A battery slurry solid content testing device

A test device and solid content technology, applied in the field of battery slurry solid content test device, can solve the problems of slurry settlement, flocculation, large particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

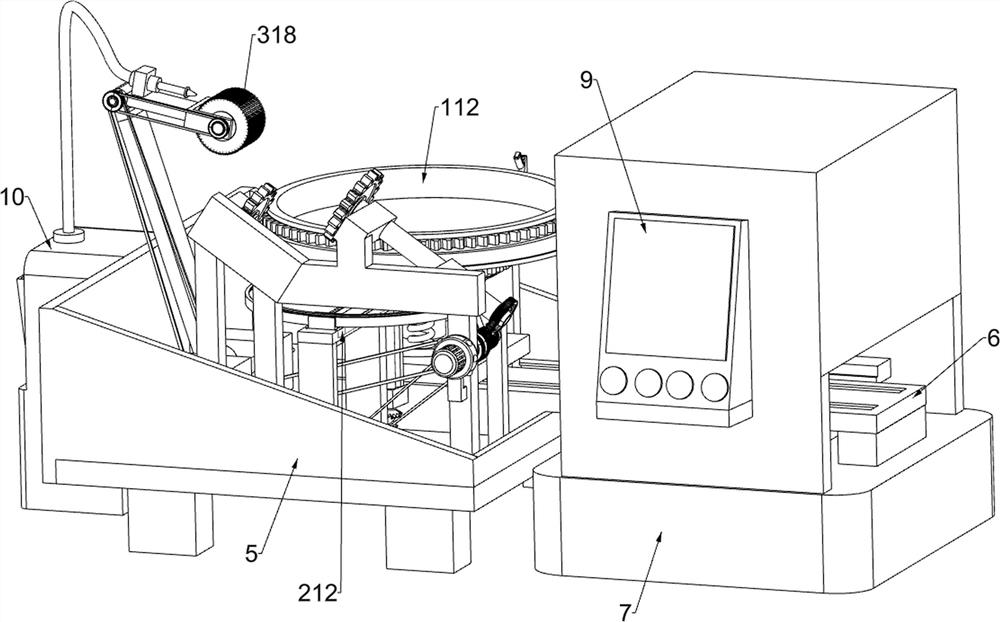

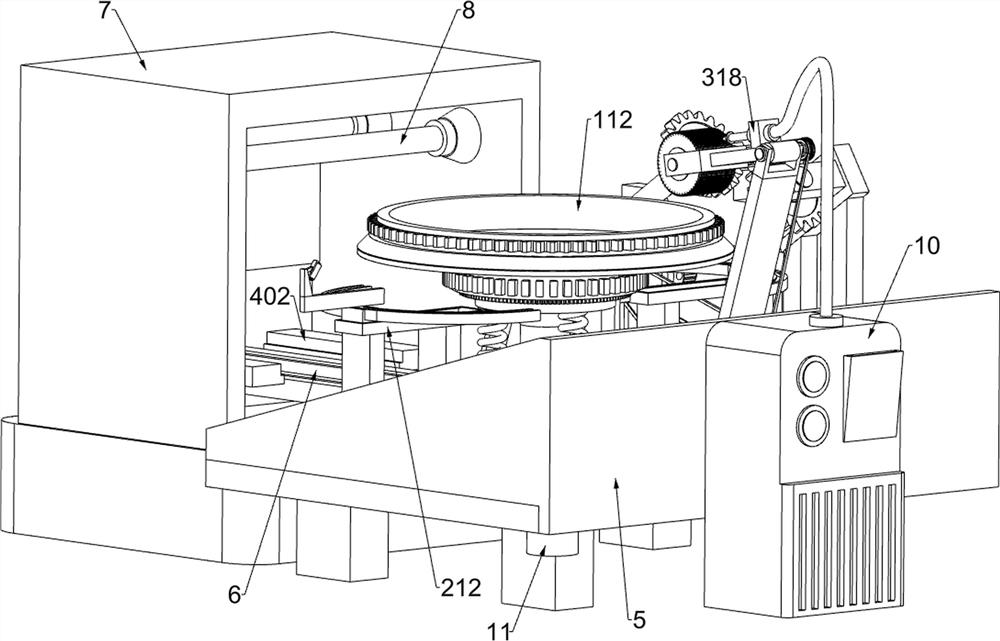

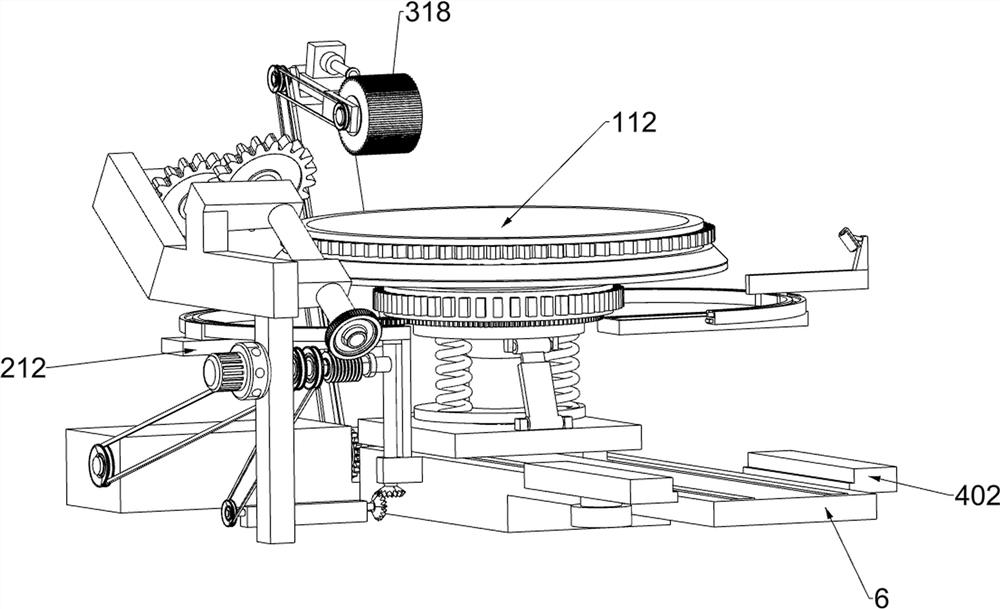

[0033] A battery slurry solid content testing device, such as Figure 1-3 As shown, it includes a slurry loading component, a slurry shaking component, a carrier flushing component, a support platform 5, a long guide rail 6, a weighing mechanism 7, an electric heating rod 8, a console 9, and a shower liquid conveying mechanism 10 And discharge pipe 11; On the right side of support platform 5, weighing mechanism 7 is placed; The left side of long guide rail 6 is fixed on the upper surface of support platform 5; The right side of long guide rail 6 is fixed on weighing mechanism 7 On the inner bottom plate; two sets of electric heating rods 8 are installed on the inner top plate of the weighing mechanism 7; a console 9 is installed on the front of the weighing mechanism 7; A group of drain pipes 11 is installed on the lower left side of the support platform 5; the left side of the surface of the long guide rail 6 is slidably connected with a slurry loading assembly; the slurry lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com