Aircraft cylinder body detection machine

A detection machine and cylinder block technology, which is applied in the aviation field, can solve the problems of bumping and injury of inspectors, easy damage to the engine, limited test range, etc., and achieve the effect of improving service life, high degree of automation, high detection accuracy and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

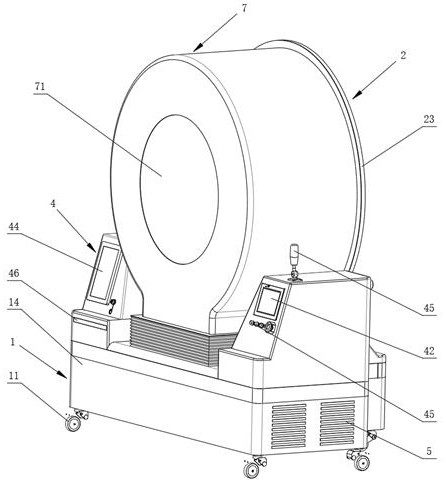

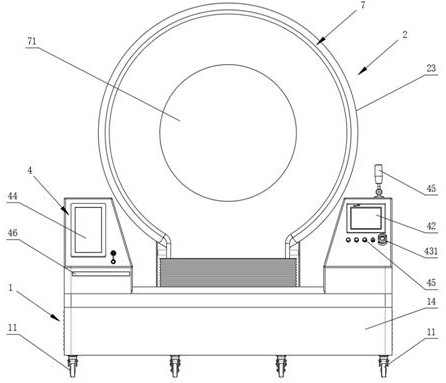

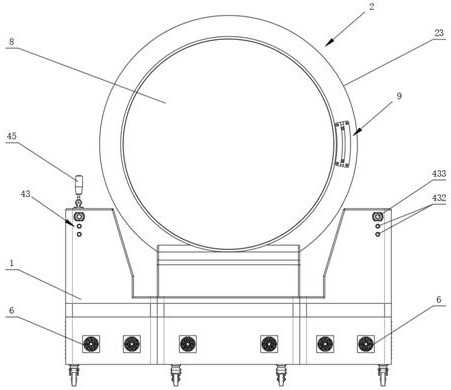

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] see Figures 1 to 11 , an aircraft cylinder detection machine, comprising a base 1, a detection unit 2 movable up and down connected to the back side of the base 1, a control host 3 arranged inside the base 1, the detection unit 2 includes a circular guide rail 21, a relative circular guide rail 21 Circumferentially rotating detection camera 22, described annular guide rail 21 is fixed on an annular guide rail fixed plate 23, and described guide rail fixed plate 23 cooperates with base 1 lifting; Described detection camera 22 is fixed on an end of an axial sliding mechanism 24 and can To move axially relative to the annular guide rail 21, the axial sliding mechanism 24 is connected to a radial sliding mechanism 25 and can move radially relative to the annular guide rail 21. The radial sliding mechanism 25 passes through a fixed plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com