Immersion nozzle

A technology of nozzles and protruding parts, which is applied in the direction of manufacturing tools, casting molten material containers, casting equipment, etc., and can solve the problems of large changes in the liquid level in the mold and large changes in the discharge flow of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

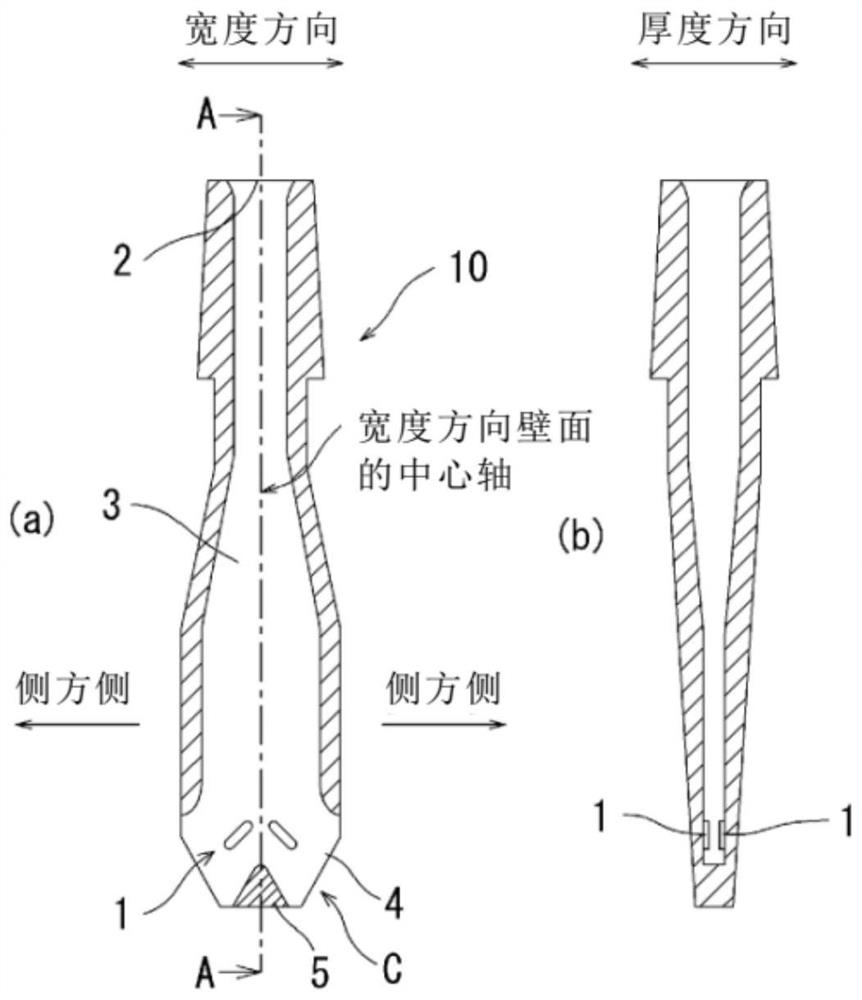

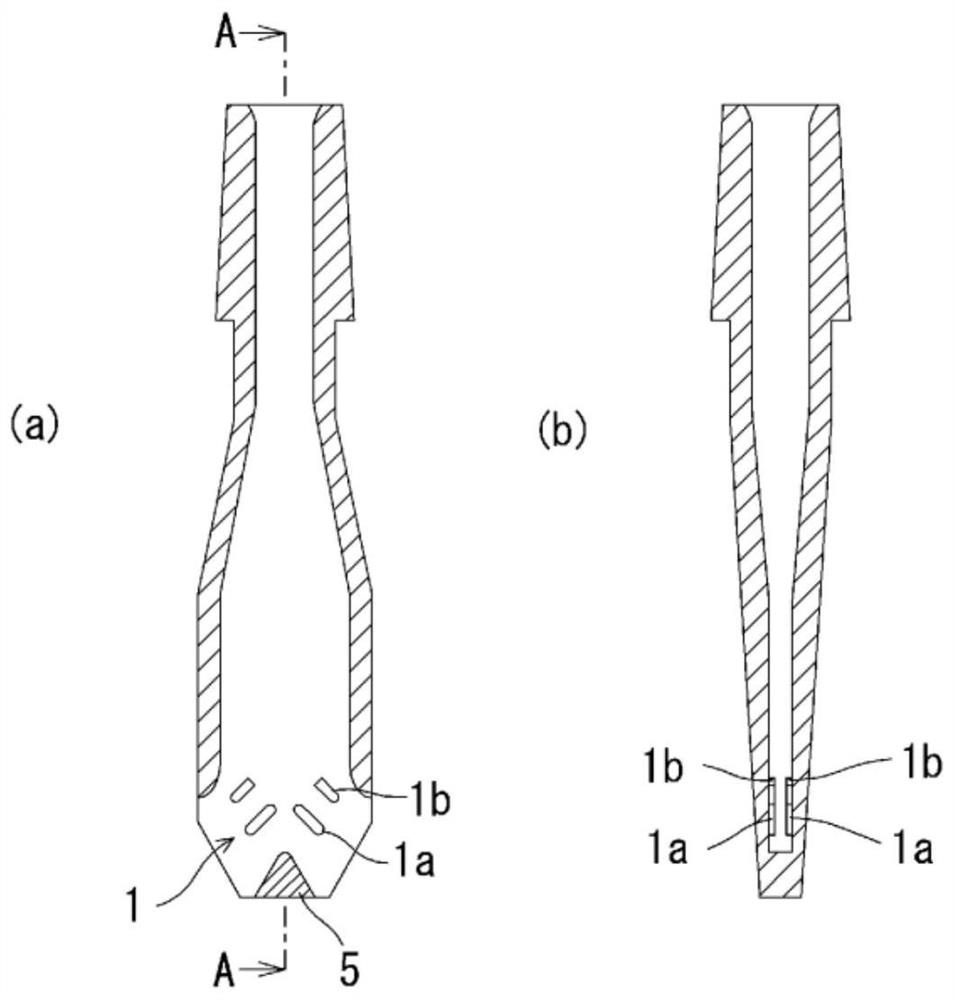

[0077] Embodiment A is water model experiment result, for figure 2 The second aspect of the present invention shown and Figure 4 The submerged nozzle according to the fourth aspect of the present invention shown has the protruding length (total length of a pair of symmetrical protruding parts) Ts, The ratio of Tp to the thickness of the inner hole of the submerged nozzle (length in the short side direction) Tn Ts / Tn, Tp / Tn and the degree of change in the liquid level in the mold (the drift index in the mold and the height of the change in the liquid level in the mold) relationship, the figure 2 The second aspect of the present invention shown is that two layers of axially-symmetrical and plane-symmetrical side protrusions 1a, 1b are provided as protrusions, and no central protrusion is provided between the lower side protrusions 1a, 1a. The shape of the part, the Figure 4 In the fourth aspect of the present invention shown, two layers of axially-symmetrical and plane-sy...

