A dynamic adjustment system and construction method for main cable lateral movement of suspension bridge

A technology for dynamic adjustment and suspension bridges, applied in suspension bridges, bridges, bridge construction, etc., can solve problems such as poor stability, achieve good stability, ensure safety, and improve ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

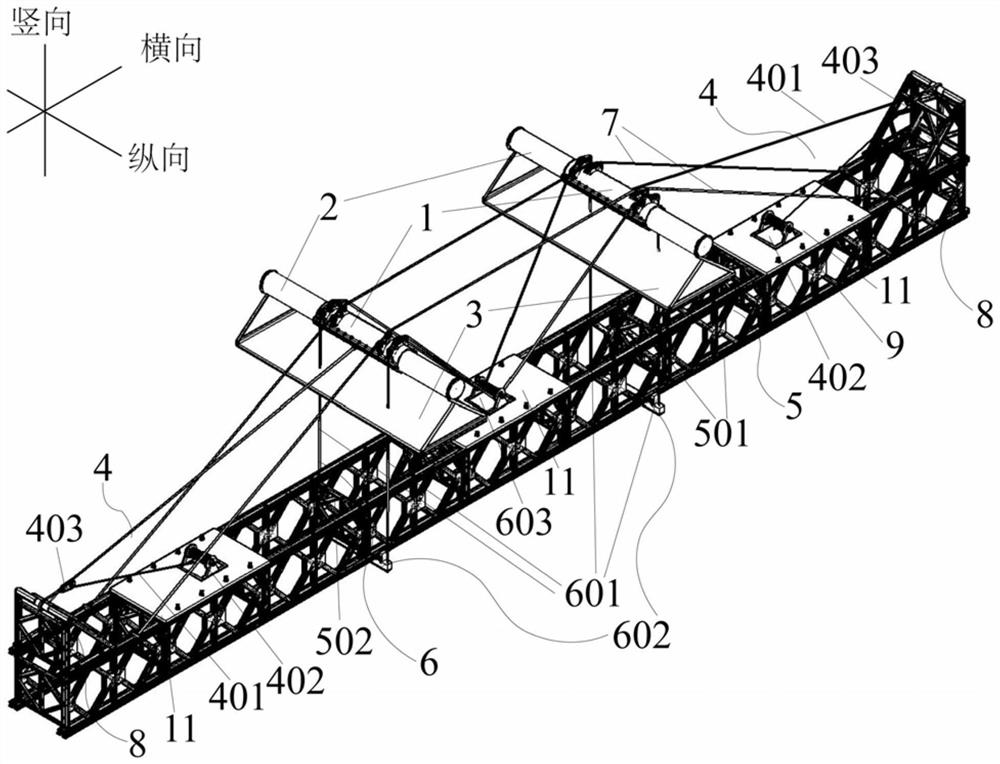

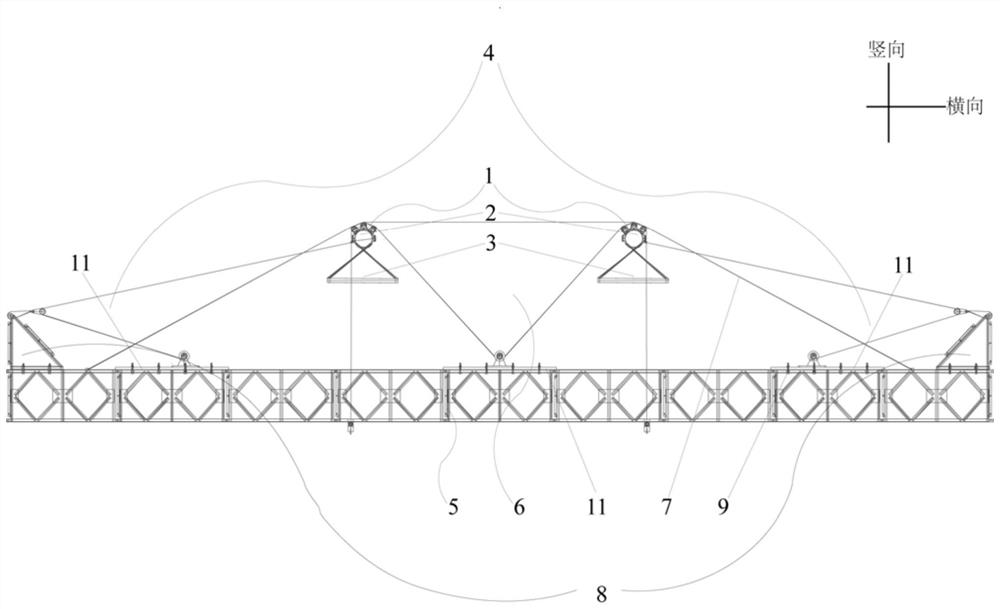

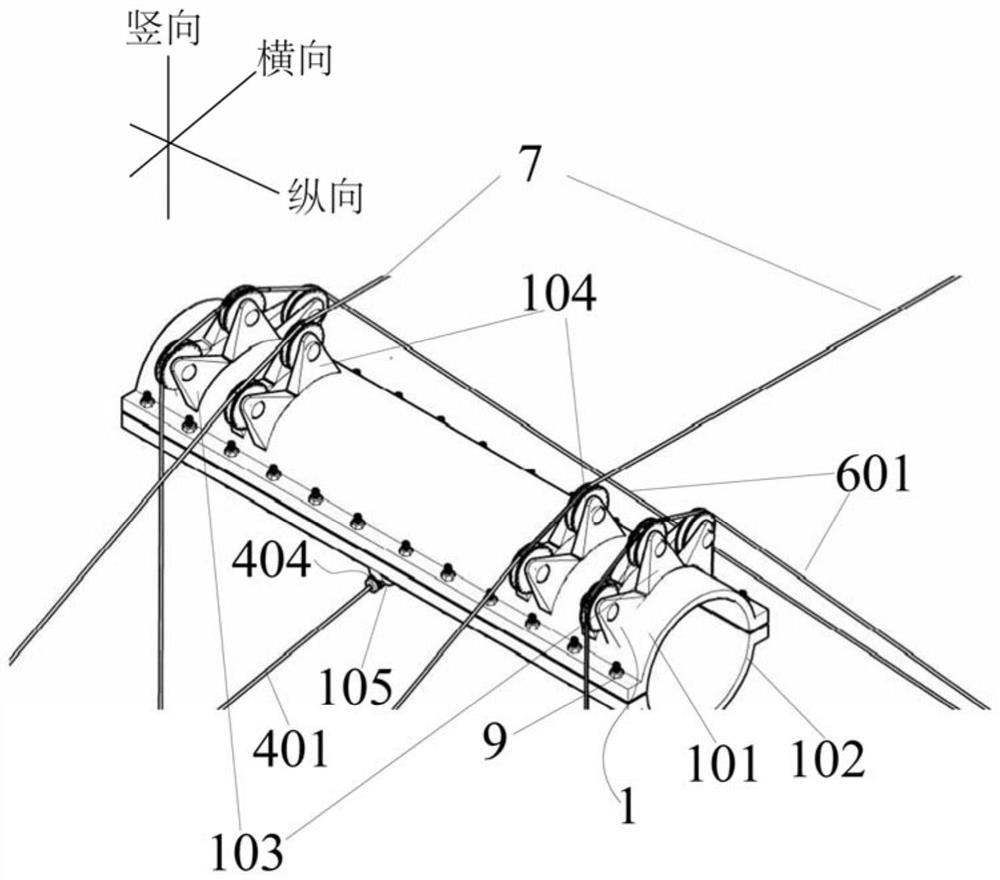

[0063] This embodiment provides a dynamic adjustment system for the lateral movement of the main cable of a suspension bridge, such as Figure 1 to Figure 10 As shown, a pair of main cable holding clips 1 are included, and a pair of main cable holding clips 1 are respectively arranged on a pair of main cables 2 in parallel and longitudinally opposite to each other, and a catwalk 3 is connected below the main cable 2; A transverse tensioning device 4 is fixedly installed on the upper surface, which is characterized in that a pair of transverse tensioning devices 4 are relatively fixedly installed on the top of the Bailey beam 5, and the Bailey beam 5 is located below the catwalk 3; the main cable 2 can be horizontally The lateral movement is carried out under the traction of the tensioning device 4;

[0064] A vertical support device 6 is arranged between a pair of lateral tensioning devices 4, and the vertical support device 6 is fixedly installed on the Bailey beam 5 and is a...

Embodiment 2

[0084] This embodiment provides a dynamic adjustment construction method. In this embodiment, the method adopts the dynamic adjustment system for the lateral movement of the main cable of the suspension bridge in Embodiment 1, and the method includes the following specific steps:

[0085] Step 1, Design and Assemble the Bailey Beam:

[0086] Design the length of the Bailey beam 5 according to the final linear shape required by the main cable 2 of the suspension bridge, assemble the designed Bailey beam 5, then fix the steel plate 11 on the top of the Bailey beam 5, and install the steel plate 11 on the top of the Bailey beam 5. A vertical support cable fixing part 602 is fixedly installed on the bottom end of the cable.

[0087] In this embodiment, the specific steps for installing the vertical support cable fixing portion 602 are: firstly install the roller 60203- in the roller bracket 60204, and then weld the inverted L-shaped blocks on the longitudinal ends of the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com