Three-way sealing ball valve

A technology for sealing ball valves and ball valves, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problem of low stability of switching valve passages, achieve the effects of reducing heat, avoiding twisting damage, and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

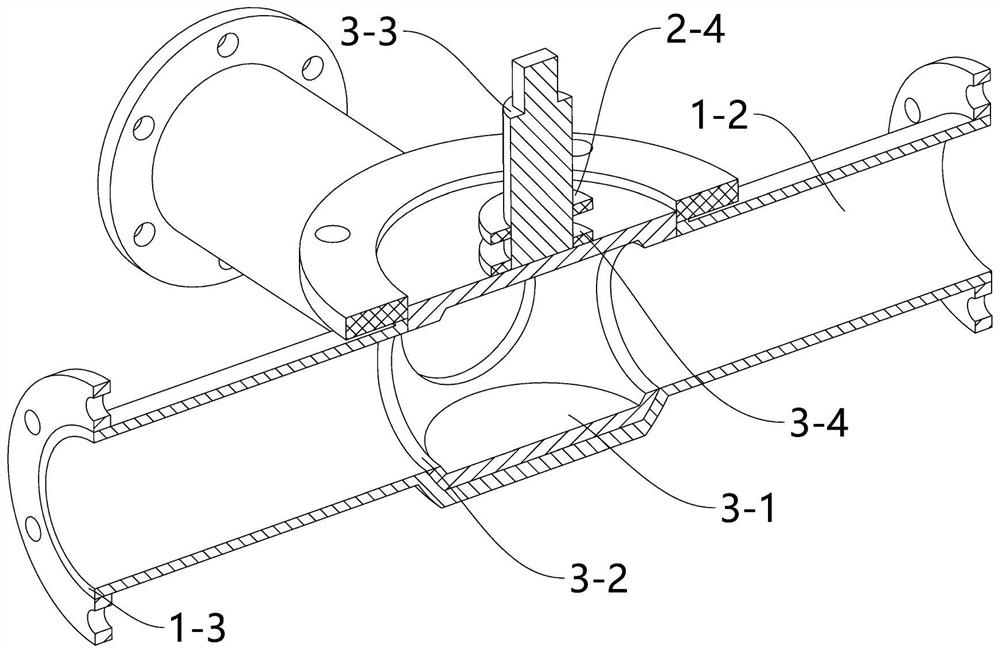

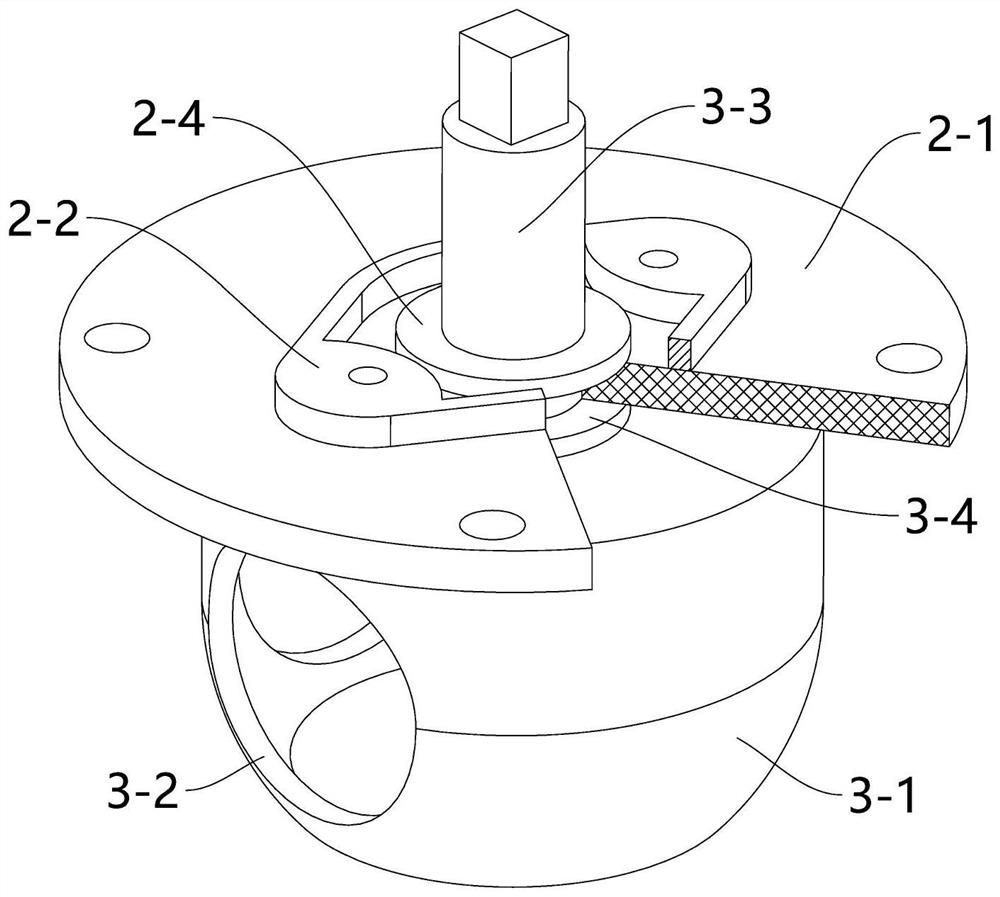

[0059] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

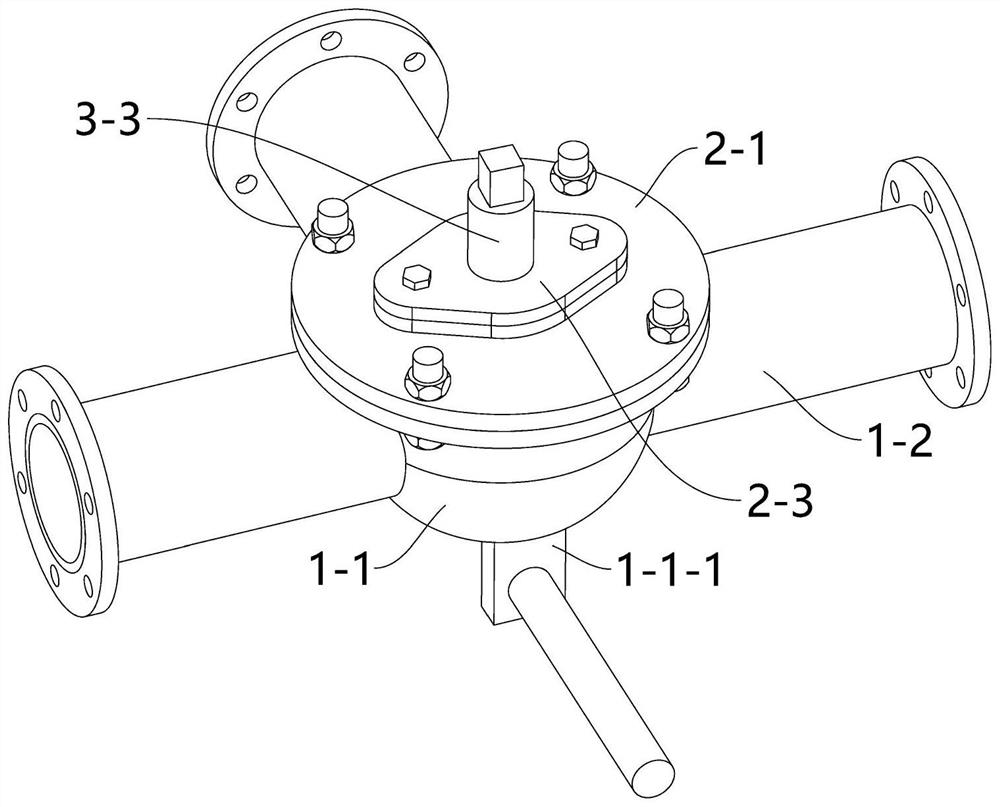

[0060] Refer below figure 1 To illustrate:

[0061] When the operator holds the valve stem 3-3 tightly, the valve stem 3-3 is manipulated to rotate around the axis of the ball valve spool 3-1. At this time, the ball valve spool 3-1 exerts an Lateral force, so that the housing 1-1 has a tendency to rotate together with the valve stem 3-3. In this way, it will cause twisting damage to the pipeline connected with the three-way ball valve. The hidden danger of leakage of the flange at the connecting pipe of the ball valve;

[0062] Thus, a balance arm 1-1-1 is provided, and the balance arm 1-1-1 and the valve stem 3-3 are respectively arranged at the two ends of the three-way ball valve. When turning the valve stem 3-3, the other hand holds The balance arm 1-1-1, thereby reducing the impact on the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com