A self-tightening and anti-loosening cap nut assembly

A technology of cap nuts and components, which is applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problems that cap nuts do not have anti-loosening performance, loose nut body and cap, and easy slipping wires, etc. To achieve the effect of guaranteed strength, reliable connection and convenient twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

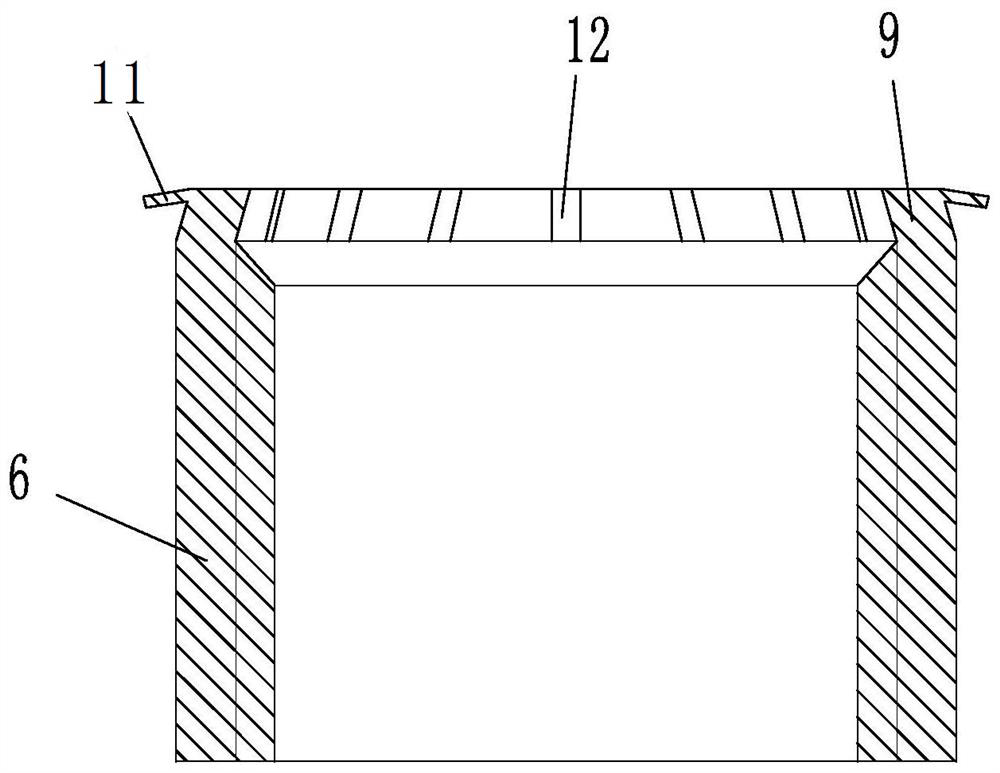

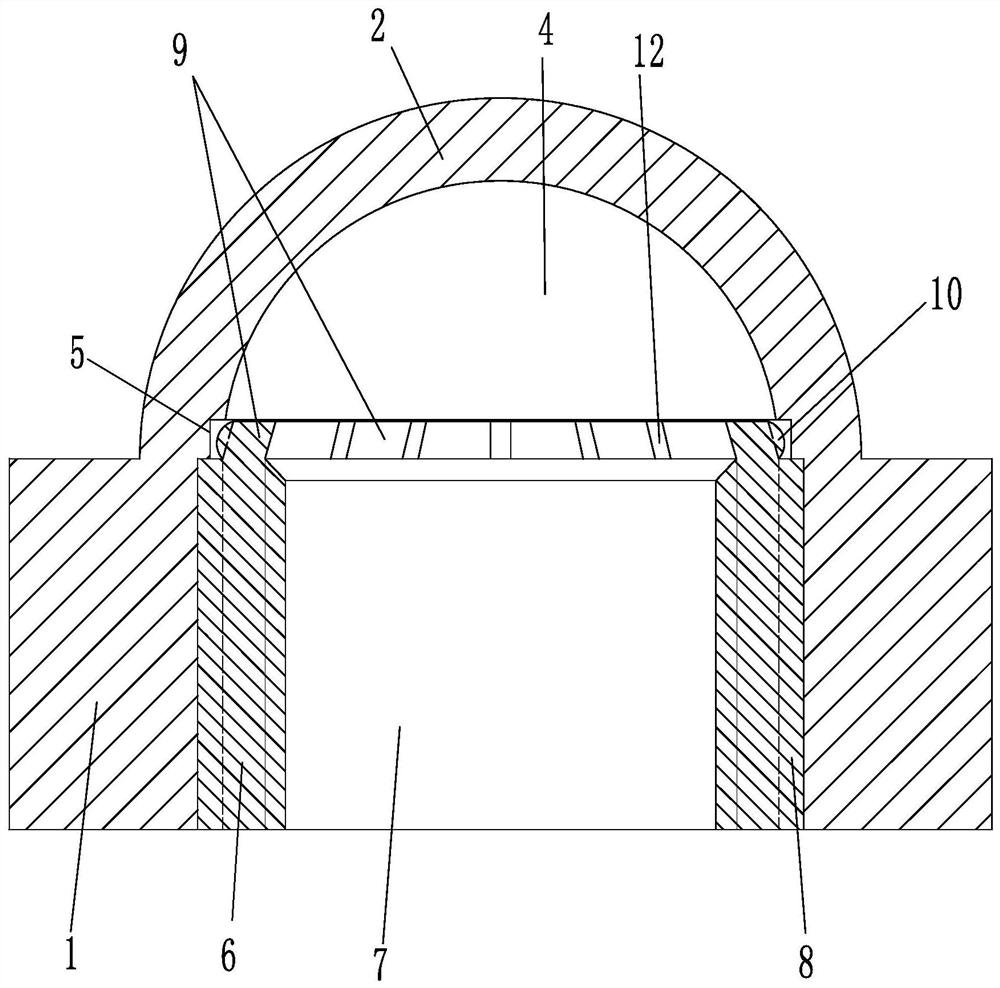

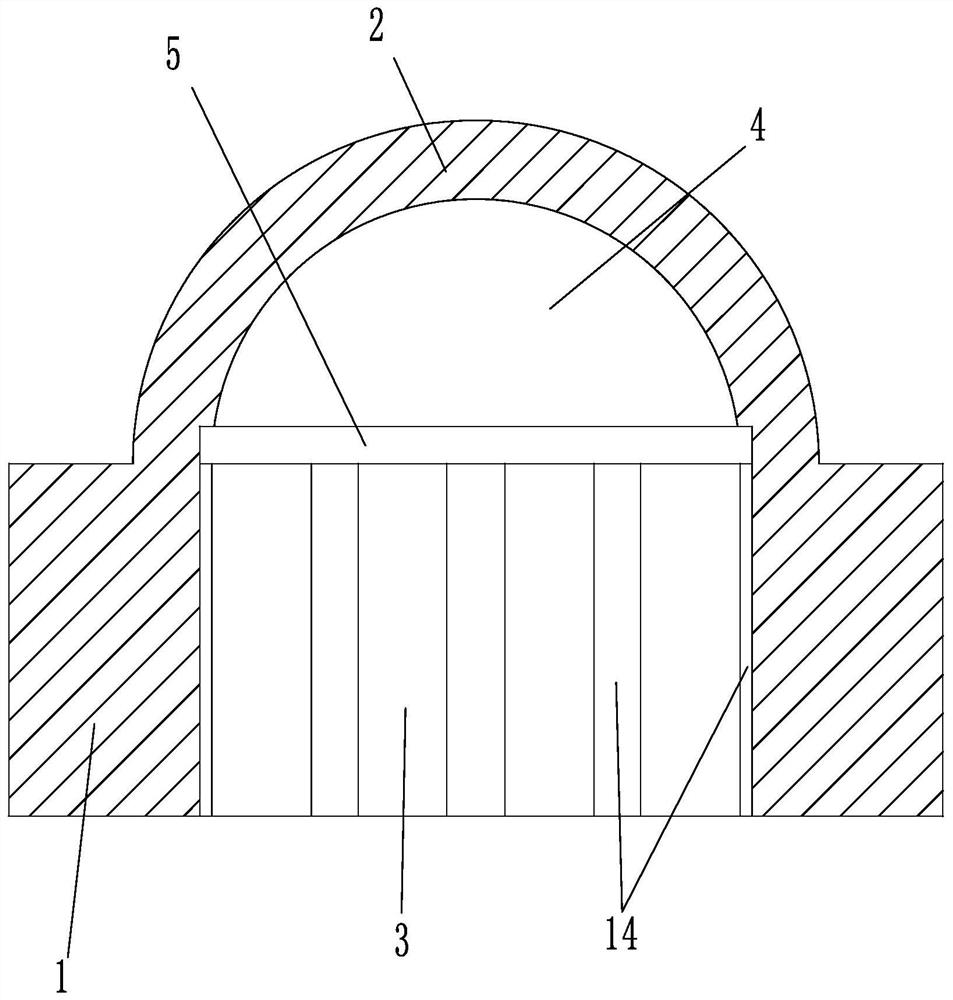

[0028] like figure 1 and figure 2As shown, a self-tightening and anti-loosening cap nut assembly is characterized in that it includes a hexagonal body 1 and a cap body 2, the hexagonal body 1 and the cap body 2 are integrally arranged, the hexagonal body 1 is provided with a through hole 3, and the cap The cover body 2 is provided with a hemispherical hole 4 coaxial with the through hole 3 , and the diameter of the through hole 3 is equal to the diameter of the hemispherical hole 4 . The through hole 3 is provided with an anti-rust sleeve 6, and the anti-rust sleeve 6 is provided with an internal threaded hole 7; the anti-rust sleeve 6 extends into the hemispherical hole 4, and the upper end surface of the anti-rust sleeve 6 and the lower end surface of the hemispherical hole 4 fit together , between the anti-rust sleeve 6 and the hemispherical hole 4, there is a matching first limiter, the first limiter includes a limiter ring groove 5 provided at the bottom of the hemisphe...

