Equipment state information normalization acquisition method

A technology of equipment status and collection method, applied in the direction of comprehensive factory control, instruments, and comprehensive factory control, etc., can solve the problems of difficult to accurately describe, difficult to realize status collection, increase the workload of software development, etc., to achieve easy monitoring and convenient unified supervision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

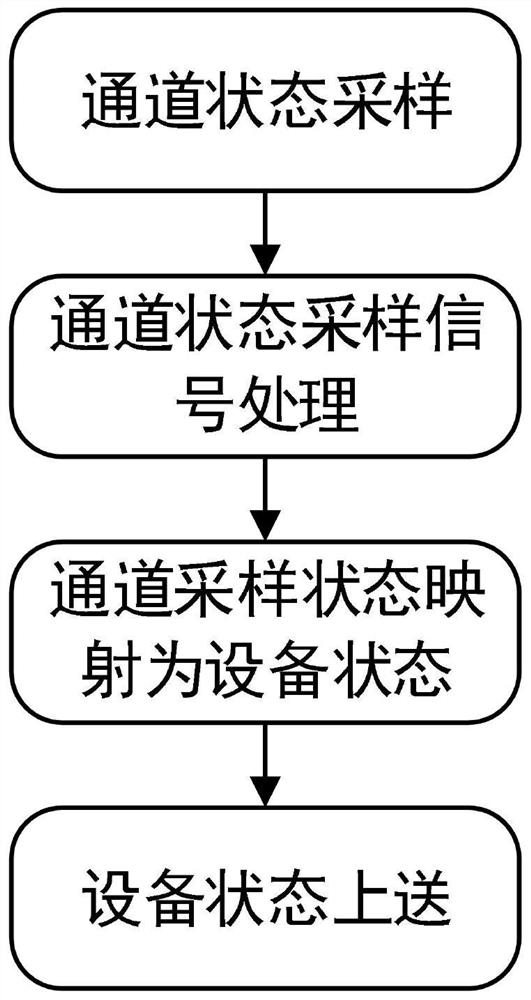

[0026] Embodiment: a method for normalized collection of equipment state information, such as figure 1 shown, including the following steps:

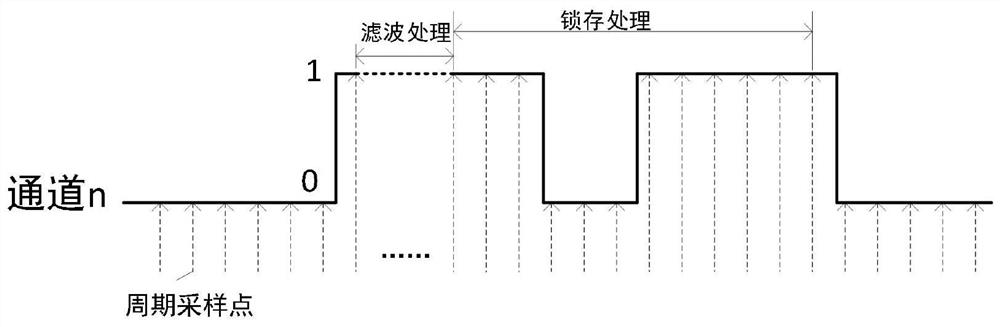

[0027] S1: if figure 2 As shown, the MCU (microcontroller, single-chip microcomputer) periodically collects the state signal of the channel input, that is, collects the state signal of the channel input at an interval of t, and the state signal includes the first signal and the second signal, such as figure 2 The first signal shown in is a "0" signal, and the second signal is a "1" signal.

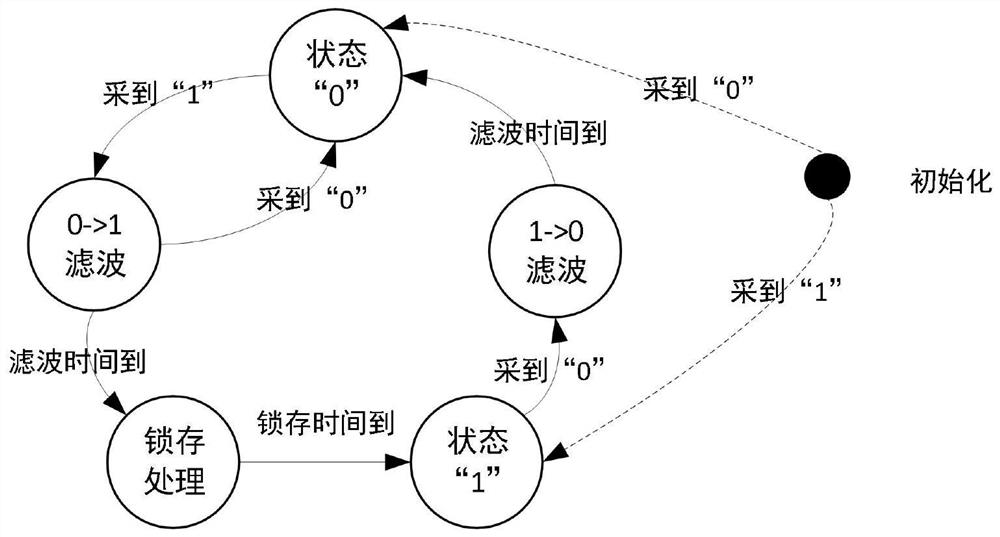

[0028] S2: Initialize the state signal of MUC acquisition channel input, take the first signal as the first state to collect the state signal, take the second signal as the second state as the second signal with the state signal collected; image 3 As shown, the first state is the state "0", and the second state is the state "1". When the "0" signal is collected, it enters the state "0", and when the "1" signal is collected, the state is "1". ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com