Production line ceramic shock absorber used during ceramic manufacturing

A production line and shock absorber technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems that the auxiliary buffer structure cannot be organically combined with the disassembly and assembly of buffer parts, and achieve the effect of improving the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

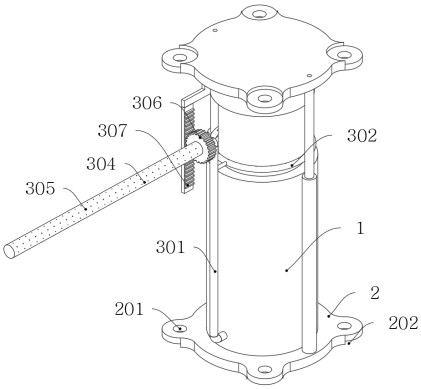

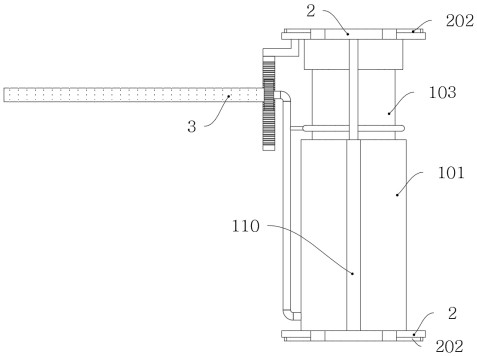

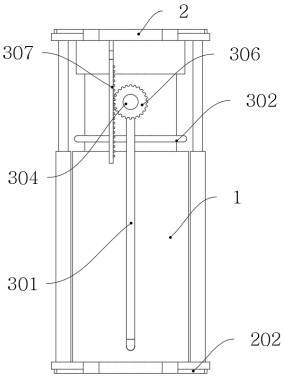

[0060] as attached figure 1 to attach Figure 8 Shown:

[0061] The invention provides a ceramic shock absorber for a production line when making ceramics, which includes a shock absorber main body 1;

[0062] The shock absorption main body 1 is composed of a sleeve 101, a stopper 102, a ceramic cylinder 103, a cylindrical rod 104, a baffle 105, a lock nut 106, a limit seat 107, an elastic block 108 and an elastic member 109;

[0063] There are two fixed seats 2, and there are two fixed seats 2, and the two fixed seats 2 are installed on the shock-absorbing main body 1;

[0064] Auxiliary structure 3. The auxiliary structure 3 is installed on the shock-absorbing main body 1.

[0065] Reference as Figure 4 , the shock absorption main body 1 includes:

[0066] The sleeve 101, the sleeve 101 is a cylindrical barrel structure, and a stopper 102 is welded in the sleeve 101;

[0067] A ceramic cylinder 103, the ceramic cylinder 103 is a cylindrical barrel structure, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com