Embodiment 2

[0031] A self-tightening and anti-loosening cap nut assembly, such as image 3 and Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the axial cross-sectional shape of the expansion part 9 is an isosceles trapezoid, and the upper end of the expansion part 9 is connected with a limit elastic piece 11, and the limit elastic piece 11 and the expansion part The outer surface of 9 is provided with an acute angle, and the angle between the limit elastic piece 11 and the outer surface of the expansion part 9 is 65 degrees. The limit elastic piece 11 is located on the lower side of the upper end surface of the expansion part 9. Groove 5 fits. The limit elastic piece 11 is elongated, and after the antirust sleeve 6 cooperates with the hexagon 1 in place, the lower end of the limit elastic piece 11 is fitted to the lower side of the limit ring groove 5 . The setting of the acute angle facilitates the downward bending and elastic deformation of the limit ...

Embodiment 3

[0033] A self-tightening and anti-loosening cap nut assembly, such as Figure 5 As shown, the difference between embodiment 3 and embodiment 2 is that the angle between the limiting elastic piece 11 and the outer surface of the expansion part 9 is 85 degrees, the limiting elastic piece 11 is located on the upper side of the upper end surface of the expanding part 9, and the bolt After 13 is screwed in, the limit shrapnel 11 has a greater degree of bending and has better anti-retreat capability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com