Detector and ultrasonic probe structure

A detector and ultrasonic technology, applied in the field of ultrasonic probes, can solve the problems of inability to achieve effective detection, close-range blind spots, etc., and achieve the effect of solving close-range blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

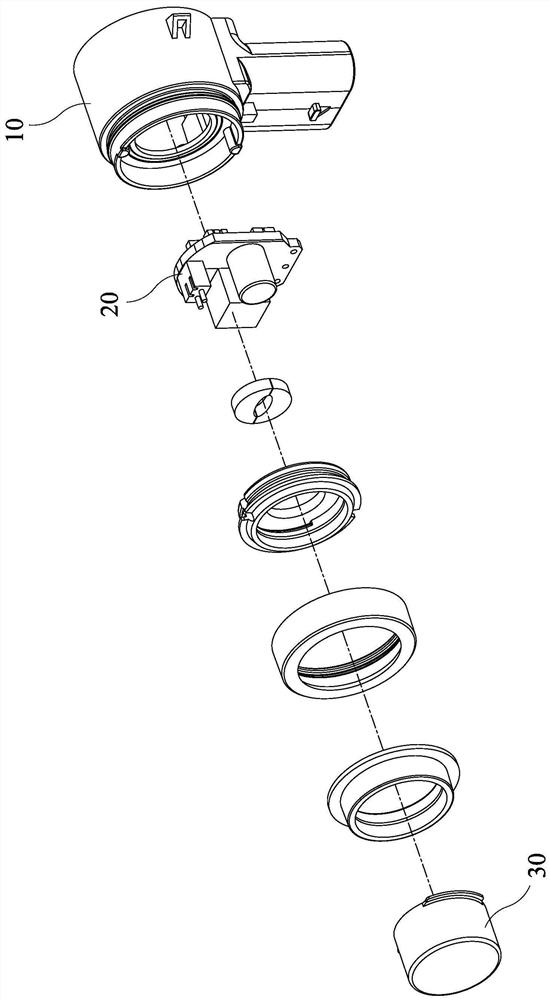

[0034] Aiming at the short-distance blind area problem existing in the existing ultrasonic probe, the present invention proposes an ultrasonic probe that can effectively receive echo signals within the after-vibration time, such as figure 1 As shown, the ultrasonic probe includes a terminal base 10 , a circuit board 20 and a detector 30 , wherein the detector 30 is connected to the circuit board 20 and is arranged on the terminal base 10 together with the circuit board 20 . The circuit board 20 of the ultrasonic probe generates a driving signal, which is sent to the detector 30, and the detector 30 receives the driving signal and emits ultrasonic waves, and at the same time, the detector 30 also receives the echo and converts the echo into electrical The signal is sent to the circuit board 20 for processing. The reason why the ultrasonic probe can transmit and receive ultrasonic waves at the same time is that the present invention improves the detector 30 .

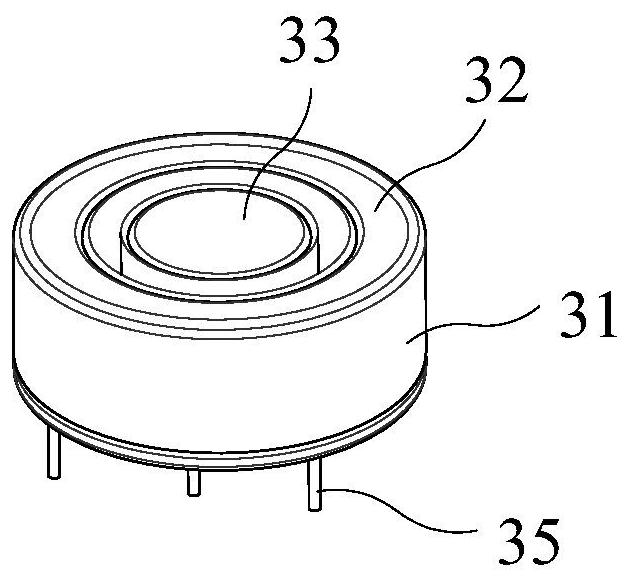

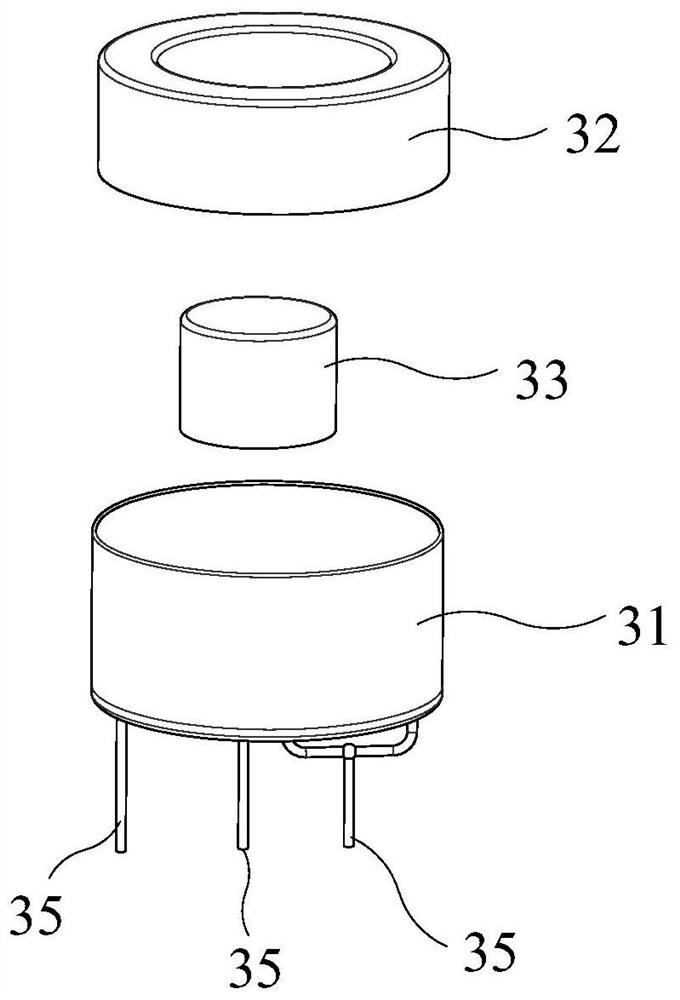

[0035] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com