Embodiment B

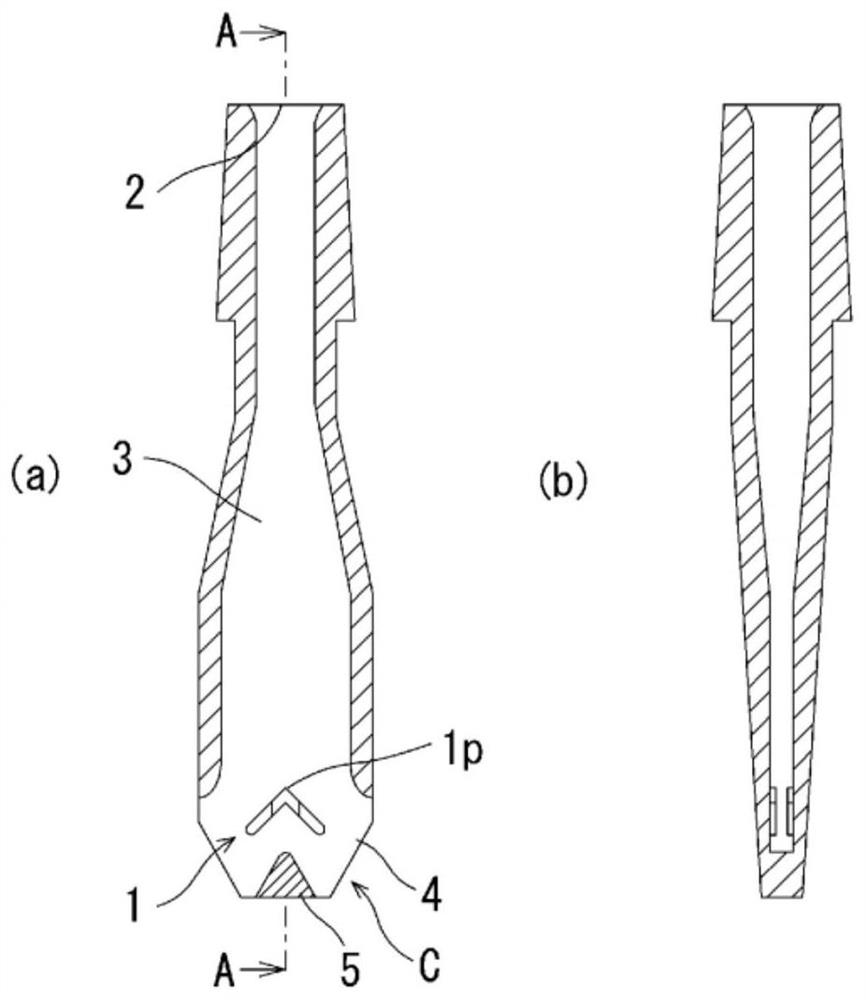

[0113] Embodiment B is water model experiment result, shows that there is Figure 4 In the fourth form of the present invention shown, the upper end faces of the lower lateral protrusion 1a and the central protrusion 1p are formed as follows: Figure 9 The degree of change in the liquid level in the mold when the shape shown is in the direction of the center of the inner hole and the plane is inclined downward.

[0114] Here, the Ts / Tn ratio of the lower lateral protrusions=0.74, the Tp / Tn ratio of the central protrusions=0.18, and the inclination angle of the lower lateral protrusions and central protrusions toward the inner hole ( Figure 9 The case where θ) is 0 degrees (horizontal) is compared with the case of 45 degrees. Other conditions are identical with embodiment A.

[0115] Figure 19 Show the result. Figure 19 The vertical axis of is the value obtained by averaging the maximum liquid level change values Sw (mm) in the left and right directions of the discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com