Two-way hydraulic jarring method and system for improving drill jamming treatment effect

A treatment effect, two-way hydraulic technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problem of difficult and flexible use of one-way hydraulic jars in complex well conditions, easy accidental excitation, fish falling accidents, etc. problem, to achieve the effect of improving the efficiency of accident handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

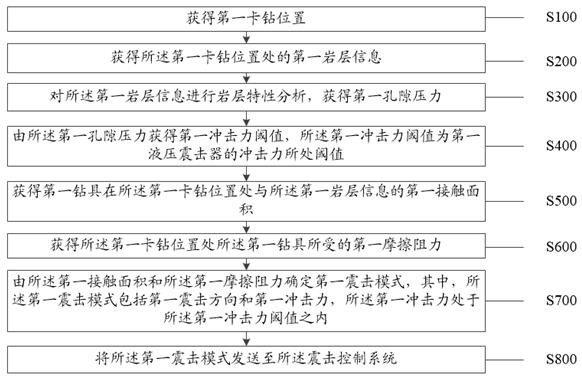

[0025] like figure 1 As shown, the embodiment of the present application provides a bidirectional hydraulic shock analysis method for improving the effect of stuck pipe treatment, wherein the method further includes:

[0026] Step S100: obtaining the first stuck position;

[0027] Specifically, during the drilling process, the phenomenon that the drilling tool is trapped in the well and cannot move freely due to various reasons is called stuck pipe. The jar is used while drilling to convert the potential energy inside the stretched drilling tool into kinetic energy. After the jarring occurs, this kinetic energy transmits a power wave to the stuck drilling tool, so that the With unlock card. Strata reasons, poor drilling fluid performance, and improper operation may all cause sticking. When a sticking accident occurs, it is necessary to analyze different situations in order to effectively relieve the stuck. The first sticking position is the specific position of the drill bi...

Embodiment 2

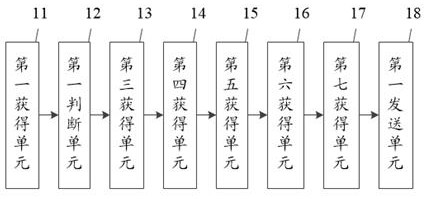

[0085] Based on the same inventive concept as the two-way hydraulic jarring method for improving the effect of sticking in the previous embodiment, the present invention also provides a two-way hydraulic jarring system for improving the effect of sticking, such as figure 2 As shown, the system includes:

[0086] a first obtaining unit 11, the first obtaining unit 11 is used to obtain the first stuck position;

[0087] a second obtaining unit 12, the second obtaining unit 12 is configured to obtain the first rock formation information at the first stuck pipe position;

[0088] a third obtaining unit 13, the third obtaining unit 13 is configured to perform rock formation characteristic analysis on the first rock formation information to obtain a first pore pressure;

[0089] a fourth obtaining unit 14, the fourth obtaining unit 14 is configured to obtain a first impact force threshold value from the first pore pressure, where the first impact force threshold value is a thresho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com