Full-automatic numerical control cutting saw for aluminum door and window corner connectors

A fully automatic cutting saw technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc. It can solve the problem of low processing accuracy of corner codes, corner codes that cannot be completely fixed, and angles between corner codes that are difficult to present at 90 degrees. and other issues to achieve the effect of reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

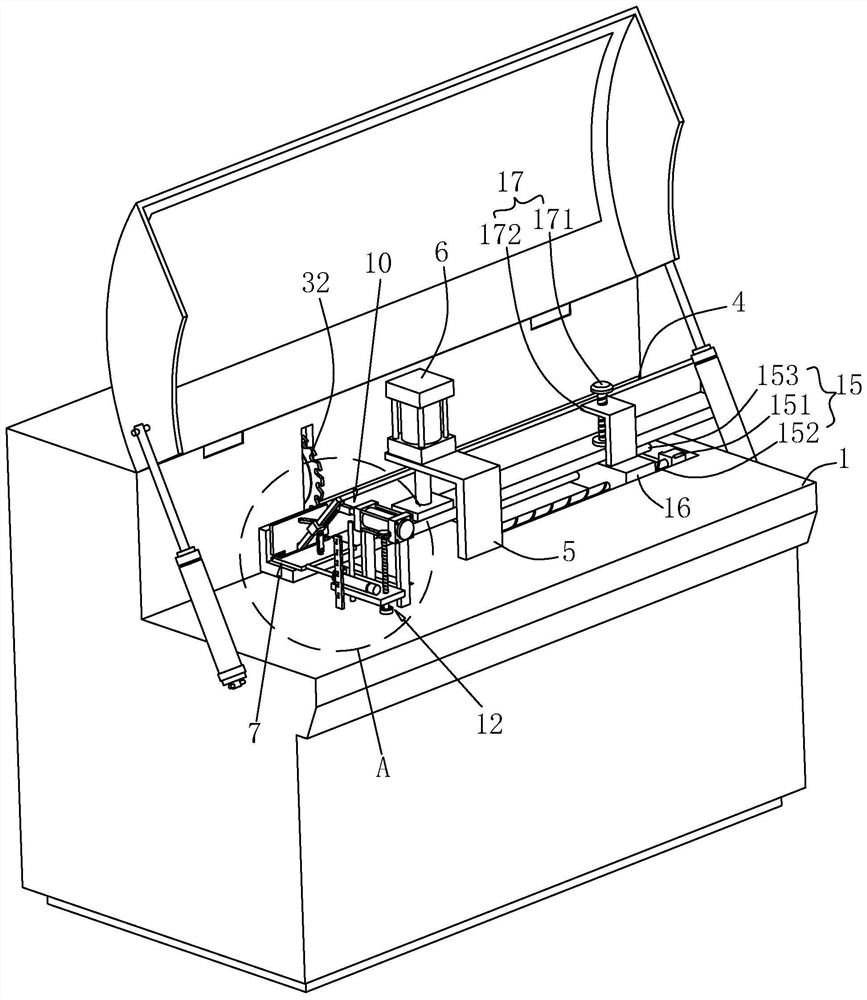

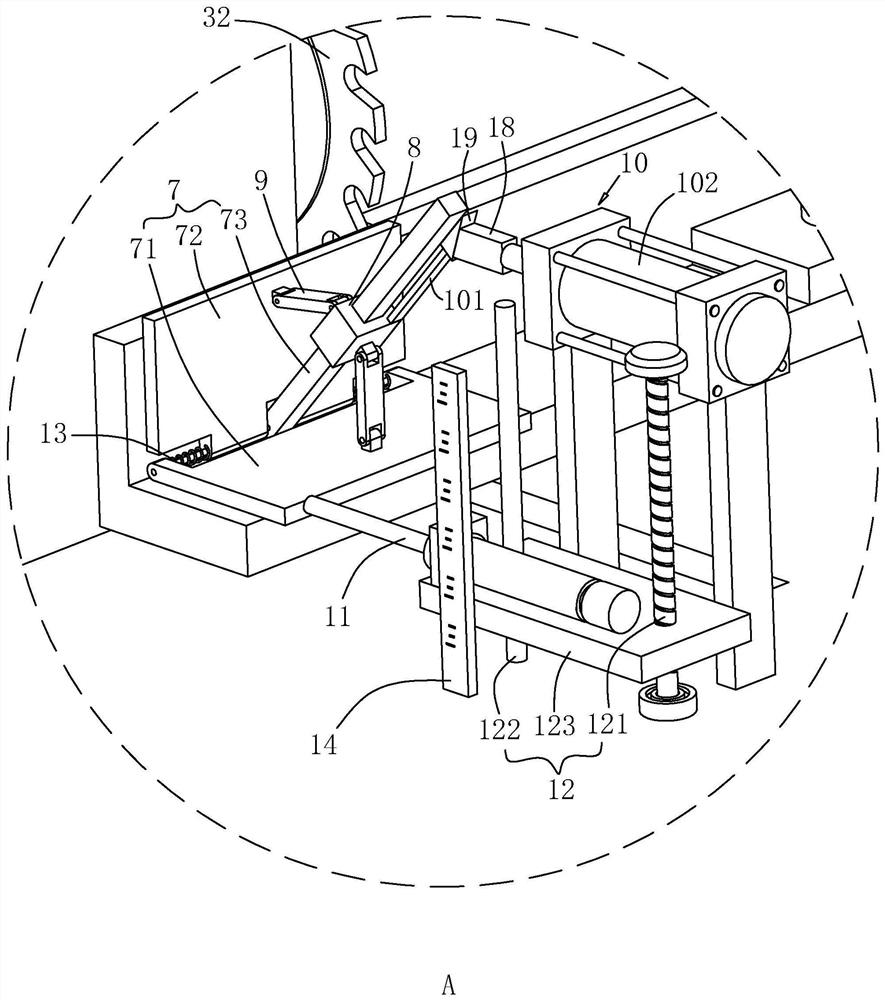

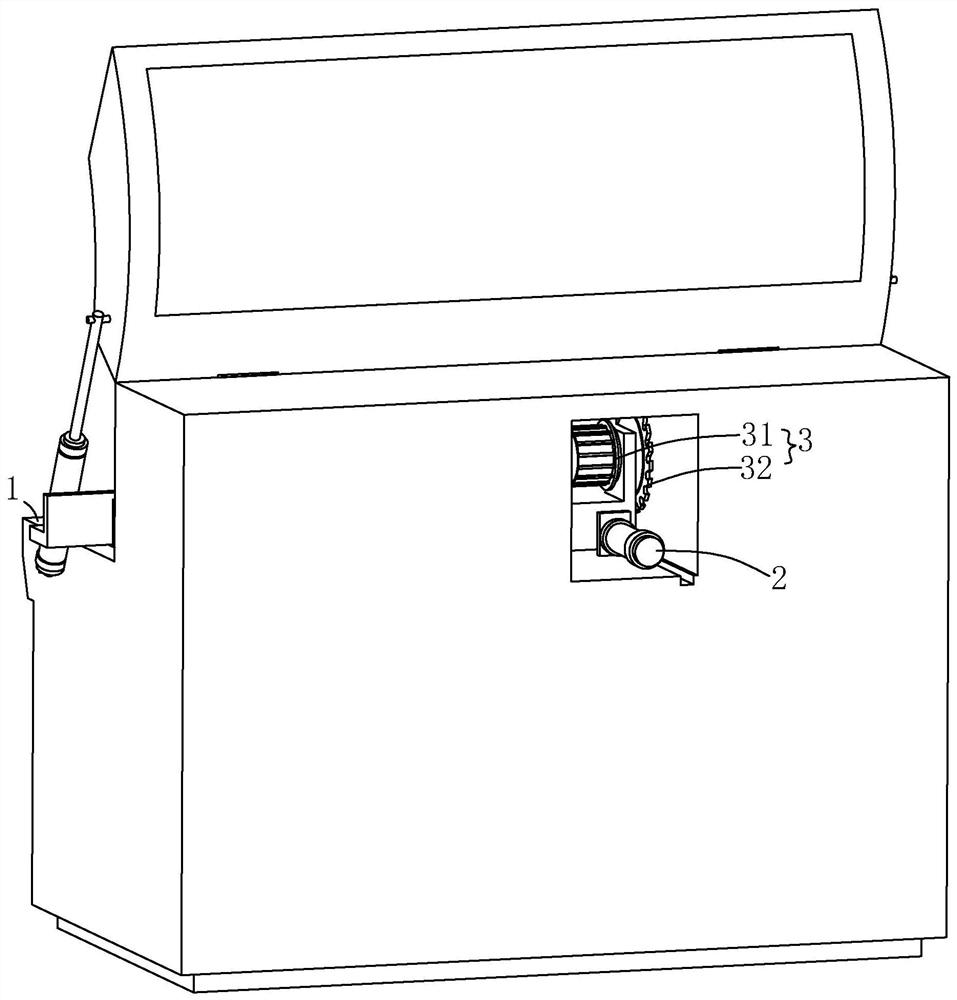

[0029] The following is attached Figure 1-3 The application is described in further detail.

[0030]The embodiment of the present application discloses a fully automatic numerical control cutting saw for aluminum door and window corners. refer to figure 1 , the aluminum door and window corner code automatic numerical control cutting saw includes a workbench 1, and the workbench 1 is welded with a baffle plate 4 for abutting the profile along the feeding direction of the profile. The workbench 1 is vertically welded with a pillar 5. In this embodiment, the pillar 5 is L-shaped. The side of the pillar 5 parallel to the workbench 1 is fixedly connected with a down-press cylinder 6 by bolts. The down-press cylinder 6 is connected to the workbench 1. The upper surface is parallel and used to abut against the profile. The workbench 1 is provided with a feeding device 15 for pushing profiles along its length direction, and the feeding device 15 includes a second motor 151 , a sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap