Multi-feature fusion method

A technology of multi-feature fusion and calculation method, applied in the field of multi-feature fusion, it can solve the problems of large influence of subjective experience, lack of universality, and inaccurate selection of features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

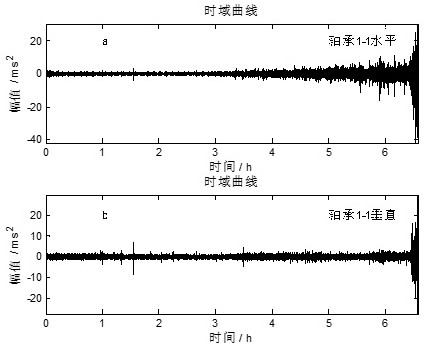

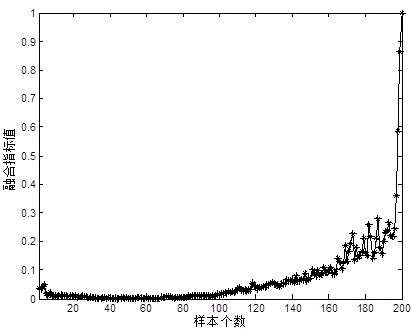

[0093] The experimental data of the IEEE PHM 2012 Data Challenge is used to verify the effect of the proposed method. Since the horizontal and vertical signals of rolling bearings have similar trends in the time domain, the vibration signals of the rolling bearing 1-1 horizontal direction in the IEEE PHM 2012 data set were selected for experiments. The time domain waveforms are shown in image 3 shown. Firstly, the multi-dimensional features of the time domain, frequency domain and frequency domain are extracted, as shown in Table 1-Table 3, and 200 samples in the complete cycle are uniformly selected for analysis in the experiment.

[0094] Table 1 Time domain characteristics

[0095]

[0096] Table 2 Frequency domain characteristics

[0097]

[0098] Table 3 Time-Frequency Domain Characteristics

[0099]

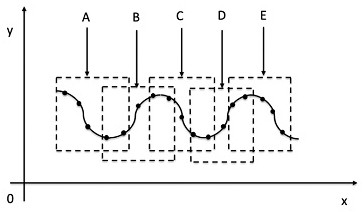

[0100] After extracting the 40-dimensional features of the vibration signal of the rolling bearing, use the similarity analysis based on the Hausdorff distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com