

[0017] see figure 1 and figure 2 , the present invention relates to a high-speed lifting-rotating patching device for patching the gaps on the belt conveying line, which includes a patch mounting seat 1 and a plurality of patch assemblies, the patch assembly includes a patch motor 2, Fixing seat assembly 3, eccentric crankshaft 4 and flip assembly 5, the patch motor 2 is fixed on the patch mounting seat 1 through the fixing seat assembly 3, the output end of the patch motor 2 is connected to the eccentric crankshaft 4, the The eccentric crankshaft 4 drives the turning assembly 5 to move up and down. The turning assembly 5 includes a turning motor 5.1, a lifting plate 5.2 and a turning suction cup 5.3. The eccentric crankshaft 4 is connected to the lifting plate 5.2 through a connecting shaft 6, and the lifting plate 5.2 is connected to The shaft 6 is provided with a chute, the turning motor 5.1 is fixed on the lifting plate 5.2, and the output shaft of the turning motor 5.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com