Support capable of adjusting elevation

A support and elevation technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of high-speed rail bridge support elevation adjustment and self-locking, and achieve the effect of high self-locking reliability and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

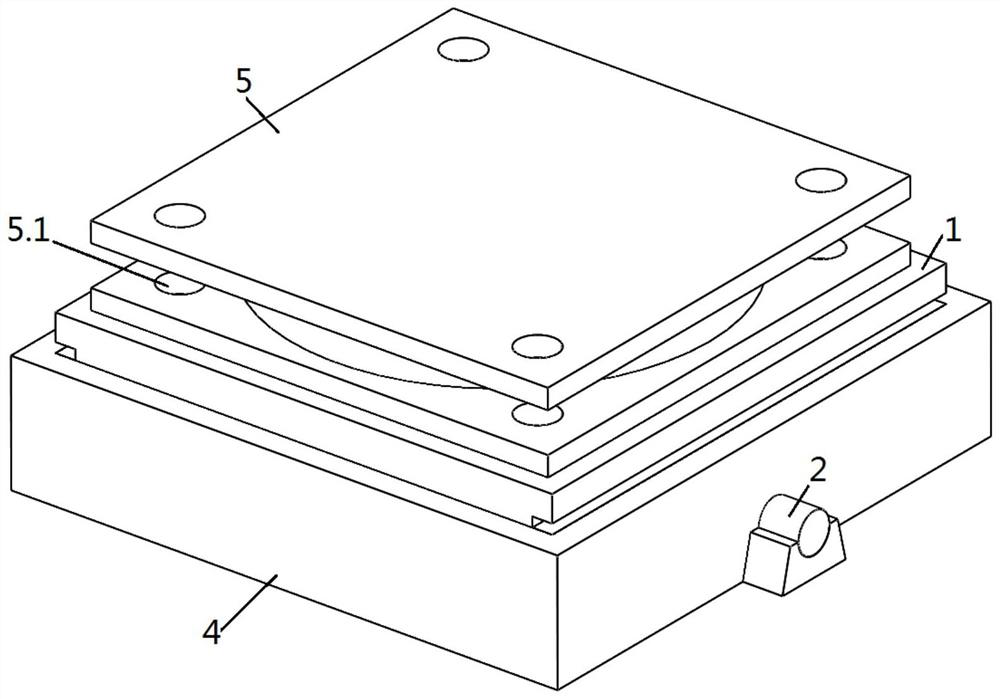

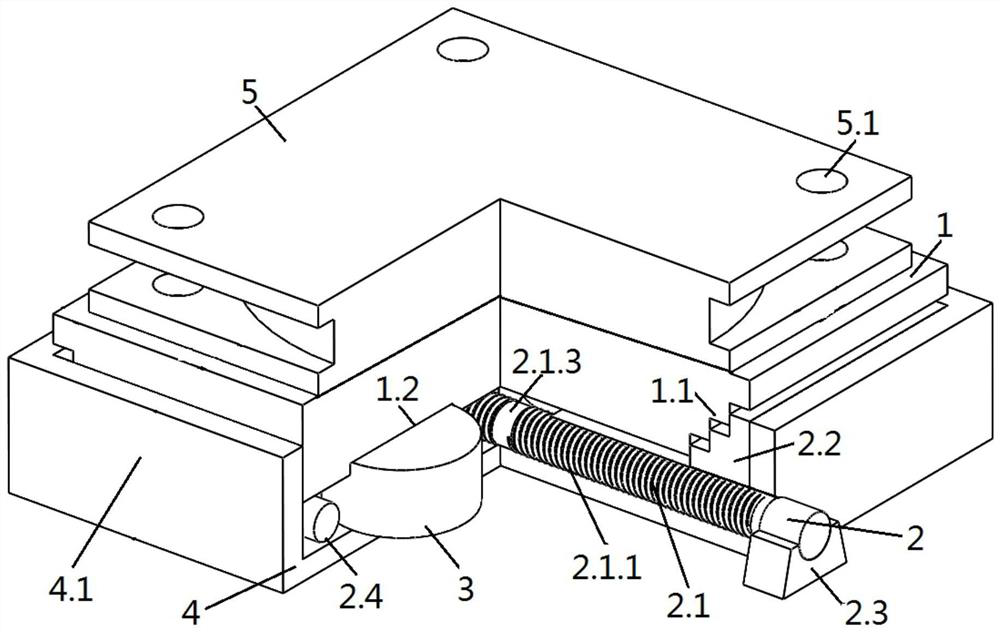

[0041] See Figures 1 to 10 A support for adjusting elevation, this embodiment is applied to the elevation adjustment and self-locking of the bridge support.

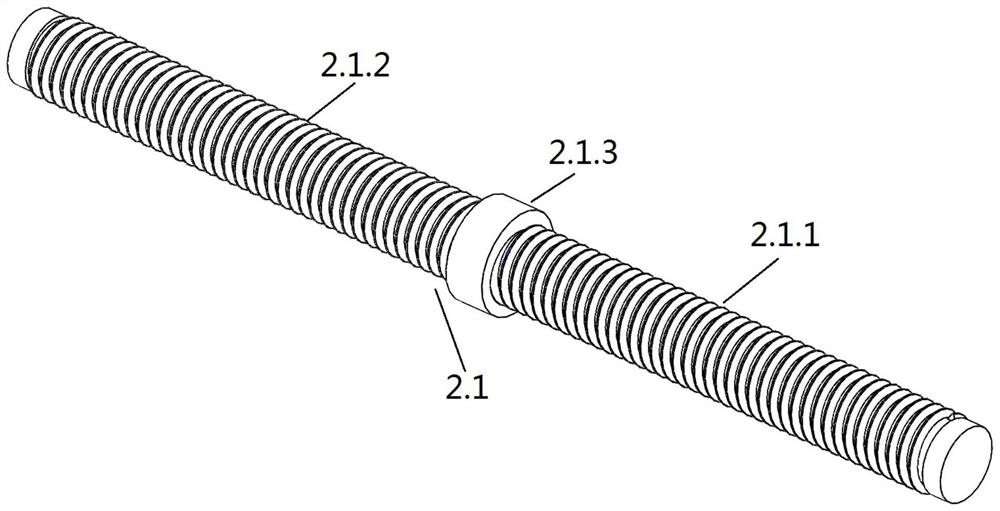

[0042] An adjustment element, including upper pedal 1, self-locking regulating mechanism 2, top rising mechanism 3, and next seat 4; the self-locking regulating mechanism 2 and the top rising mechanism 3 are all located in the upper pedestal 1 and said There is between the next platform 4; the bottom portion of the upper pedal 1 is provided with a fixed step portion 1.1, the self-locking regulating mechanism 2 including adjustment rod 2.1 and a movable step ladder 2.2 in conjunction with the fixed step portion 1.1; the active step Block 2.2 slides on the adjustment lever 2.1. When it is necessary to increase the elevation of the upper pedal 1, the top seat 1 is riser to the set position through the top rod 2.1 to adjust the position of the movable step 1.1, the stepped surface and activity step ladder of the fixed step porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com