Double collar for pipeline joint and preparation method of double collar

A technology of pipe joints and double ferrules, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, sleeve/socket connections, etc., which can solve the nuclear-level application requirements of domestic products and have not yet found double-tube lines. joints and other problems to achieve the effect of improving toughness and increasing axial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

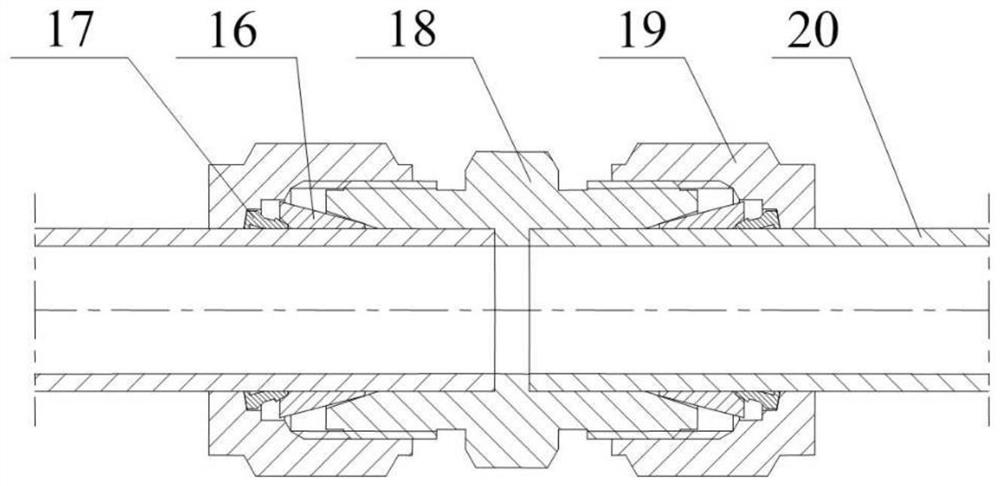

[0041] In order to meet the above test requirements and make the domestic double ferrule joint meet the requirements of nuclear grade use, the applicant determined the specific size range of the double ferrule through continuous exploration and on the basis of the disclosure content of foreign product patents, thus providing a Two ferrules for pipe joints:

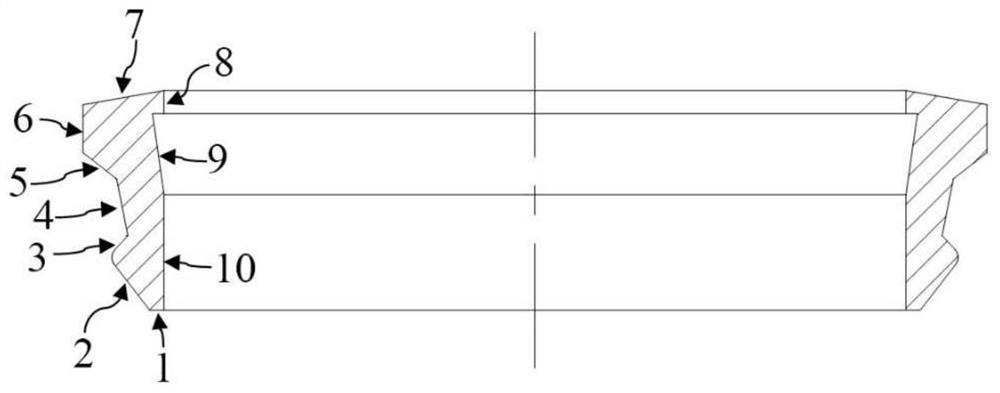

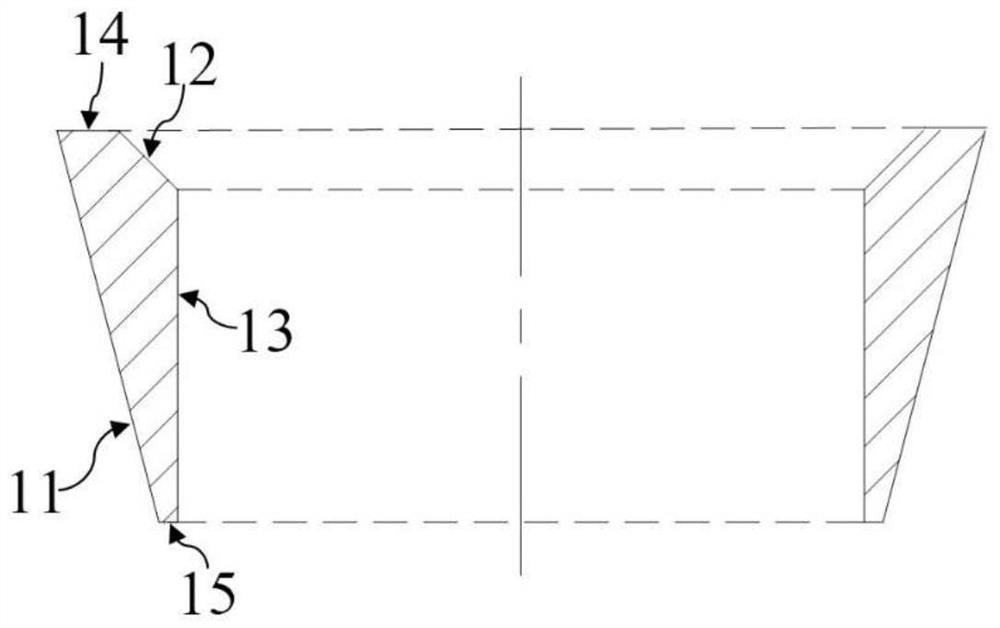

[0042] Such as figure 1 As shown, the cross-section of the rear ferrule is similar to a high-heeled shoe, and its outer wall includes a front section, a middle section, and a back section. 2 The included angle B with the axis is 37.5°, the rear section 6 of the outer wall is parallel to the axis, the middle section of the outer wall includes three sections of outer wall that are recessed toward the axis, the included angle C between the first section of the outer wall 3 and the radial direction is 45°, and the second section of the outer wall 4 The included angle D with the axis is 11°, and the included angle E between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle a | aaaaa | aaaaa |

| Angle a | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com