Improved structure of drum brake

A drum brake, a pair of technology, applied in the field of motorcycle and electric vehicle brake devices, can solve the problems of easy wear of brake cams, poor braking effect of drum brakes, and large sliding distance of vehicle brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

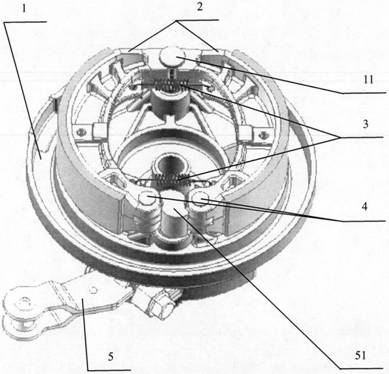

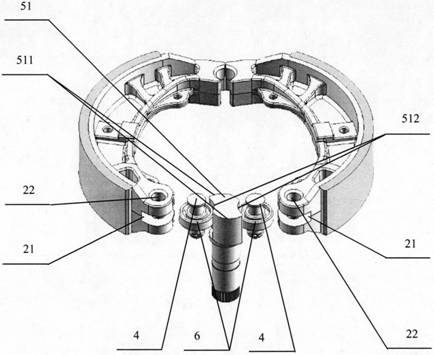

[0009] as attached figure 1 And attached figure 2 As shown, a pair of brake shoes (2) are installed in the housing (1), the elastic return element (3) is connected between the brake shoes (2), and one end of the pair of brake shoes (2) has a semicircle Arc surface, and is installed on the shaft (11), and can rotate around the shaft (11), and the shaft (11) is a part of the housing (1) structure; a pair of brake shoes (2) in the gap at the other end The components of the brake rocker arm assembly (5) are installed: the brake cam (51), the two sides of the brake cam (51) are respectively abutted with a bearing (6), and the bearing (6) is passed through by the rotating shaft (4) Its inner hole is installed in the shaft holes 22 of a pair of brake shoes (2), and when the brake rocker arm assembly (5) drives the brake cam (51) to rotate, the brake cam (51) drives the bearings on both sides (6) Rotate and move, and then drive a pair of brake shoes (2) to form an opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com