A Wellhead Gate Valve with an Automatic Replacement Mechanism for a Pressurized Casing

An automatic replacement and casing technology, which is applied in the direction of sliding valves, engine components, wellbore/well valve devices, etc., can solve the problems of difficult casing disassembly and replacement, and achieve easy replacement, improved sealing effect, and guaranteed The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

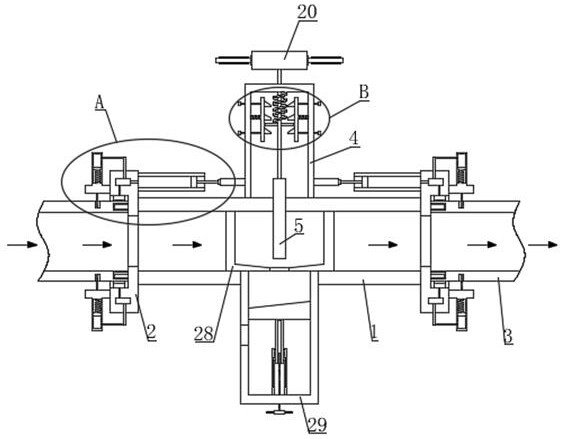

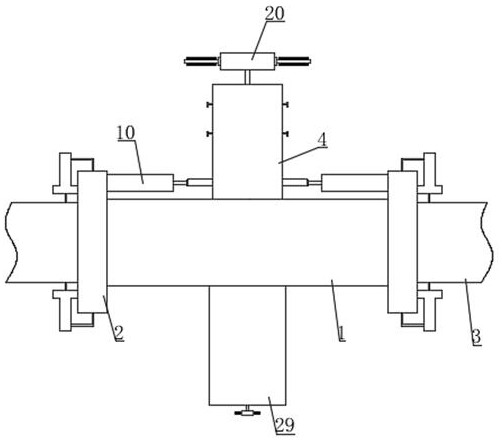

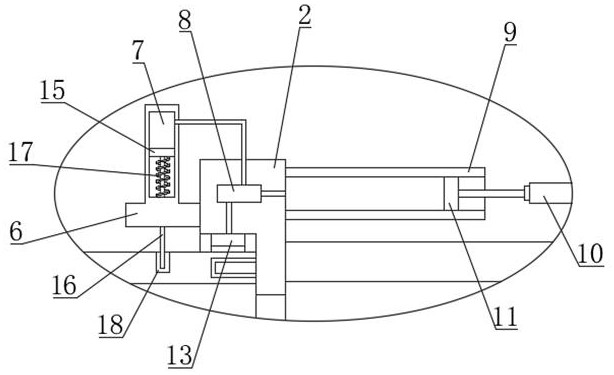

[0035] like Figure 1-8 As shown in the figure, a wellhead gate valve with an automatic replacement mechanism for casing under pressure proposed by the present invention includes a valve body 1, a mounting plate 2, a casing joint 3, an upper valve pipe 4, a valve plate 5 and a lower valve pipe 29, The top of the valve body 1 is fixed with an upper valve pipe 4 by bolts, the bottom of the valve body 1 is fixed with a corresponding lower valve pipe 29 by bolts, and the two ends of the valve body 1 are fixed with a mounting plate 2 by bolts. The joint 3 is connected to the casing, and the mounting plate 2 is provided with a fixed groove 12 and an oil delivery port 14. Oil enters and exits the valve body 1 through the oil delivery ports 14 on both sides. The diameter of the fixed groove 12 is larger than the diameter of the oil delivery port 14. The other end of the pipe joint 3 is inserted into the fixing groove 12 and communicated with the valve body 1 through the oil delivery p...

Embodiment 2

[0041] like Figure 9-10 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a bearing block 34 is slidably arranged in the lower valve pipe 29, and the oil in the valve body 1 enters the oil filter box 30 through the oil inlet 31, and the oil filter hole 32 The oil is filtered, and the filtered debris enters the lower valve pipe 29 through the sewage outlet 33 at the bottom of the oil filter box 30, and the debris falls on the bearing block 34. The bottom of the bearing block 34 is equipped with a lifting mechanism 36. The lifting mechanism 36 For adjusting the height of the bearing block 34, the side wall of the lower valve pipe 29 is provided with a sewage outlet 35. When the bearing block 34 is lowered to the bottom of the sewage outlet 35, the sundries are discharged through the sewage outlet 35, which is convenient for removing the sundries. cleaning, and the upper end of the bearing block 34 is inclined downward in the direction of the sewage ou...

Embodiment 3

[0043] like Figure 6-7 As shown, this embodiment is basically the same as the first embodiment. Preferably, the vertical plate 23 and the upper valve tube 4 are connected by a second spring 26. The second spring 26 is arranged horizontally. A guide rod 25 is installed on the side. The other end of the guide rod 25 passes through the upper valve pipe 4 and is connected to the limit block 27. The guide rod 25 can move in the horizontal direction, and the limit block 27 acts as a limit to avoid the guide rod 25 and the limit block 27. The upper valve tube 4 is disengaged, the upper part of the stopper 24 is an inclined plane, the bottom of the stopper 24 is a horizontal plane, and the inclined plane is inclined downward toward the direction of the rotating rod 21 . When the downward pressure is directly applied to the pressure plate 20, the connecting plate 22 Pressure is applied to the inclined surface of the block 24 below it, and then the block 24 is pushed to move away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com