A prestressed section steel support pile and its installation method

A technology of supporting piles and prestressing, applied in excavation, sheet pile walls, construction, etc., can solve problems such as cumbersome construction, impact on construction period, and low bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

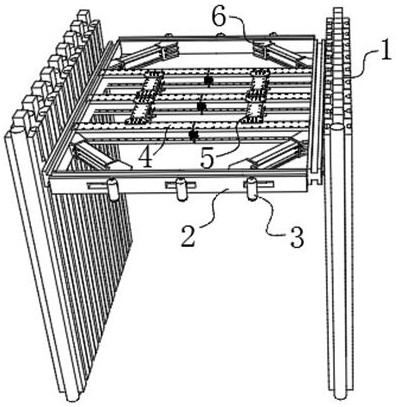

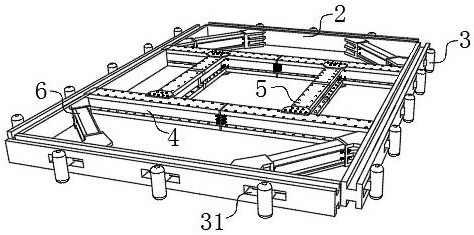

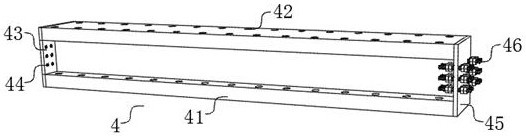

[0032] see Figure 1-7 , the present invention provides the following technical solutions: a prestressed steel support pile, including a support pile 1, one side of the support pile 1 is provided with an H-shaped butt beam 2, and the surface of the H-shaped butt beam 2 is provided with several adjustment mechanisms 3. The inner wall of the H-shaped butt beam 2 is fixedly connected with a number of support mechanisms 4, and the adjacent support mechanisms 4 are fixedly connected with a strengthening mechanism 5, and two adjacent H-shaped butt beams 2 are fixedly connected by a shaping mechanism 6.

[0033] In this embodiment: both ends of the support pile 1 are fixedly connected with clamping blocks 11, the surface and back of the support pile 1 are provided with installation grooves 12, and one side of the support pile 1 is provided with a docking groove 13. The other side of the support pile 1 is fixedly connected with a butt column 14, and the butt column 14 extends from bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com