Converter station anti-misoperation auxiliary system based on two-dimensional code recognition

An anti-misoperation and auxiliary system technology, applied in the field of converter station operation and maintenance, can solve problems such as incorrect operation steps, and achieve the effect of convenient query and supplementary recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

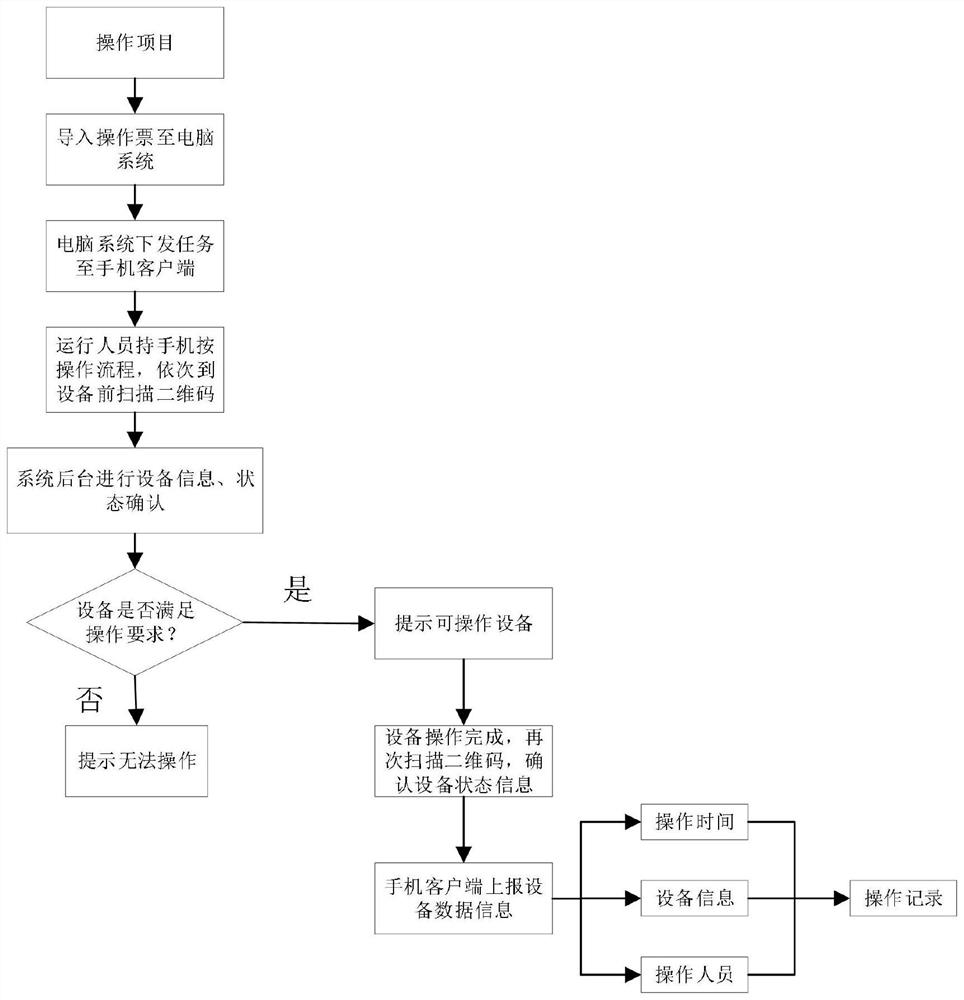

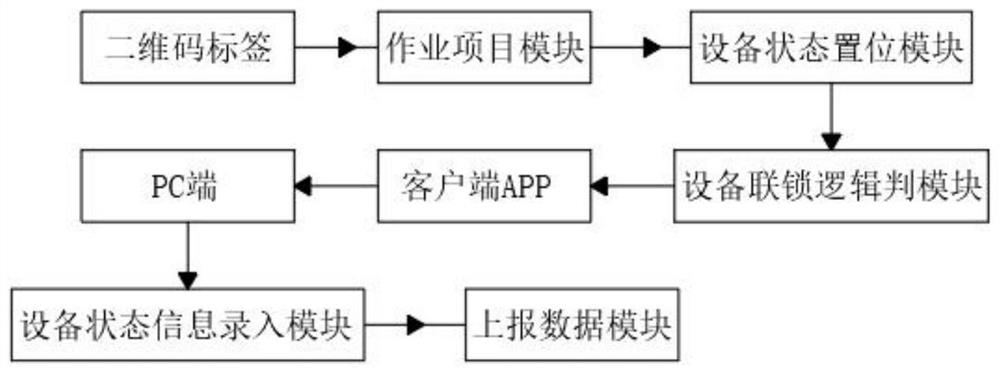

[0027] like figure 1 The shown converter station misoperation prevention auxiliary system based on two-dimensional code identification is characterized in that it includes two-dimensional code labels set on all equipment related to switching operations in the converter station, and is used in conjunction with two-dimensional code labels The job item module, and the device status setting module used in conjunction with the job item module, and the device interlocking logic judgment module used in conjunction with the device status setting module, and the Android and ios used in conjunction with the device interlocking logic judgment module The client APP, and the computer used in conjunction with the client APP, and the field device status setting module information input module used in conjunction with the computer, and the reporting data module used in conjunction with the field device status setting module information input module, report data The information reported by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com