Waste plastic crushing equipment

A technology for crushing equipment and waste plastics, applied in grain processing and other directions, can solve problems such as waste of resources and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

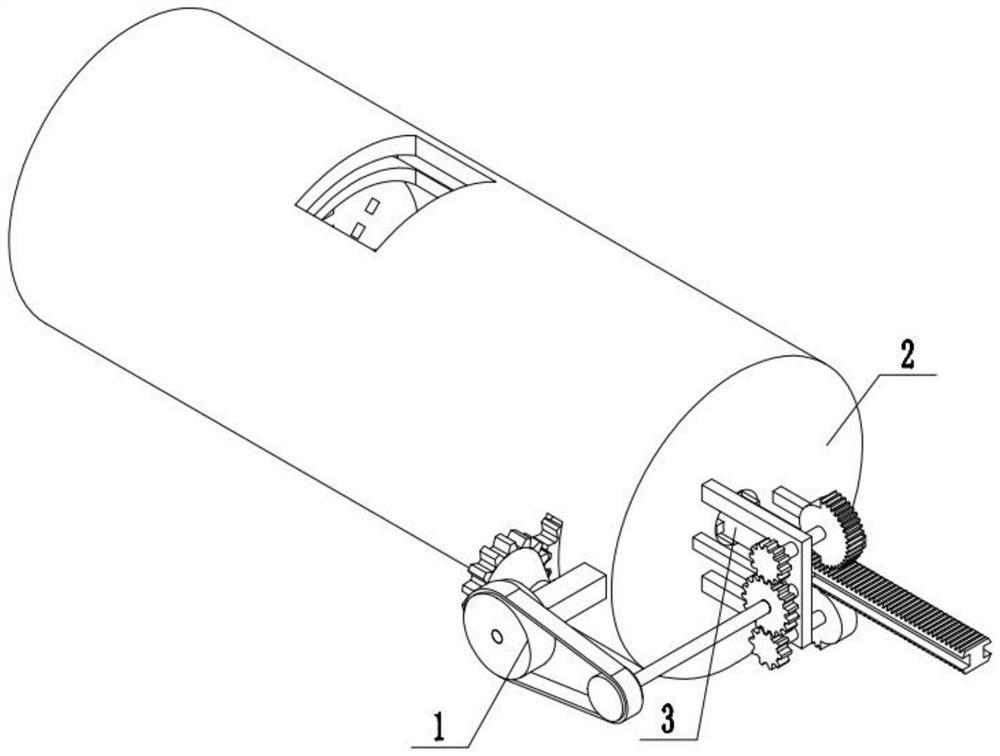

[0028] Combine below figure 1 , 2 . It includes a power transmission device 1, an extrusion installation shell 2, and an extrusion crushing device 3. The power transmission device provides the power for the operation of the entire equipment, and the extrusion installation shell is installed with other devices. The material inside the body is extruded and crushed, and then the function of controlling the feeding and discharging of the extruded crushed material is characterized in that: the power transmission device 1 is installed and fixed on the extrusion installation shell 2, and the extrusion and crushing device 3 is installed and fixed on the Squeeze the inside of the housing 2.

