Liquid damper with damping force in direct proportion to displacement

A liquid damping and damping force technology, which is applied in the directions of liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems that the displacement of the piston rod of the damping force has no correlation, and the damping force cannot be generated, and achieves the change of the damping force, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

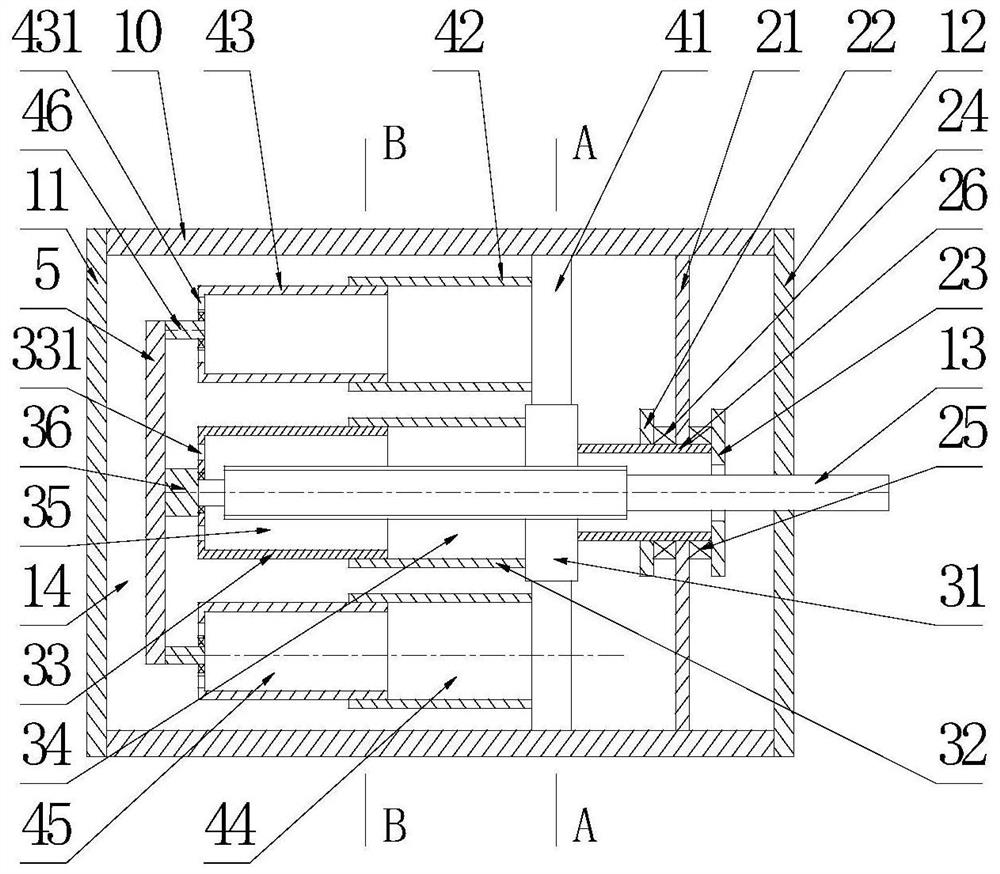

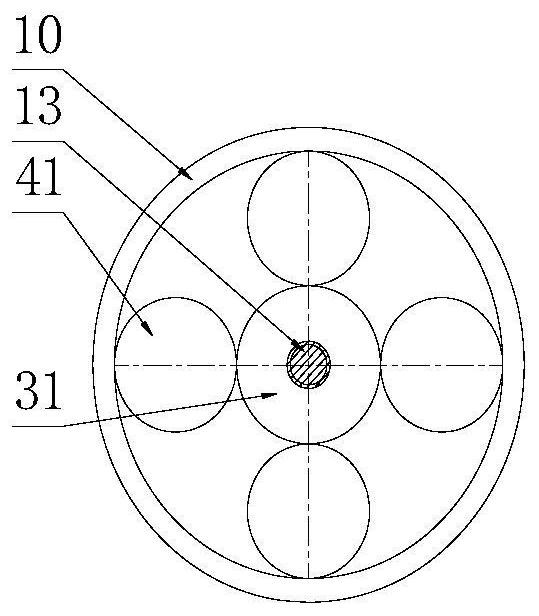

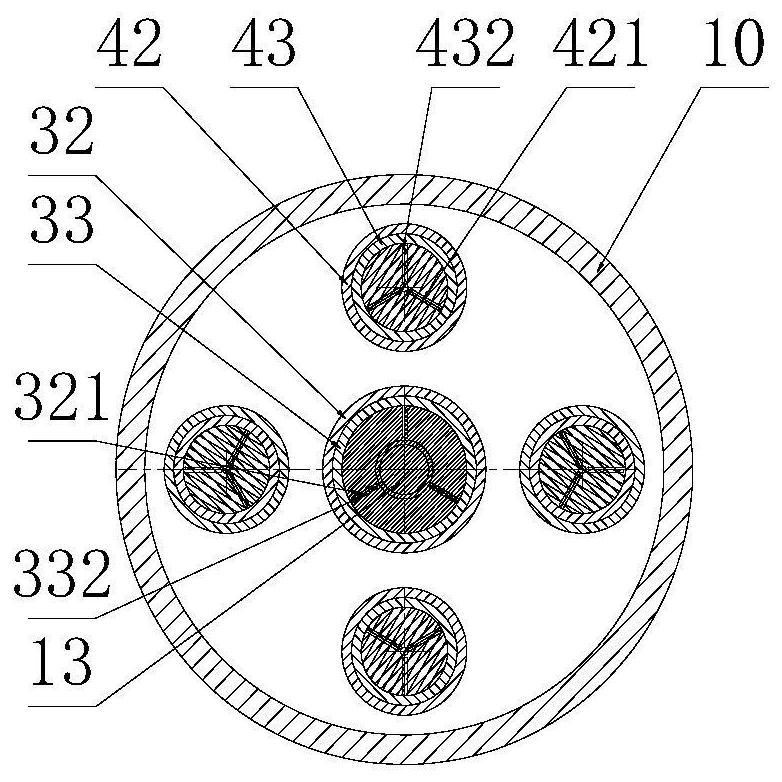

[0021] see figure 1 and figure 2 , a liquid damper in which the damping force is proportional to the displacement of the present invention, it includes a cylindrical hollow threaded cylinder 10 with internal threads on the inner wall, end caps A11 and end caps B12 installed at the left and right ends of the threaded cylinder 10, The left end is located inside the threaded cylinder 10 , and the right end extends through the end cover B12 to the threaded piston rod 13 outside the threaded cylinder 10 .

[0022] The middle part of the threaded piston rod 13 is provided with an external thread, and the two ends are polished rods; the inside of the threaded cylinder 10 is also equipped with a rotation damping device, four planetary damping devices with identical structures that can revolve around the rotation damping device, and a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com