Knitting process of environment-friendly breathable jacquard fabric

An environmentally friendly and fabric technology, applied in weft knitting, knitting, decorative textiles, etc., can solve problems such as unsatisfactory, achieve the effect of good sweat absorption and quick drying, and avoid snagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

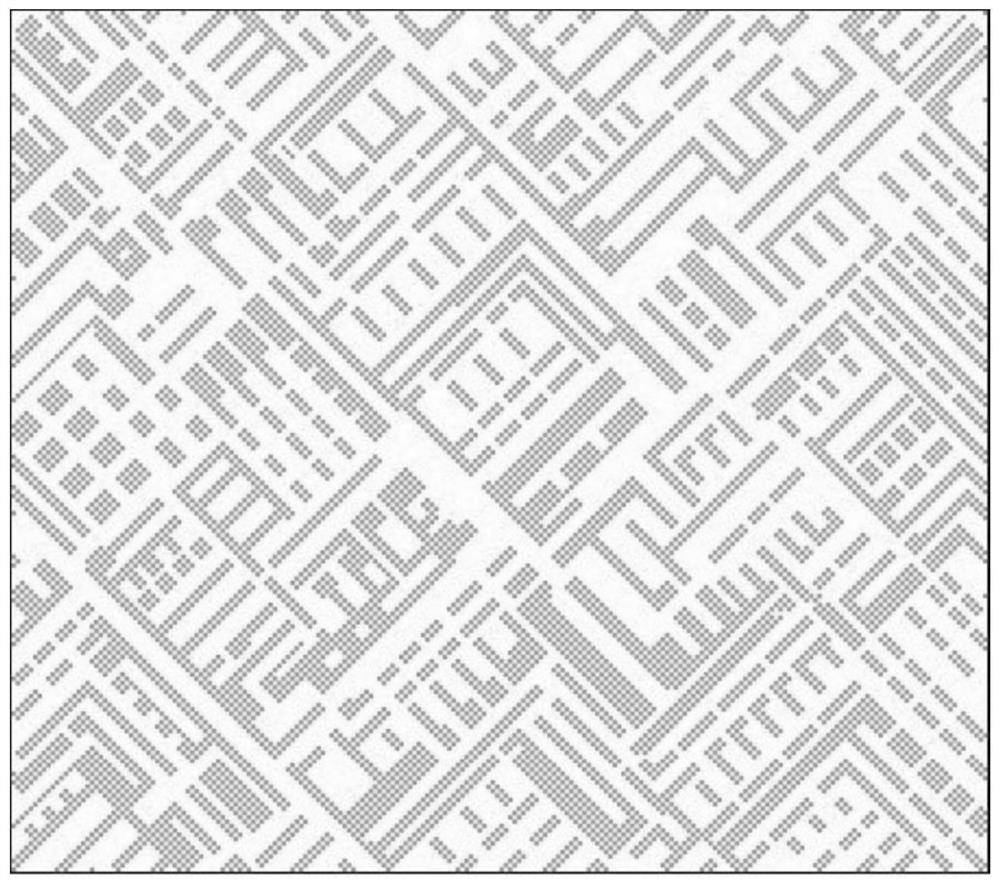

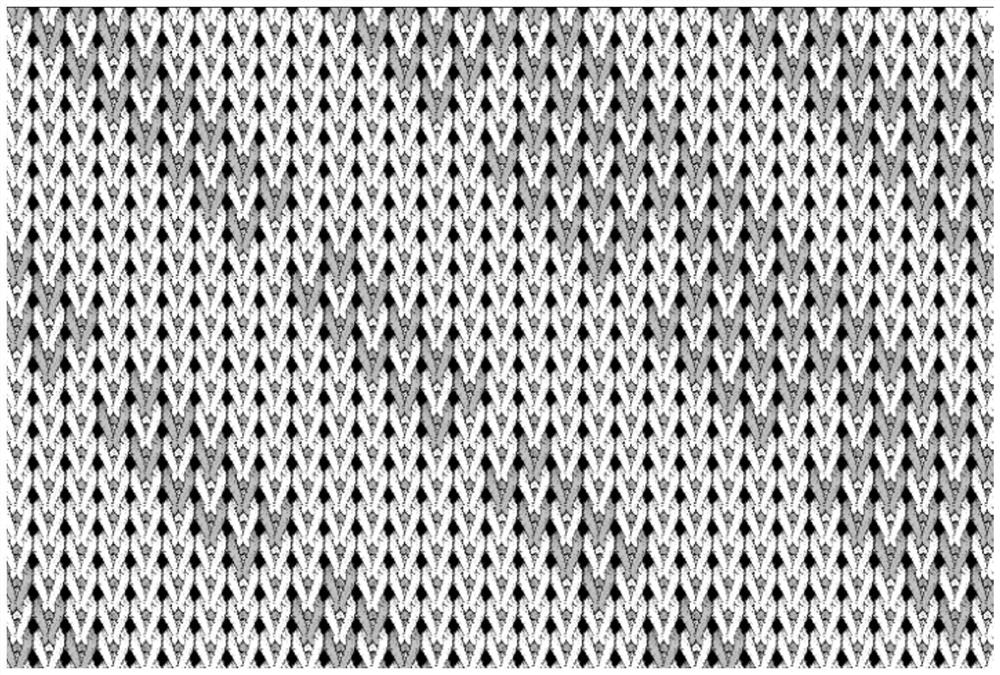

[0015] A weaving process for environment-friendly air-permeable jacquard fabrics. The knitting equipment is a large circular knitting machine for single-sided weft knitting. The knitting road and the jacquard road knit one loop row every two roads as a basic unit, and the needles of the jacquard road are arranged according to the pattern. out of the needle to make the fabric appear jacquard effect (such as figure 1 shown), the specific weaving steps are as follows:

[0016] The first road is the knitting road. All the needles form a loop to participate in the weaving. The GRS-certified Shanghai Yuanfang 84dtex / 36F recycled polyester filament is used. The thread length is 310mm / 100 needles, which has good water absorption and quick-drying performance;

[0017] The second road is the jacquard road. The needles are produced according to the pattern design of the jacquard. The needles corresponding to the jacquard parts are set as floating threads. The quality-controllable, safe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com