Deodorizing and descaling agent and preparation method thereof

A descaling agent and raw material technology, applied in the field of deodorizing and descaling agent and its preparation, can solve the problems of limitation, sewer corrosion, inability to use washing articles at the same time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

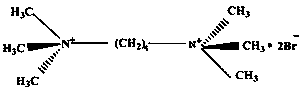

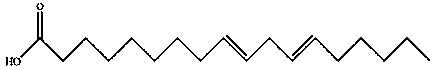

Embodiment 1

[0023] This embodiment provides a deodorizing and descaling agent, which is uniformly mixed with the following raw materials in terms of mass percentage: 30% of butyl hexamethyl ammonium dibromide, 8% of fatty alcohol polyoxyethylene ether sulfate, urethane Lotropine 2%, hydroxymethyl cellulose 5%, 9,12-octadecadienoic acid 8%, the balance is water.

Embodiment 2

[0025] This embodiment provides a deodorizing and descaling agent, which is uniformly mixed with the following raw materials in terms of mass percentage: 10% butyl hexamethyl ammonium dibromide, 4% fatty alcohol polyoxyethylene ether sulfate, urethane Lotropine 1%, hydroxymethyl cellulose 2%, 9,12-octadecadienoic acid 25%, the balance is water

Embodiment 3

[0027] This embodiment provides a deodorizing and descaling agent, which is uniformly mixed with the following raw materials in terms of mass percentage: 8% butyl hexamethyl ammonium dibromide, 1% fatty alcohol polyoxyethylene ether sulfate, urethane Lotropine 0.28%, hydroxymethyl cellulose 0.5%, 9,12-octadecadienoic acid 30%, and the balance is water.

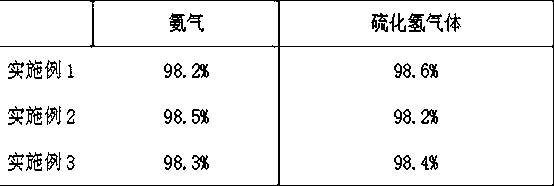

[0028] Performance Characterization

[0029] 1. Descaling effect of deodorizing and descaling agents

[0030] The scale thickness in the sample boiler is 3 mm, and the use temperature is 50°C. After being added to the boiler, the scale is removed in a cycle. The volume ratio of the deodorizing and descaling agent prepared in Examples 1-3 to water is 1 :4 to make a solution, add it to the boiler for circulation, the circulation flow rate is 0.5m / s, wash for 2 hours, the scale removal rate reaches more than 98%, and the corrosion rate reaches 1.506 g / m 2 h. Therefore, the deodorizing and descaling agents prepared in Examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com