Novel water spray cleaning equipment of wheel cleaning machine

A technology of water spray cleaning and cleaning machine, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve the problems of low efficiency of washing wheels and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

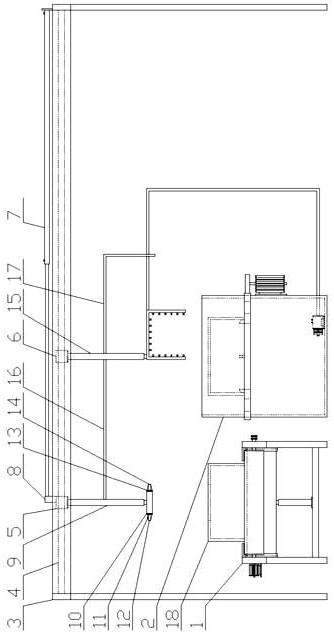

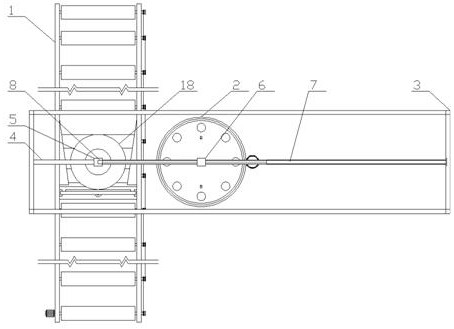

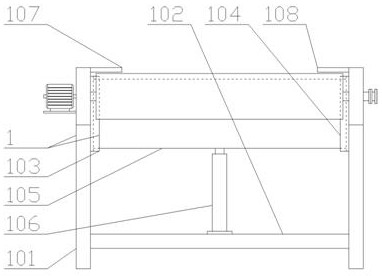

[0020] refer to Figure 1-5 , a new type of water spray cleaning equipment for a wheel washer described in this specific embodiment, including a conveying assembly 1, a cleaning assembly 2, a frame 3, a connecting shaft 4, a sliding sleeve A5, a sliding sleeve B6, a rear flange cylinder A7, Connecting block 8, rear flange cylinder B9, two-way cylinder 10, rear flange cylinder C15, connecting rod 16 and wheels 18, the cleaning assembly 2 is placed on the left side of the conveying assembly 1, and the conveying assembly 1 includes a conveying frame 101 and a support plate 102 , guide groove A103, guide groove B104, baffle plate 105, rear flange cylinder D106, the support plate 102 is fixedly arranged in the middle of the conveying frame 101, and the left and right inner walls of the conveying frame 101 are respectively fixedly provided with guide groove B1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap