Breathable and moisture-permeable down-proof cloth and weaving method thereof

An anti-feather fabric and moisture-permeable technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of high fabric tightness, hard fabric feel, and low air permeability of anti-feather fabrics, and achieves good feather-proof effect. The effect of wearing down jackets is comfortable and improves the effect of breathability and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

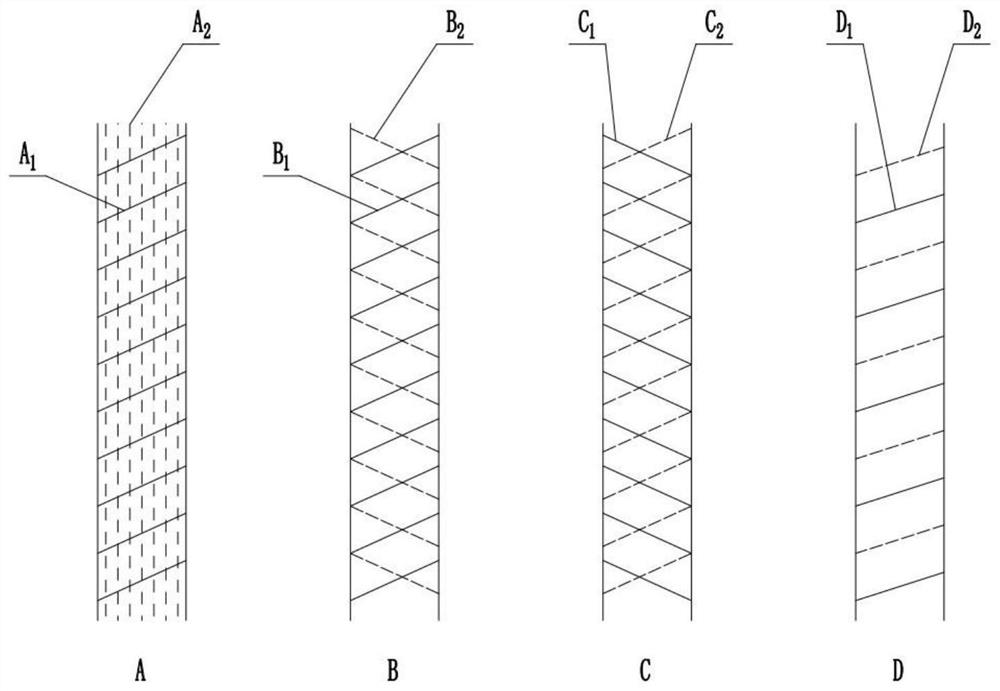

[0059] Such as figure 1 As shown in A, weaving anti-feather cloth with warp and weft yarns with 0 twist:

[0060] In step (1), the warp or weft is twisted 8 pieces / cm in S direction according to the body twist direction.

[0061] In step (2), the yarn and the hydrolyzed polyester filament are combined and twisted, and 8 twists / cm are added in the Z direction.

[0062] In step (3), the ply-twisted yarn is set.

