Step-by-step direct-acting profound hypothermia electromagnetic valve

A solenoid valve and deep low temperature technology, applied in the field of solenoid valves, can solve problems such as low reliability, need for manual operation, and insufficient control capabilities, and achieve the effects of increasing the life of guiding movements, avoiding viscous wear, and improving guiding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with embodiment.

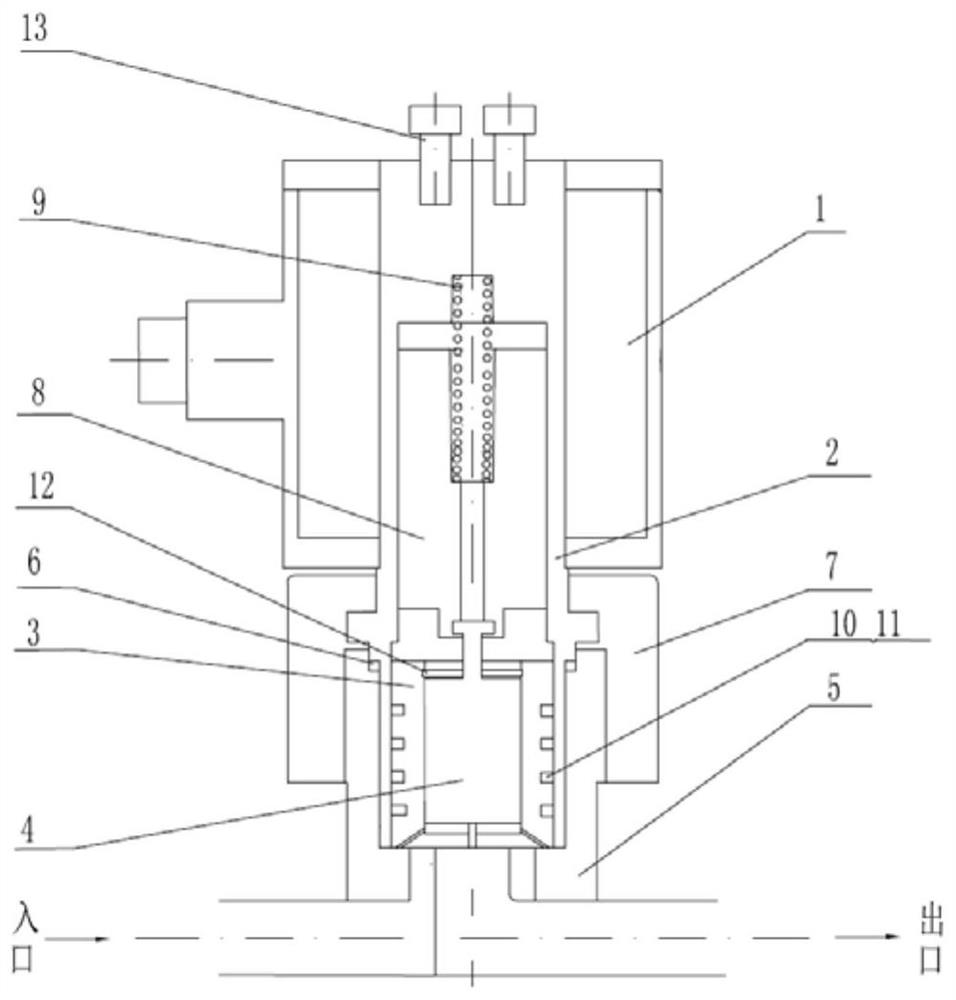

[0018] A step-by-step direct-acting cryogenic solenoid valve, such as figure 1 As shown, it includes electromagnet assembly 1, sleeve assembly 2, main live valve 3, auxiliary live valve 4, valve body, armature 8 and spring retaining ring 12,

[0019] The electromagnet assembly 1 and the sleeve assembly 2 are locked by screws 13; the valve body integrates the main live valve 3 and the auxiliary live valve 4 through the spring retaining ring 12, and the auxiliary live valve 4 and the armature 8 are floatingly connected through the hook, which is combined into a step-by-step Direct acting form; the valve body and the electromagnet assembly 1 are connected through the outer nut 7, and the gasket 6 is used for static sealing;

[0020] In the power-off state, the auxiliary valve 4 and the main valve 3 are all closed and sealed. When energized, the coil in the electromagnet assembly 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com