specific Embodiment approach 2

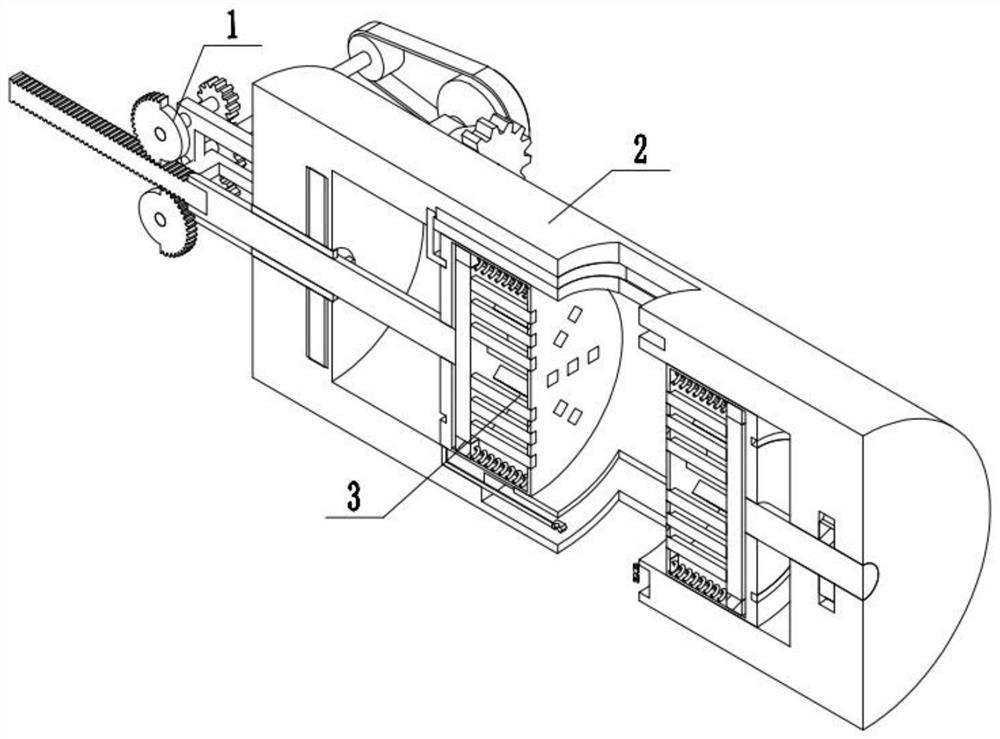

[0030] Combine below figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The power transmission device 1 includes a mounting base 1-1 , driving shaft 1-2, output gear 1-3, transmission shaft one 1-4, gear one 1-5, transmission half gear one 1-6, transmission shaft two 1-7, gear two 1-8, transmission half gear Two 1-9, fixed mounting rail 1-10, mobile double-sided rack 1-11, output pulley 1-12, transmission belt 1-13, mounting seat 1-14, fixed shaft 1-15, bevel tooth surface Transmission pulley 1-16, fixed shaft 1-17, tapered face gear 1-18, the plastics that need to be processed are added to the inside of the mounting shell 2-1 of the extruded mounting shell 2, and then the active drive of the power transmission device 1 Shaft 1-2 rotates under the action of supporting motor, drive shaft 1-2 drives output gear 1-3 to rotate, output gear 1-3 drives gear one 1-5 and gear two 1-8 to rotate, ge...

specific Embodiment approach 3

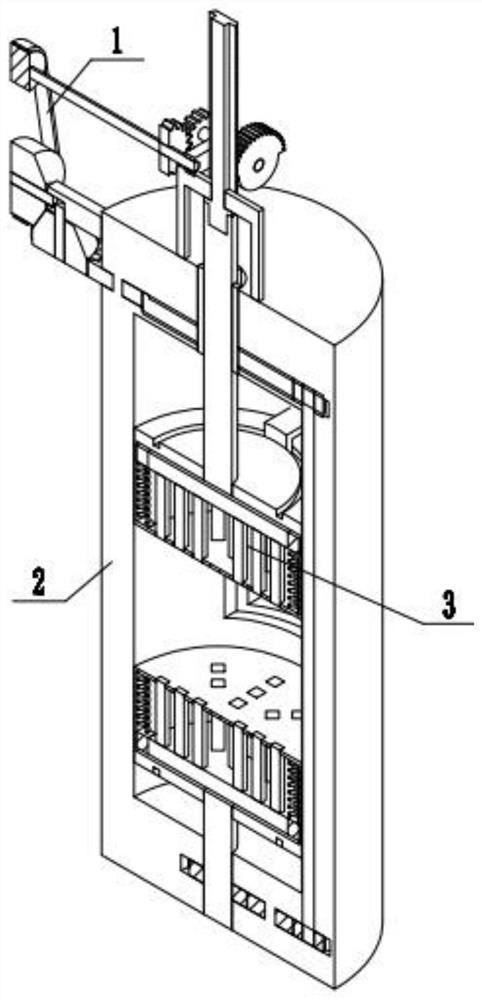

[0032] Combine below figure 1 , 2 . 2-1, material inlet 2-2, material outlet 2-3, installation seat 1-1 is installed and fixed on the installation shell 2-1, fixed installation rail 1-10 is installed and fixed on the installation shell 2-1 , the mounting seat 1-14 is installed and fixed on the mounting shell 2-1, the feeding port 2-2 is set on the mounting shell 2-1, and the discharge port 2-3 is set on the mounting shell 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com