[0063] Step (4), weaving according to technological requirements,

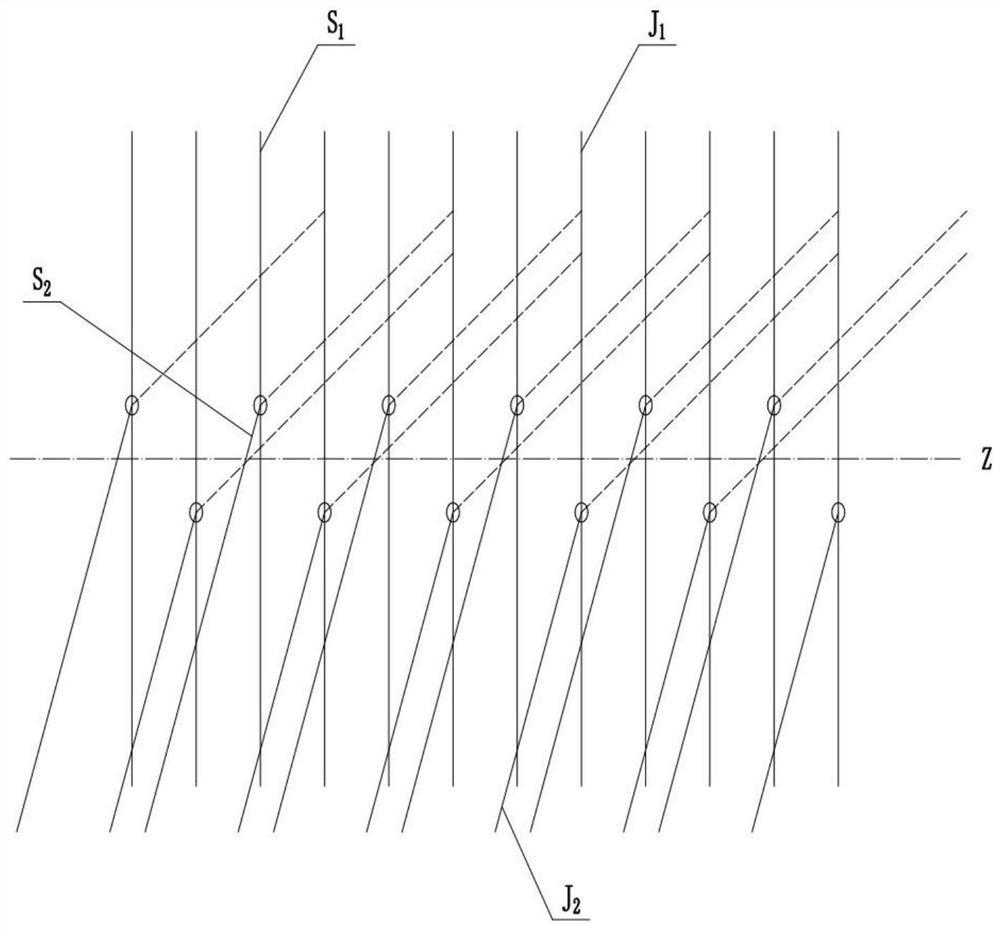

[0064] Step (4-1), arrange the healds 1-2mm above the heald hole and 1-2mm below the heald hole in a ratio of 1:1, and install them on a page of heald frames , arrange and install in sequence, and thread the warp yarns in sequence,

[0065] Step (4-2), the odd warp yarn is set as the tight warp yarn, and the even number warp yarn is the loose warp yarn, and the plain weave is carried out according to the above situation and the weft yarn,

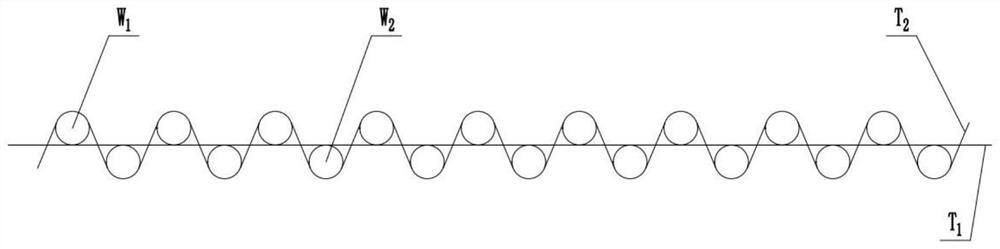

[0066] Step (5), put the woven gray cloth into water 10 ti...

Embodiment 2

[0069] Such as figure 1 As shown in B, weaving anti-feather cloth with warp and weft yarns with 16 twists / cm twist in Z direction:

[0070] In step (1), the warp yarn or weft yarn is twisted in S direction according to the body and 10 twists / cm are added in S direction.

[0071] In step (2), the yarn and the hydrolyzed polyester yarn are combined and twisted, and 26 twists / cm are added in the Z direction.

[0072] In step (3), the ply-twisted yarn is set.

[0073] Step (4), weaving according to technological requirements,

[0074] Step (4-1), arrange the healds 1-2mm above the heald hole and 1-2mm below the heald hole in a ratio of 1:1, and install them on a page of heald frames , arrange and install in sequence, and thread the warp yarns in sequence,

[0075] Step (4-2), the odd warp yarn is set as the tight warp yarn, and the even number warp yarn is the loose warp yarn, according to the above situation and weft yarn one up and one down plain weave,

[0076] Step (5), p...

Embodiment 3

[0079] Such as figure 1 As shown in D, weaving warp and weft yarns have an anti-feather cloth with a twist of 10 pieces / cm in S direction:

[0080] In step (1), the warp yarn or weft yarn is twisted in S direction according to the body and S twisted 2 pieces / cm.

[0081] In step (2), the yarn and the hydrolyzed polyester yarn are combined and twisted, and 8 twists / cm are added in the S direction.

[0082] In step (3), the ply-twisted yarn is set.

[0083] Step (4), weaving according to technological requirements,

[0084] Step (4-1), arrange the healds 1-2mm above the heald hole and 1-2mm below the heald hole in a ratio of 1:1, and install them on a page of heald frames , arrange and install in sequence, and thread the warp yarns in sequence,

[0085] Step (4-2), the odd warp yarn is set as the tight warp yarn, and the even number warp yarn is the loose warp yarn, according to the above situation and weft yarn one up and one down plain weave,

[0086] Step (5), put the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com